B21, China Town Mall, Midrand

ZXSMART 4L 5L Bottle Packaging Automatic Liquid Detergent Liquid Fertilizer Filling Machine

- Section : Machinery

- Category : Filling Machines

- SKU : 1600693687282

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of liquids can the ZXSMART filling machine handle?

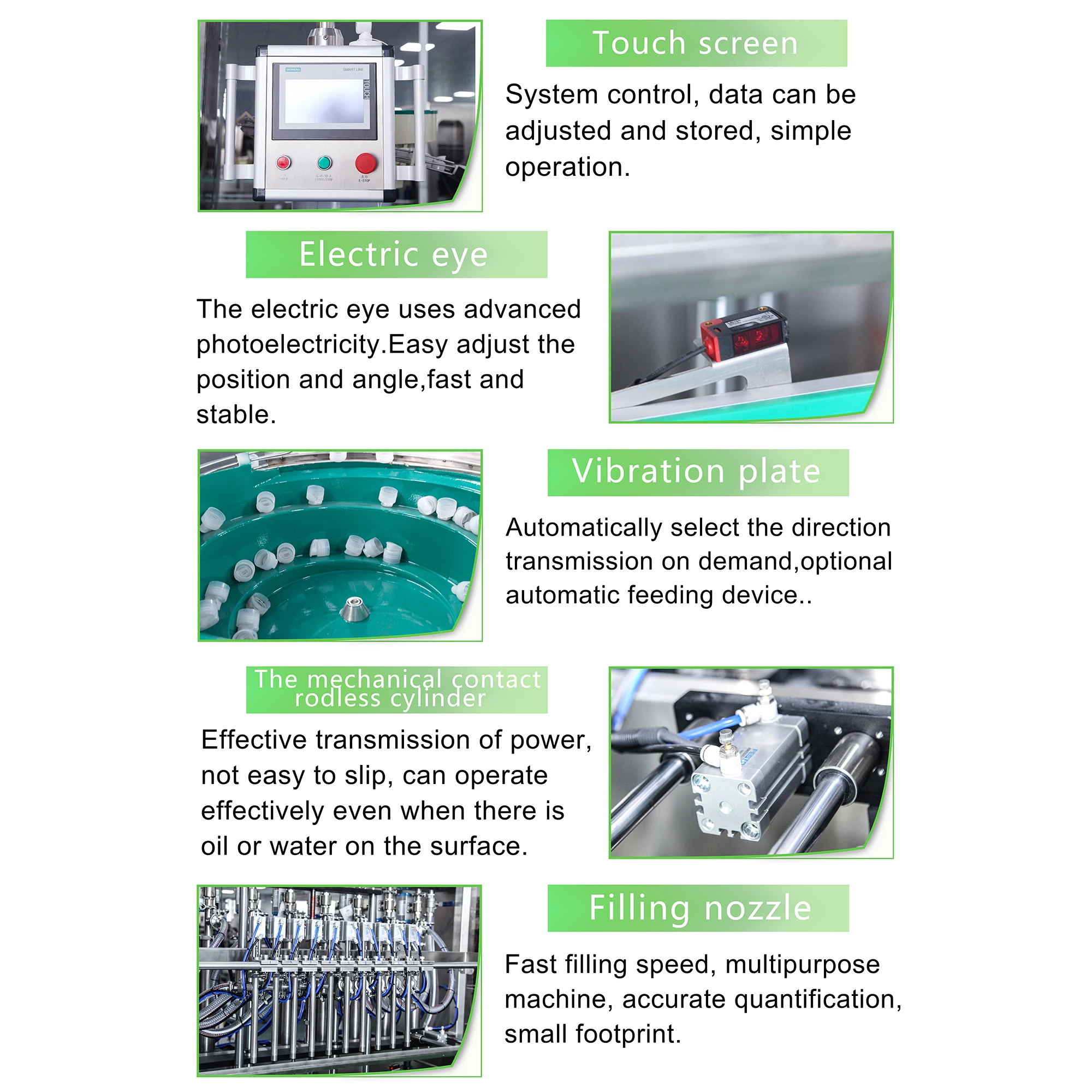

Designed for liquid detergents and liquid fertilizers, the servo piston multi-head system can also handle other low-to-medium viscosity liquids and many chemical solutions. For very high-viscosity, abrasive or heavily foaming liquids, please consult us for nozzle/pump adjustments or special materials.

2. What is the filling range and accuracy?

Filling capacity is adjustable from 50 ml up to 5,000 ml (customizable). Standard filling accuracy is ±1% when properly calibrated.

3. How fast does the machine fill bottles?

Standard performance is up to 50 bottles per minute for 500 ml containers. Actual speed varies with bottle size, product viscosity, number of heads and configuration; multi-head options can increase throughput.

4. How many filling heads does the machine have and can this be changed?

The machine comes with 10 filling heads by default, and head count can be customized to meet your production requirements.

5. What capping methods and speeds are supported?

Capping options include a vibrating plate (automatic) and manual capping. Typical capping speeds range from 30–50 bottles per minute depending on cap type and operator settings.

6. What materials are used for product contact and machine frame?

Product-contact parts and the filling frame are made of 304 stainless steel for corrosion resistance, durability and easy cleaning.

7. What are the machine's power and air requirements?

Standard power requirement is 3.5 kW, 380 V three-phase five-wire. Compressed air requirement is 0.6–0.8 MPa. Specific electrical configurations can be adapted on request.

8. What are the machine dimensions and weight?

Without conveyor belt: 2200 × 1400 × 2100 mm. With conveyor belt: 4000 × 1400 × 2100 mm. Approximate weight is 800 kg.

9. Can the machine handle different bottle and barrel sizes?

Yes — filling volume, head spacing and fixtures are adjustable to accommodate a wide range of containers from small bottles up to 5 L barrels. Please provide sample containers so we can configure the machine correctly.

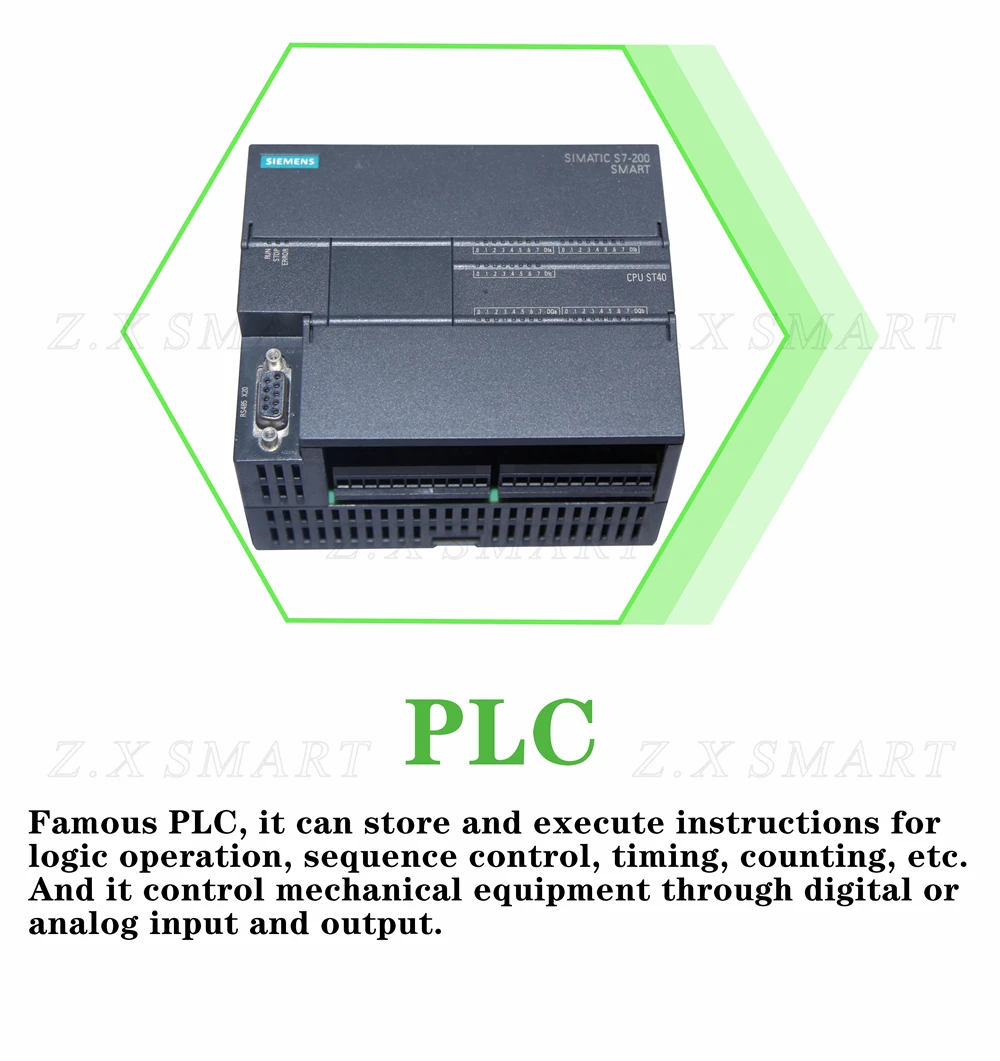

10. Is the machine easy to operate and control?

Yes — it features PLC control with a touch screen HMI for recipe storage, parameter adjustment and real-time monitoring, enabling user-friendly and repeatable operation.

11. What maintenance and cleaning procedures are recommended?

Daily checks: clean nozzles and product-contact surfaces, inspect seals and hoses. Weekly/monthly: lubricate moving parts per manual, check pump and piston seals, tighten fasteners and verify calibration. CIP (clean-in-place) can be arranged as an option for frequent product changeovers.

12. Do you provide installation, commissioning and operator training?

Yes – installation, commissioning and operator training can be provided onsite or remotely upon request. Details and costs depend on location and scope; please contact us to arrange.

13. What warranty and after-sales support are offered?

The machine carries a 3-year warranty. After-sales support includes spare parts supply, technical support and maintenance services. Specific warranty terms are provided in the sales agreement.

14. Can the machine be customized or integrated into an existing production line?

Yes — we offer customization for filling heads, capacity, capping systems, conveyors and integration with upstream/downstream equipment. Tell us your layout and process requirements so we can propose a solution.

15. What certifications and safety standards does the machine meet?

The machine is built to industrial safety and hygiene standards. Certifications (CE, ISO, etc.) and specific compliance documentation can be provided on request depending on customer needs and destination market.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading