B21, China Town Mall, Midrand

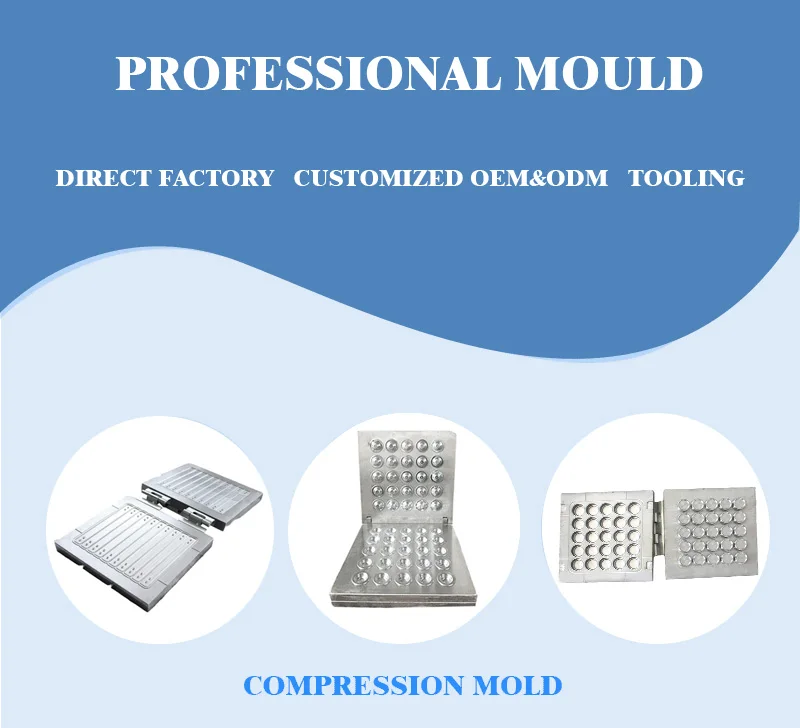

XHW Rubber Compression Mould

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1600283108412

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials are used in the construction of the XHW Rubber Compression Mould?

The XHW Rubber Compression Mould is constructed from high-quality materials including P20, S718, #45, and #50 steel, ensuring superior strength and durability.

2. What is the operational lifespan of the XHW Rubber Compression Mould?

The mould can withstand between 50,000 to 500,000 shots, depending on the material and application, providing a long operational life.

3. Can the XHW Rubber Compression Mould be customized?

Yes, the mould is fully customizable, allowing you to produce rubber parts in any size according to your specific requirements.

4. What is the lead time for ordering the XHW Rubber Compression Mould?

The lead time for the XHW Rubber Compression Mould is typically 15-25 days, depending on the complexity of the product.

5. Is the XHW Rubber Compression Mould suitable for high-volume production?

Yes, the XHW Rubber Compression Mould is ideal for producing high-volume rubber components efficiently.

6. What configuration options are available for the XHW Rubber Compression Mould?

You can choose between single or multi-cavity configurations, depending on your production needs, with the multi-cavity option allowing for increased efficiency.

7. How is the XHW Rubber Compression Mould packaged for shipping?

The mould is carefully packed in a wooden box or carton to ensure safe shipping and handling.

8. Does XHW offer OEM services for the Rubber Compression Mould?

Yes, XHW welcomes OEM orders and is open to customization to meet your specific design and production needs.

9. What design file formats does XHW accept?

XHW accepts various design file formats including STP, IGS, and CAD for seamless collaboration and design implementation.

10. What types of applications can the XHW Rubber Compression Mould be used for?

The mould is suitable for a variety of applications where precision and quality are key, including the production of small rubber components and large quantities of parts.

11. What are the benefits of using the XHW Rubber Compression Mould?

The XHW Rubber Compression Mould offers durability, efficiency, customizable sizes, and fast lead times, making it a reliable solution for rubber molding needs.

12. Is the XHW Rubber Compression Mould suitable for beginners in rubber molding?

While the mould is designed for efficiency and precision, it is best suited for users with some experience in rubber molding processes.

13. Can I order a sample before committing to a larger order of the XHW Rubber Compression Mould?

Please contact XHW directly to inquire about sample orders and any associated costs.

14. What types of rubber products can be made using the XHW Rubber Compression Mould?

The mould is perfect for producing a wide range of rubber products, from small components to larger parts, depending on your specific requirements.

15. What is the expected quality of the products made with the XHW Rubber Compression Mould?

The mould ensures precise, high-quality results for a variety of rubber products, maintaining the standards required for demanding applications.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals