B21, China Town Mall, Midrand

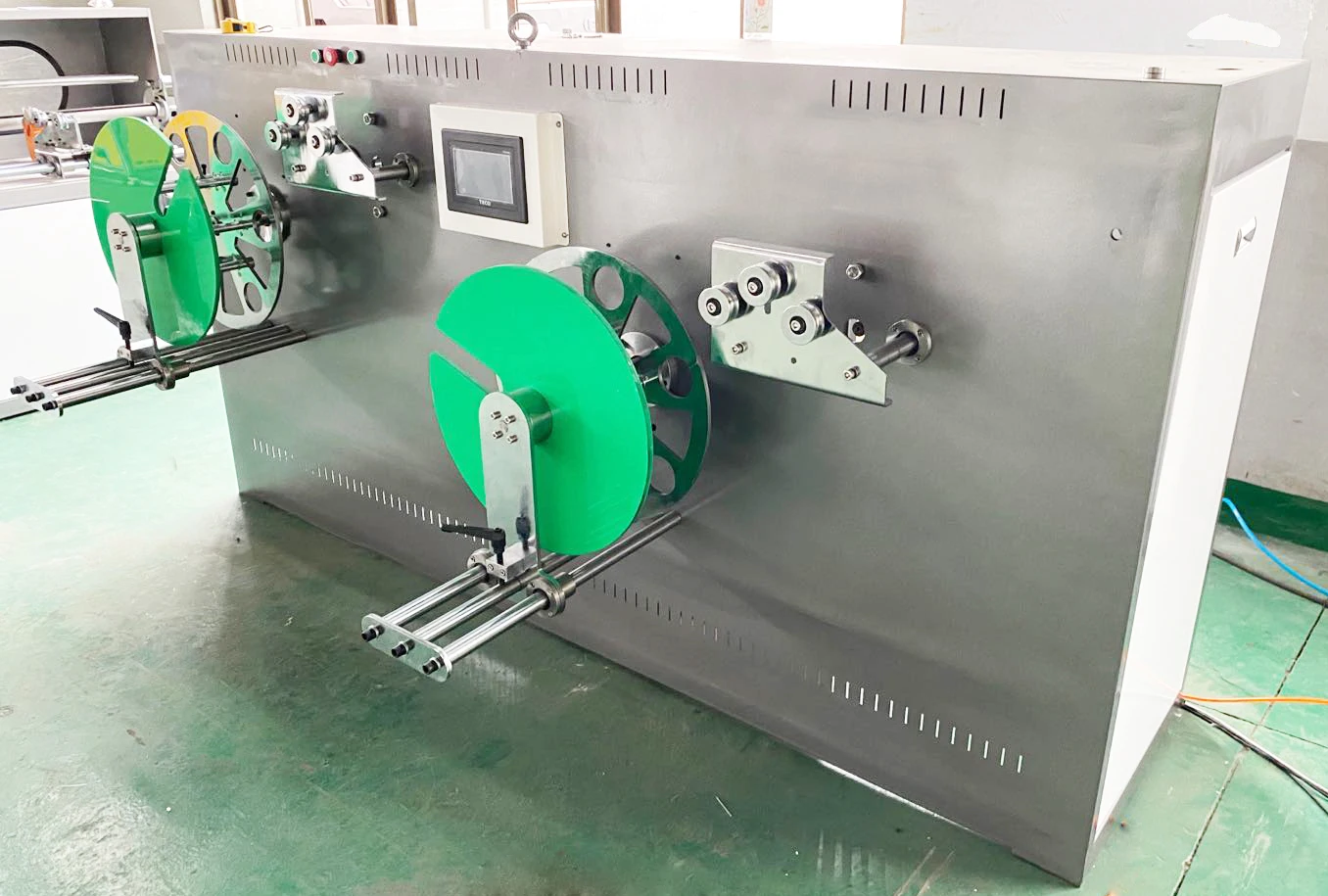

pu pneumatic hose extrusion polyethylene tube pu pipe making machine tpu flexible hose machine

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 1600922659226

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can be processed with the PU pneumatic hose extrusion machine?

The machine is designed to convert various materials, including PVC, PU, and TPU, into high-quality soft pipes.

2. What is the diameter range of pipes produced by this extrusion line?

The die head of the extrusion line can produce pipes with a diameter range of 4–16mm.

3. Can this machine produce double-layer tubes?

Yes, the extrusion line can be modified to produce double-layer tubes upon request.

4. What types of applications can the produced pipes be used for?

The soft pipes can be used in various applications, such as medical catheters, pneumatic tubes, exhaust pipes, and soft drink hoses.

5. How does the temperature control system work?

The high-end temperature control system features an accuracy of ±1-1.5°C, ensuring precise dimensional control during the extrusion process.

6. What is the role of the water cooling tank in the extrusion process?

The water cooling tank helps the pipe rapidly solidify and maintain uniformity during the cooling phase.

7. How is the production process structured?

The production process follows these steps: PVC Pellets → Hopper → Single-Screw Extruder → Mould → Cooling Tank/Vacuum Calibration Machine → Tractor Machine → Cutting/Winding Machine → Stacker.

8. What is the function of the PLC control system?

The PLC control system automates the extrusion process and enables features like automatic stopping of the winding process when the preset length is achieved.

9. Is there an option for automatic winding of pipes?

Yes, an automatic double spool winding machine is available as an optional add-on, controlled by a PLC system for precise winding.

10. What types of finished products can be made with this machine?

The machine can produce soft single-layer tubes made from TPU, PU, and PVC, and double-layer tubes upon request.

11. What are the key components of the extrusion line?

Key components include the main extruder machine, die head, water cooling tank/vacuum tank, tractor machine, cutter/winder, and stacker.

12. How does the tractor machine function in the process?

The tractor machine pulls the tube through the cooling process and leads it to the next stages, such as cutting or winding.

13. What is the driving power range for different models of the machine?

The driving power ranges from 0.75–280 kW, depending on the specific model selected.

14. Can the extrusion line handle high production capacities?

Yes, different models of the machine have varying capacities, with some capable of handling up to 800 kg.

15. What features enhance the stability and efficiency of the machine?

The extrusion line features a high-stable AC motor for energy-efficient production, along with advanced technology components from renowned brands.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading