B21, China Town Mall, Midrand

2 Head 9 12 15 Pins Type Computerized Embroidery Machine

- Section : Machinery

- Category : Embroidery Machines

- SKU : 1600817628204

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What does "2 Head" mean for this embroidery machine?

"2 Head" means the machine has two independent embroidery heads, allowing you to stitch two identical or different designs simultaneously to double production output compared with a single-head machine.

2. What do the "9 12 15 Pins Type" options refer to?

The 9, 12, and 15 pins refer to the number of needles (colors) per head. Choosing a 9-, 12- or 15-needle configuration determines how many thread colors you can use without rethreading.

3. What is the maximum embroidery speed?

The machine's maximum speed is 1000 RPM. Actual stitch speed will depend on design complexity, stitch length settings and fabric type.

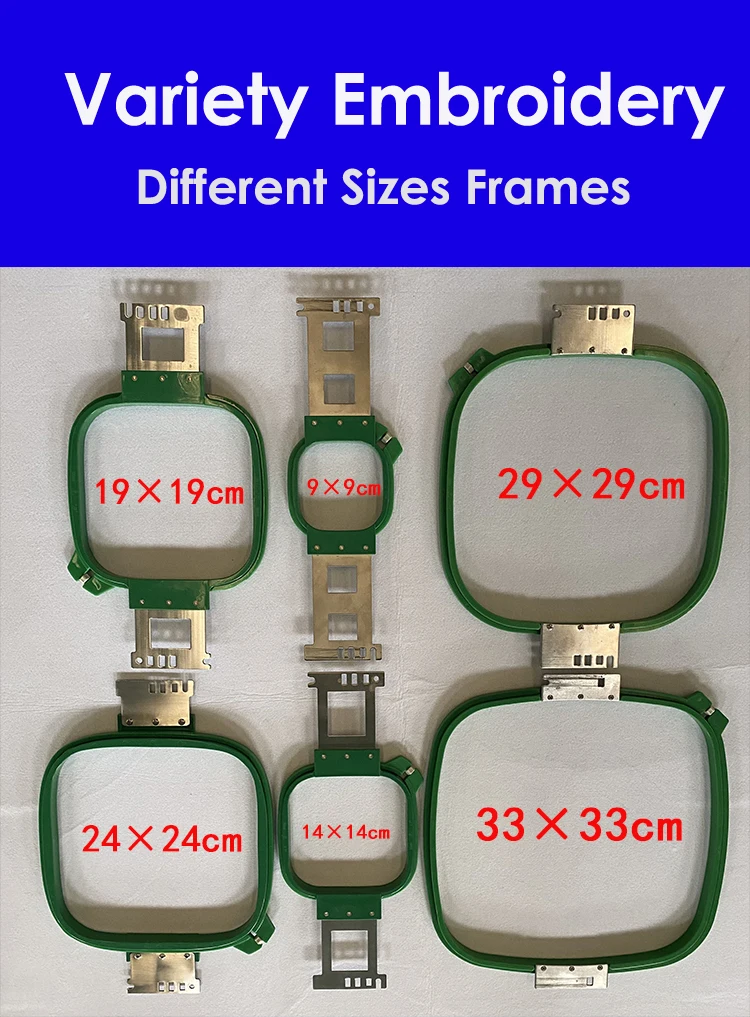

4. What embroidery area and worktable size does it support?

The embroidery area and worktable size are 400 x 500 mm (15.7 x 19.7 in), which is the maximum hoop size for each head on this model.

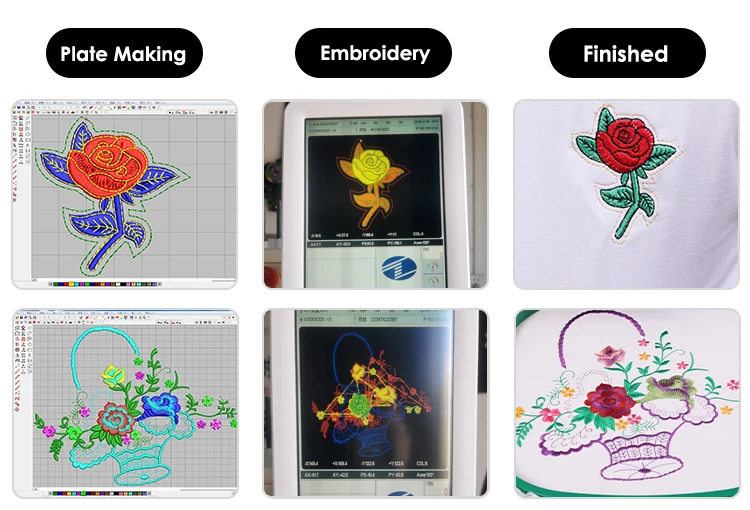

5. Which file formats and design software are supported?

The control accepts Tajima DST format files. The machine is compatible with common embroidery design software such as Wilcom. Confirm the preferred file transfer method (USB/PC) with the supplier.

6. How much memory does the machine have and how many designs can it store?

Standard memory is 1 million stitches (expandable up to 2 million stitches depending on configuration), and the controller can store up to 99 designs internally.

7. What are the electrical requirements and power consumption?

This machine is designed for single-phase 220V/50Hz power and consumes about 600 W. Verify your local voltage and provide a stable power source with surge protection.

8. Can this machine do flat, cap and garment embroidery?

Yes — it supports three functions in one: flat embroidery, cap embroidery and general garment embroidery. Cap frames and specific accessories may be required for cap work; check which accessories are included.

9. What is the head interval and why does it matter?

The head interval (distance between heads) is 330 mm. This determines clearance between heads for larger items and affects how multi-head setups align when embroidering larger or wrapped items.

10. What are the machine's physical dimensions and weight for installation planning?

Overall dimensions are approximately 146 x 93 x 106 cm and net weight is about 260 kg. Crated dimensions and shipping weight will be larger — plan for a pallet, forklift access and sufficient floor space.

11. What core components are used and what spare parts should I keep on hand?

Core components include the motor and main control board. Common consumables/spares to keep include needles, bobbins, presser feet, belts, fuses and spare needles/threads. Ask your supplier about an OEM spare-parts kit.

12. Are quality checks or test reports provided before shipping?

Yes. A machinery test report and a video of the outgoing inspection are provided to verify performance and build quality prior to shipment.

13. Is training or a user manual provided and how easy is the machine to operate?

The machine is described as easy to operate. Most suppliers provide a user manual and may offer training (onsite or remote). Confirm training availability and language with your vendor.

14. What maintenance is required to keep the machine running well?

Regular maintenance includes cleaning lint and dust, lubricating moving parts per the manual, replacing needles and bobbins as needed, checking thread tension, and periodic inspection of belts and electronics. Follow the manufacturer's maintenance schedule.

15. What warranty and after-sales support are available?

Warranty terms and after-sales support vary by supplier and region. Ask your vendor about the length and coverage of the warranty, availability of spare parts, technical support and service options before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading