No products in the cart.

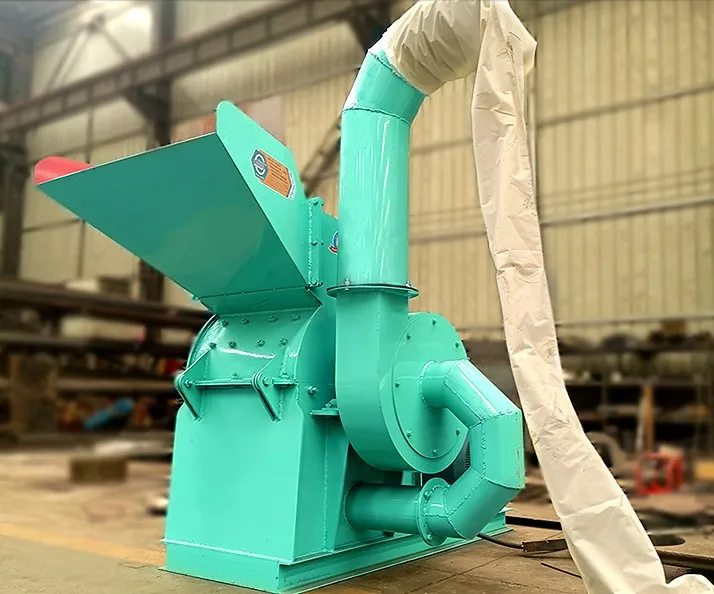

Low cost Wood Chipper Pulverizer Wood Pellet Mill Machine Tree Branch Shredder Wood Into Sawdust Machine

R98,500 Excl VAT

Find out how...

PayJustNow is a simple, easy-to-use payment system.

Here’s how it works:

PayJustNow allows you to pay for your purchase over 3 equal, zero interest instalments. You’ll pay one instalment at the time of purchase, the next at the beginning of the following month and the last one a month thereafter.

#zerointerest

Step 1:

Browse your favourite online stores and proceed to check-out.

Step 2:

Choose PayJustNow as your payment method.

Step 3:

Create your account as easily as if your eyes were shut (though we’d recommend you keep them open).

Step 4:

Complete your purchase and whoop for joy!

Here’s what you’ll need:

A valid RSA ID document

To be over 18 years old

An email address

A SA Bank issued debit or credit card

Product Overview

Industrial Wood Tree Branches Crusher Wood Logs Sawdust Hammer Mill biomass fuel production crusher for making wood pellets

A wood hammer mill is a machine used to shred or crush wood materials into small pieces. It is commonly used in wood processing plants, biomass fuel production, and other industries that require wood particles to be reduced in size.

The size of the wood particles produced by the hammer mill can be controlled by adjusting the size of the openings on the screen that covers the discharge outlet. Different screen sizes can produce different particle sizes, allowing the wood hammer mill to be used for a variety of applications.

Working Principle of a wood hammer mill .

It involves a combination of impact and cutting forces to break down wood materials into smaller pieces. Here is a step-by-step guide to how a wood hammer mill works: Feeding: The wood material is fed into the wood hammer mill through a feeding hopper or conveyor. The material is then moved to the grinding chamber by the rotating blades of the hammer mill. Grinding: The wood material is ground up by the rotating blades, which impact and cut the material into smaller pieces. The hammer mill operates at high speed, typically ranging from 1,800 to 3,600 RPM. Sieving: Once the wood material is ground up, it passes through a screen or sieve to separate the smaller particles from the larger ones. The size of the screen determines the size of the wood particles that are produced. Discharge: The wood particles are discharged from the wood hammer mill through a discharge chute or conveyor. The smaller particles can be used directly, while larger particles may need to be processed further. Maintenance: Regular maintenance is required to keep the wood hammer mill functioning properly. This includes cleaning the machine, checking for wear and tear on the blades and screens, and lubricating moving parts. Overall, the working principle of a wood hammer mill involves a combination of impact and cutting forces to break down wood materials into smaller pieces, which can be used for a variety of purposes, including fuel, animal bedding, and wood composite materials.

Details Images

Advantages of using a wood hammer mill in wood processing industries, including:

1.Size reduction: A wood hammer mill is designed to break down wood materials into smaller pieces, making it easier to handle,transport, and process. Reducing the size of the wood particles, it also increases the surface area, making it easier for chemical Processes such as drying and combustion to occur.

2.Versatility: A wood hammer mill can process a variety of wood materials, including softwood and hardwood, as well as other wood products such as wood chips, sawdust, and wood shavings. This makes it a versatile machine that can be used in a range of wood processing applications.

3.fficiency: A wood hammer mill can process large volumes of wood materials quickly and efficiently, reducing processing time and labor costs. It can also reduce waste by turning wood scraps and waste into usable products, such as wood pellets, which can be used as fuel.

4.Customization: Wood hammer mills can be customized to meet specific processing requirements, such as the desired particle size, feed rate, and moisture content. This allows them to be used in a variety of wood processing applications, from producing wood pellets for fuel to creating wood flour for use in composite materials.

5.Durability: Wood hammer mills are designed to withstand heavy use and are constructed with durable materials such as steel, making them a long-lasting investment for wood processing companies.

6.Environmental benefits: Using a wood hammer mill to process wood waste and scraps can help to reduce waste and promote sustainability. By converting wood waste into usable products, it reduces the need for landfill space and helps to conserve Natural resources.

Overall, the advantages of using a wood hammer mill in wood processing industries are numerous, including increased efficiency, versatility, customization, and environmental benefits..

|

Model

|

Power

|

Capacity (kg/h)

|

Dimension

|

Weight

|

|

600

|

37 kw

|

800-1200

|

2.4*1.2*1.4m

|

1500 kg

|

|

800

|

45kw

|

1500-2000

|

2.7*1.2*1.5m

|

2200 kg

|

|

1000

|

75 kw

|

3000-4000

|

2.8*1.2*1.5m

|

3200kg

|

|

1200

|

90kw

|

5000-6000

|

3.1*1.2*1.65m

|

4000kg

|

|

1500

|

132 kw

|

8000-10000

|

3.5*1.2*1.6m

|

5500kg

|

Additional information

| Model Number | QFS-800 |

|---|

Reviews

There are no reviews yet.