B21, China Town Mall, Midrand

X91 Electro-Permanent Magnetic Chuck

- Section : Electrical & Tools

- Category : Machining

- SKU : 1600635327034

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the X91 Electro-Permanent Magnetic Chuck?

The X91 is an electro-permanent magnetic chuck designed for high-precision clamping during CNC machining and milling. It provides strong, reliable workpiece holding with options for custom sizes and OEM/ODM/OBM support.

2. What materials can the X91 clamp?

The X91 clamps ferromagnetic materials (iron, steel, cast iron) directly. Non-ferrous materials (aluminum, stainless grades with low permeability, brass, etc.) require a ferromagnetic backing plate or fixture to be held.

3. What is the holding force of the X91?

Rated holding force is 160 N/cm² (suction/holding pressure). Actual holding capacity depends on part material, surface finish, contact area and pole pitch.

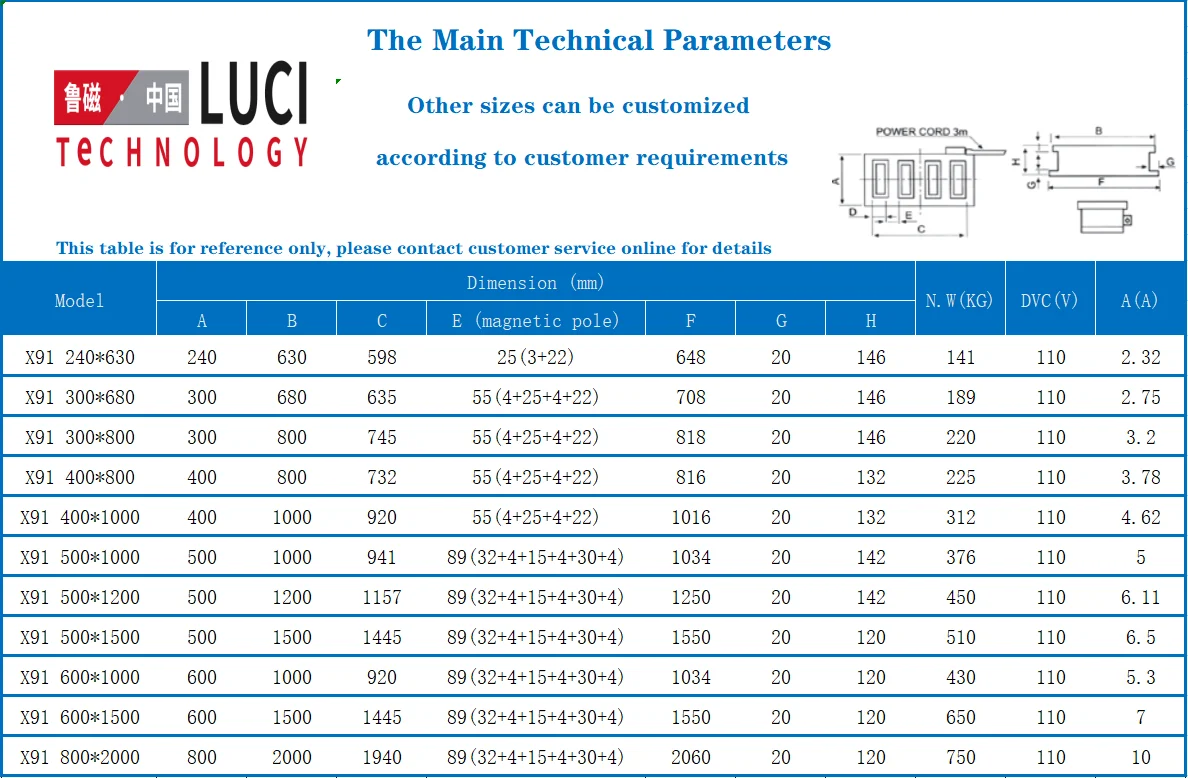

4. What are the physical dimensions and weight of the standard X91 unit?

Standard unit size: 240 mm × 480 mm × 110 mm. Packed size: 350 × 680 × 160 mm. Net weight: 65 kg.

5. What are the electrical power requirements?

The supplied specification lists DVC: 110 V and A: 2.3 A. As an electro-permanent device, it requires a short electrical pulse to switch ON/OFF; it does not require continuous power to maintain clamping once set.

6. How does the electro-permanent magnetic system work?

Electro-permanent chucks use an electrical pulse to switch magnetic circuits between magnetized and demagnetized states. After the brief pulse, the magnetic state is maintained without continuous power, providing fail-safe holding during power loss.

7. What is the magnetic pole pitch and why does it matter?

Pole pitch is 55 mm (configured as 4+25+4+22 mm). Pole pitch affects contact conformity, clamping distribution and suitability for small/irregular parts — smaller pitch gives better conformity for small workpieces.

8. What installation and fixturing options are available?

The X91 supports two installation options for presser foot and punch to secure thin or odd-shaped parts. Specific mounting details and hole patterns are customizable — provide your machine mounting requirements to the supplier.

9. Is the X91 suitable for CNC machining centers and milling machines?

Yes. The X91 is designed specifically for use in milling machines and CNC machining centers where stable, repeatable, high-precision clamping is required.

10. Can the X91 be customized to my size or specification?

Yes. OEM, ODM and OBM customization are supported. Size and specification can be custom made — contact the manufacturer with drawings or requirements for a quote and lead time. MOQ is 1 set.

11. What warranty and after-sales support are provided?

Each X91 chuck comes with a 1-year warranty. For warranty claims, spare parts, repairs or technical support, contact the supplier or distributor with the unit serial and purchase information.

12. How is the X91 packaged and shipped?

Units are shipped in a wooden box; sea (ocean) transportation is offered for timely and cost-effective global delivery. Supply capacity is listed as 180 sets per month. For exact lead times and freight options, contact sales.

13. What maintenance is required to keep performance and longevity?

Keep the pole surface clean and free of chips, coolant and rust. Avoid heavy impacts or dropping the chuck. Inspect electrical connections and coil insulation periodically. If machining generates sparks or grinding, protect the pole face and follow safe demagnetization procedures prior to abrasive operations.

14. What are the coil materials and can coils be replaced?

Coils use copper and aluminum wire. Replacement coils or repair services are available — contact the manufacturer or authorized service center for spare parts, repair instructions and authorized service procedures.

15. What safety precautions should I follow when using the X91?

Disconnect the power supply before servicing. Ensure correct commissioning and grounding per machine/electrical codes. Keep ferromagnetic debris away from the pole face, use presser feet/punches for thin parts, and confirm workpiece stability before machining. For detailed safety guidance consult the manufacturer manual.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading