B21, China Town Mall, Midrand

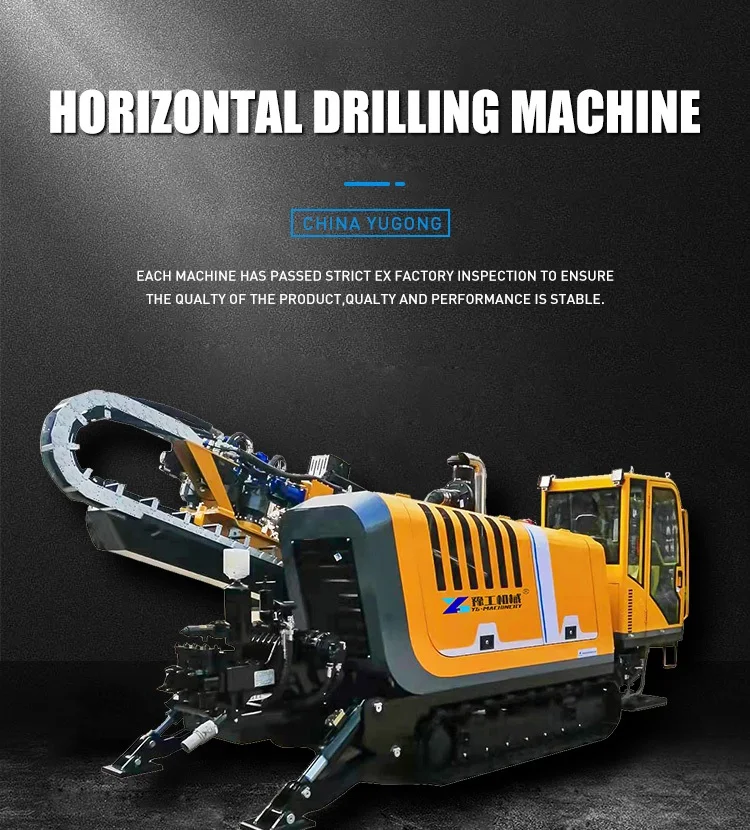

Construction Directional Drilling Machine Horizontal Mining Machine Hdd Machine

- Section : Machinery

- Category : Mining Machinery

- SKU : 1601117254354

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is a horizontal directional drilling machine?

A horizontal directional drilling machine is a specialized equipment used for drilling underground while minimizing surface disruption. It consists of a main drilling rig and a turntable that allows for precise drilling operations.

2. What are the main components of the HDD machine?

The main components of the HDD machine include the main drilling rig, a turntable, drill rods, a control system, and various tools for different drilling operations.

3. What types of projects can this machine be used for?

This machine is ideal for various projects such as installing underground utilities, pipelines, telecommunications cables, and for environmental remediation.

4. How does the turntable function in the drilling process?

The turntable is responsible for rotating the drill rod and adjusting the output speed and torque to meet the requirements of different drilling conditions.

5. What is the maximum drilling depth and diameter for this machine?

The maximum drilling depth and diameter can vary based on the specific model of the HDD machine. It is important to consult the product specifications for precise details.

6. Is the HDD machine suitable for rocky terrain?

Yes, the HDD machine is designed to handle various soil conditions, including rocky terrain, but the effectiveness can depend on the specific drill bits and tools used.

7. What safety features does the horizontal directional drilling machine have?

Safety features typically include emergency stop buttons, protective shields, and advanced monitoring systems to ensure safe operation during drilling.

8. Can this machine be operated by a single person?

While it is possible for a trained operator to manage the machine alone, it is recommended to have a team for efficiency and safety, especially for larger projects.

9. What are the maintenance requirements for the HDD machine?

Regular maintenance includes checking fluid levels, inspecting the drill rods, and ensuring the turntable is functioning properly. It's also important to clean the machine after use.

10. How do I transport the horizontal directional drilling machine?

The HDD machine can typically be transported using a flatbed truck or trailer. Ensure it is securely fastened and complies with local transport regulations.

11. What training is required to operate the HDD machine?

Operators should undergo training on the machine's specific controls, safety protocols, and operational procedures to ensure effective and safe use.

12. Can this machine drill underwater or in wet conditions?

Yes, the HDD machine can be used in wet conditions, but specific precautions and equipment adaptations may be necessary for underwater drilling.

13. What is the average operational speed of the HDD machine?

The operational speed can vary based on the soil conditions and the specific model, but HDD machines generally operate at speeds ranging from a few feet per minute to several hundred feet per hour.

14. What type of drill bits are compatible with the HDD machine?

The HDD machine is compatible with various types of drill bits, including those designed for soft soil, hard rock, and mixed conditions. Selection depends on the specific drilling application.

15. Where can I purchase replacement parts for the HDD machine?

Replacement parts can typically be purchased from the manufacturer or authorized dealers. It’s recommended to consult the machine's manual for specific part numbers.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading