B21, China Town Mall, Midrand

Automatic Walking Hydraulic Milling Machine

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600973256039

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 25 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Automatic Walking Hydraulic Milling Machine?

A self-propelled milling machine for surface removal and profiling of concrete and asphalt, featuring hydraulic drive, an automatic walking system, and adjustable milling depth.

2. What surfaces and applications is this machine suitable for?

Road and pavement milling, concrete surface preparation, removal of markings and coatings, trenching for utilities, repair of small damaged areas — suitable for multiple venues such as streets, parking lots and construction sites.

3. What type and size of cutting tools does it use?

Uses tungsten steel alloy hobs with 60 mm diameter blades. Typical configurations list 108–120 blades mounted on the cutter drum; blades are designed to be firm and resistant to falling off.

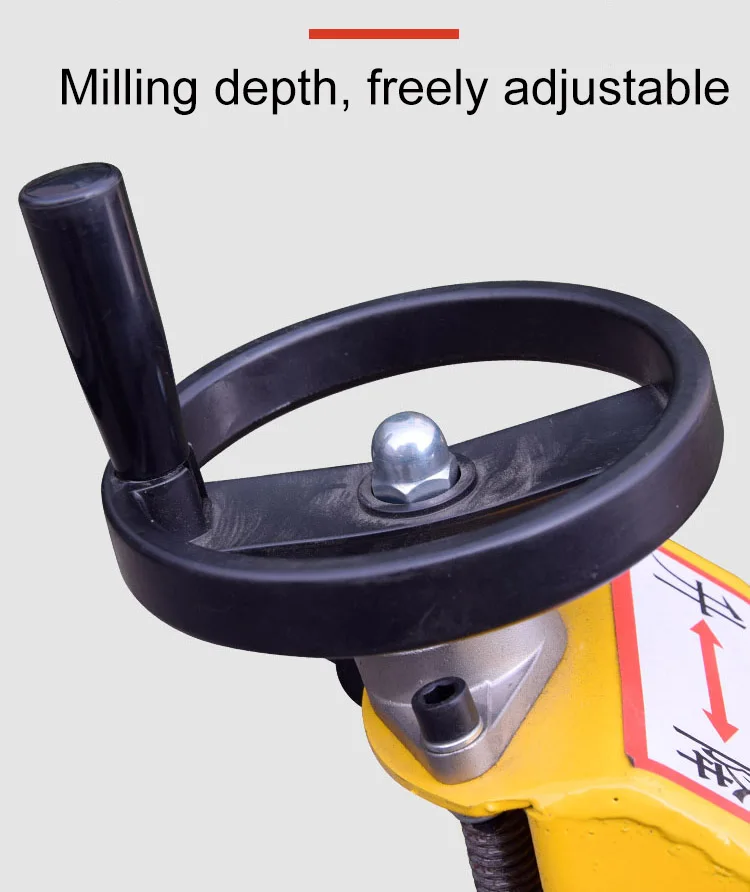

4. What is the adjustable milling depth?

The milling depth is adjustable from 0 to 15 mm. The lifting handle wheel provides stable, fine control of the ground milling depth (effective fine adjustment up to about 8 mm).

5. What power options and motor ratings are available?

Available in gasoline, diesel and electric power types. Motor power (efficiency) ranges around 5.5 kW to 7.5 kW. Gasoline models reference air-cooled engines (e.g., model series listed as 390-186).

6. What are the machine's main dimensions and weight?

Cutting width/model is listed as 250–300 mm. Machine weight typically ranges from 140 to 160 kg, depending on configuration and power option.

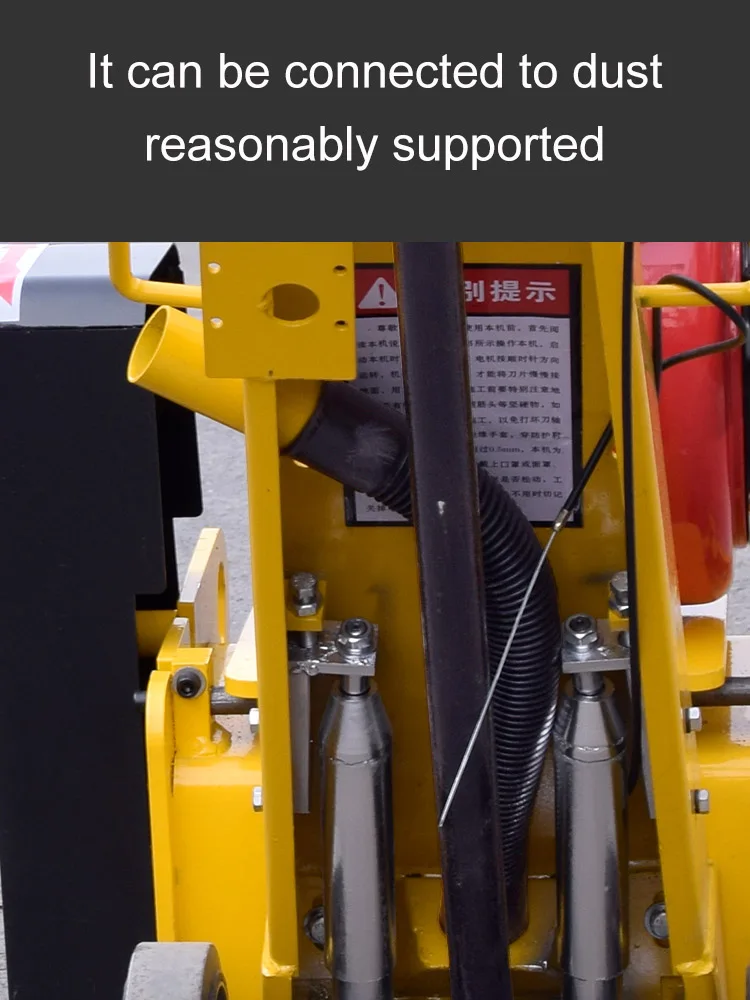

7. Can the machine be connected to a vacuum or dust-extraction system?

Yes — the machine can be connected to an external vacuum cleaner or dust-extraction system to reduce airborne dust during milling.

8. How durable and robust is the machine?

It has a thickened fuselage that's resistant to deformation, a stable center of gravity, solid walking wheels for wear resistance, and generally longer service life when properly maintained.

9. How easy is it to move and steer the machine on site?

Equipped with solid walking wheels and a universal adjustment wheel for flexible steering. The automatic walking system and ergonomic controls make on-site movement and positioning convenient.

10. What routine maintenance is required?

Regularly inspect and replace worn blades, check and tighten cutter bolts, lubricate moving parts per the manual, clean the cutter drum and vacuum port, and follow engine maintenance (oil, filters, spark plugs) for gasoline/diesel models.

11. What safety precautions should operators take?

Wear proper PPE (ear protection, eye protection, dust mask or respirator, gloves), ensure good ventilation for gasoline/diesel use, check guards before use, secure work area, switch off and disconnect power before servicing, and do not exceed recommended milling depths.

12. Are spare parts and replacement blades available?

Yes. Replacement tungsten carbide/tungsten steel blades and common spare parts are typically available — contact the supplier for part numbers, lead times and compatible kits.

13. How noisy or polluting is the machine?

Gasoline and diesel models produce significant noise and exhaust emissions and require hearing protection and ventilation. Electric models operate quieter and with zero local emissions.

14. How should the machine be transported and stored?

Given its 140–160 kg weight, use a suitable lift, pallet or vehicle ramp for transport. Secure the unit during transit. Store in a dry, sheltered area and follow winterization and engine storage procedures if applicable.

15. What warranty and support can I expect?

Warranty terms, service intervals and on-site support vary by supplier and region. Contact the seller or manufacturer for specific warranty coverage, authorized service centers and after-sales support options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading