B21, China Town Mall, Midrand

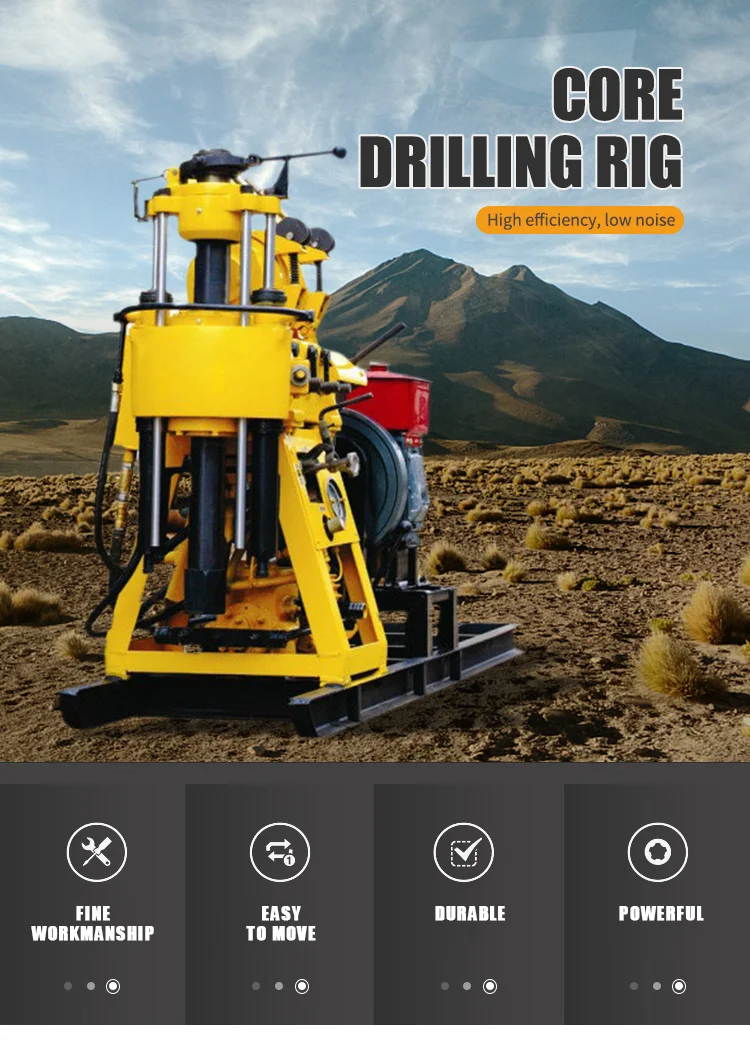

Pneumatic Water Well Drilling Rig 150m Borehole Drilling Machine

- Section : Machinery

- Category : Drilling Rigs

- SKU : 1600080798662

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Pneumatic Water Well Drilling Rig 150m Borehole Drilling Machine used for?

This rig is designed for drilling boreholes up to about 150 m for water wells, geological investigation, core sampling, foundation exploration, levee and subgrade grouting, civil wells, and ground-source (earth temperature) HVAC holes. It can also be configured for coring holes in concrete, road and tall building foundations.

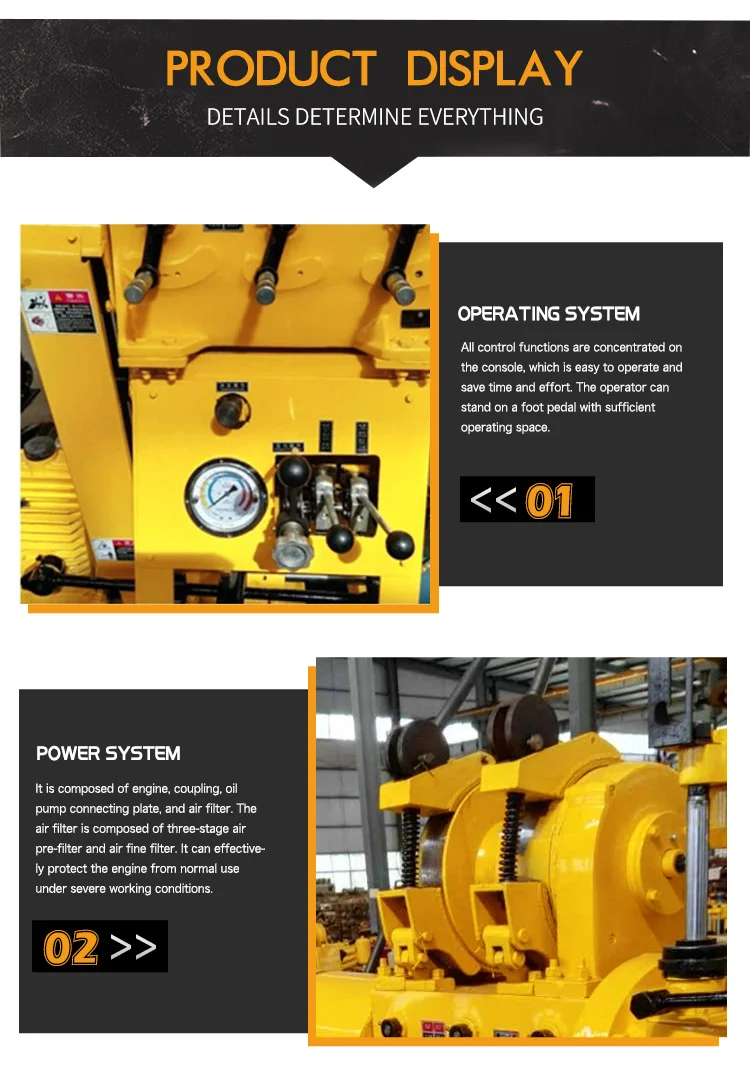

2. Is this machine pneumatic or hydraulic? The description mentions both.

The product name indicates a pneumatic (air-driven) water well rig, while the supplied description references a hydraulic core-drilling configuration. Manufacturers commonly offer pneumatic, hydraulic, or hybrid variants. Please confirm with the seller which power / drive configuration (pneumatic, hydraulic or combined) is supplied for the specific model you are enquiring about.

3. What is the maximum drilling depth and typical borehole diameter range?

Maximum rated drilling depth for this model is approximately 150 meters. Typical borehole diameters depend on tooling and configuration; common ranges for water wells and grouting are roughly 50–300 mm. For diamond coring or specialized applications diameters can differ — confirm the exact diameter capabilities with the supplier.

4. What surface or ground conditions can this rig handle?

The rig is suitable for unconsolidated soils, sands, clays, and many types of sedimentary formations. For harder rock, the rig can be equipped with appropriate tools (DTH hammers, tungsten-carbide or diamond coring bits) but rock drilling performance depends on the chosen drive (pneumatic vs hydraulic) and tooling. Discuss your ground conditions with the vendor to match tooling.

5. What compressed air or power supply is required for the pneumatic version?

Pneumatic versions require a high-capacity air supply. Typical requirements are in the range of 0.6–1.2 MPa (6–12 bar) and airflow of several cubic meters per minute (often 6–20 m³/min), depending on depth and tool. Exact compressor pressure and flow specs vary by model and should be confirmed before purchase.

6. What engine or power options are available?

Rigs are commonly offered with diesel engine drives for field mobility, and some models offer electric motor options for site power availability. Engine power typically varies by model; consult the supplier for the specific engine make, power rating, and optional powertrain configurations.

7. How is the rig transported and how portable is it?

These rigs are typically mounted on small trailers, truck frames, or lightweight crawler/skid platforms for field mobility. Portability depends on the chosen chassis; smaller trailer-mounted units can be towed by a pickup, while larger units require a transport truck or crane for loading.

8. What drilling tools and accessories are included or available?

Available accessories commonly include drill rods, casings, core barrels, DTH hammers, diamond coring bits, mud or airlift pumps, compressors (for pneumatic rigs), winches, stabilizers, and spare parts kits. Confirm the standard package and optional accessories with the supplier.

9. How many operators are needed and what training is required?

Typical operation requires 1–2 trained personnel: a driller and an assistant. Operators should be trained in rig controls, safe rig-up/rig-down procedures, drilling techniques, and PPE use. Many vendors provide operation manuals and can arrange operator training.

10. What core recovery and sample quality can I expect?

When configured for core drilling, the rig can provide continuous core samples suitable for geological logging. Recovery quality depends on tooling (diamond coring vs conventional), drilling fluid/air regime, and formation type. Hydraulic coring often yields better sample control in many conditions; discuss sample requirements with the supplier.

11. What routine maintenance is required?

Routine maintenance includes daily inspection of hoses, fittings, and fasteners; lubrication of moving parts; checking engine/compressor fluids and filters; inspecting drill rods and bits for wear; and periodic hydraulic/air system servicing per the manufacturer's schedule. Keep a stock of critical wear parts to minimize downtime.

12. What safety features should I expect on the rig?

Common safety features include emergency-stop controls, guards around moving parts, pressure relief valves, secure anchoring/stabilizers, clear operator platforms, warning labels, and recommended PPE. Operators must follow local safety regulations and the manufacturer's safety manual.

13. Is spare parts and service support available?

Most reputable suppliers provide spare parts, consumables, and after-sales service or can refer authorized service partners. Ask the vendor about warranty terms, spare parts lead times, and local service availability before purchase.

14. Can the rig be customized for my project (e.g., longer depth, different casing, or coring tools)?

Yes — manufacturers often offer customization such as extended-depth packages, different drill rod/casing systems, specialized coring tools, different powertrains, and auxiliary equipment. Provide your project specs (depth, diameter, ground type, mobility needs) to get a tailored configuration and quote.

15. How do I get pricing, lead time and place an order?

Contact the supplier with project details (required depth, borehole diameter, ground conditions, preferred power option, accessories). The vendor will provide a quotation, delivery lead time, shipping options, and payment terms. Lead time varies by model, customization and current production schedules — ask for a written sales offer.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading