B21, China Town Mall, Midrand

LM Continuous Fiber Laser Welding Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600923328534

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the LM Continuous Fiber Laser Welding Machine?

A fiber laser welding system designed for efficient metal joining in industrial applications. It offers high-quality welds, a robust build, adjustable parameters (including pulse width), and options for welding, cutting and cleaning via dedicated or integrated heads.

2. What power options are available?

Standard models are available in 1000W, 1500W and 2000W. A 3000W option is also offered on some configurations—confirm available power variants with your supplier.

3. Which materials can this machine weld?

It can weld stainless steel, carbon steel and many other metals, and is also suitable for aluminum and common industrial alloys depending on the chosen parameters and optics.

4. What is the laser wavelength and laser source brand options?

The typical fiber laser wavelength is 1070 nm. Laser source brands offered include Raycus, IPG, JPT, BWT and RECI; final configuration depends on the ordered model.

5. How does the adjustable pulse width help welding?

Adjustable pulse width allows precise control of heat input and penetration, reducing distortion, improving seam appearance and enabling optimization for different material thicknesses and joint types.

6. What cooling system does the machine use?

The machine uses a water cooling system to maintain stable operating temperatures for the laser source and optics. A compatible water chiller and routine coolant maintenance are required.

7. Is the system handheld or automated?

The system supports a user-friendly handheld welding gun for manual operation and can also be integrated with program-controlled robots for automated or complex welding routines.

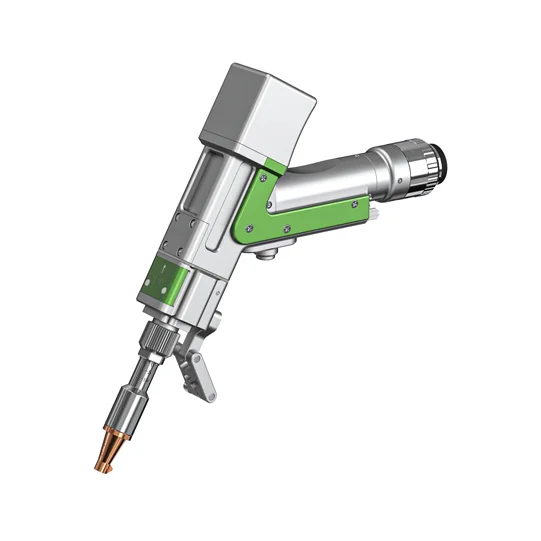

8. What are the handheld gun and fiber cable specifications?

Typical handheld gun weight is about 1.2 kg. Standard fiber cable lengths offered include 10 m and 20 m, with 15 m available as an option—confirm the supplied length when ordering.

9. What are the electrical requirements?

Typical main power supply is 380V, 50/60 Hz (three-phase). Some documentation also references 220V for certain control circuits or regional variants—confirm exact electrical requirements for your model and local installation.

10. What is the machine weight and how portable is it?

The machine weighs approximately 230 kg. It is sturdy and manageable for workshop settings but not handheld as a whole—use equipment such as a pallet truck or forklift for relocation and ensure a stable installation area.

11. What is the welding speed and adjustable laser width?

Welding speed range is 0–120 mm/s. The adjustable laser width can be set from 0 to 80 mm to suit different seam sizes and application needs.

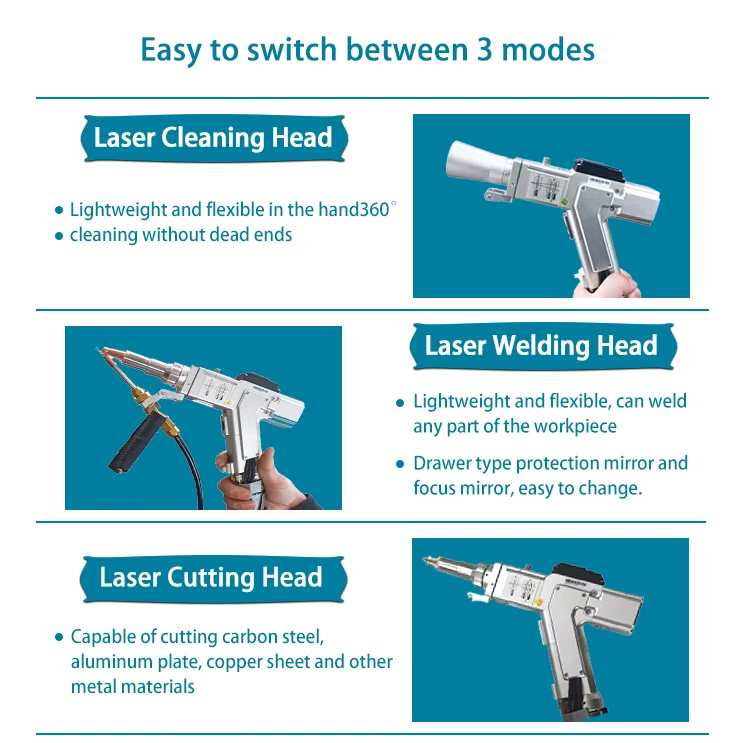

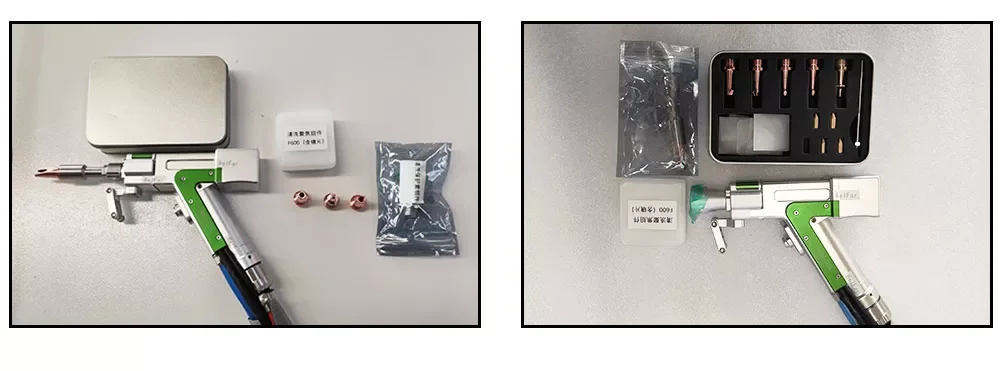

12. What heads and gun tip brands are available?

Available heads include laser welding, cutting and cleaning heads, plus 4-in-1 multifunction heads that switch between functions. Gun tip/optics brands offered include Rulfar, Au3tech, RayTools and Hanwei.

13. What maintenance is required?

Regular maintenance includes keeping optics clean, replacing protective lenses or seals as needed, maintaining the water chiller and coolant quality, inspecting fiber connections, and following manufacturer-specified service intervals.

14. What safety precautions should be followed?

Always wear appropriate laser safety eyewear, use proper shielding and warning signage, provide ventilation for fumes, use interlocks where applicable, and follow local laser safety regulations. Confirm required PPE and training with the supplier.

15. What after-sales support and warranty are provided?

The product listing indicates online support is available. Warranty terms, response times and spare-parts availability vary by supplier—confirm warranty length, included support services and spare-parts policy before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading