B21, China Town Mall, Midrand

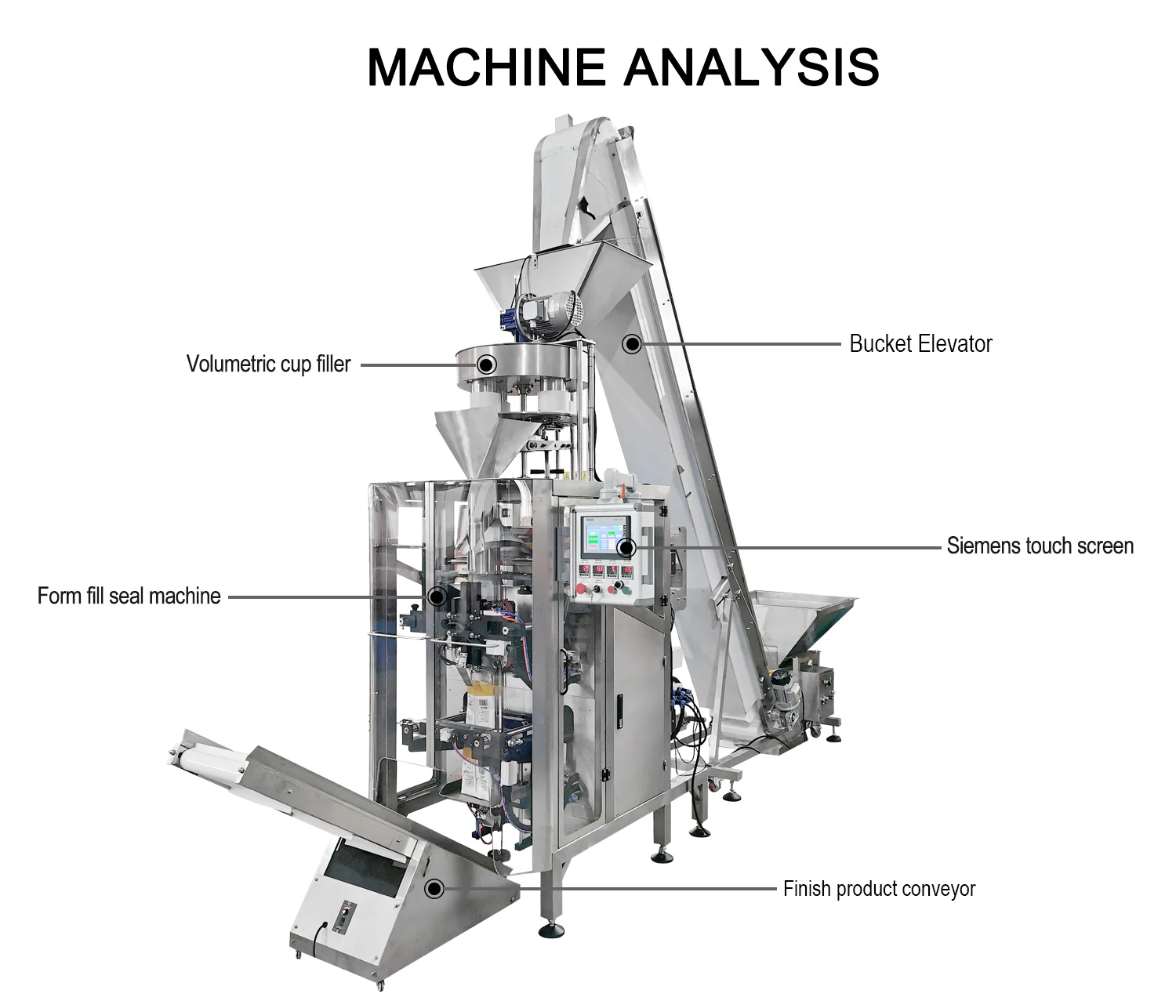

Automatic Back Sealing Bag 1kg 2kg 5kg Ice Cubes Packaging Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600969868291

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What products is the Automatic Back Sealing Bag 1kg 2kg 5kg Ice Cubes Packaging Machine designed to pack?

It is designed primarily for free‑flowing granules such as pasta, oats, cereals, rice, beans, corn, sugar, salt and similar bulk goods. The machine uses a volumetric cup filling system best suited to dry granular and small particulate products.

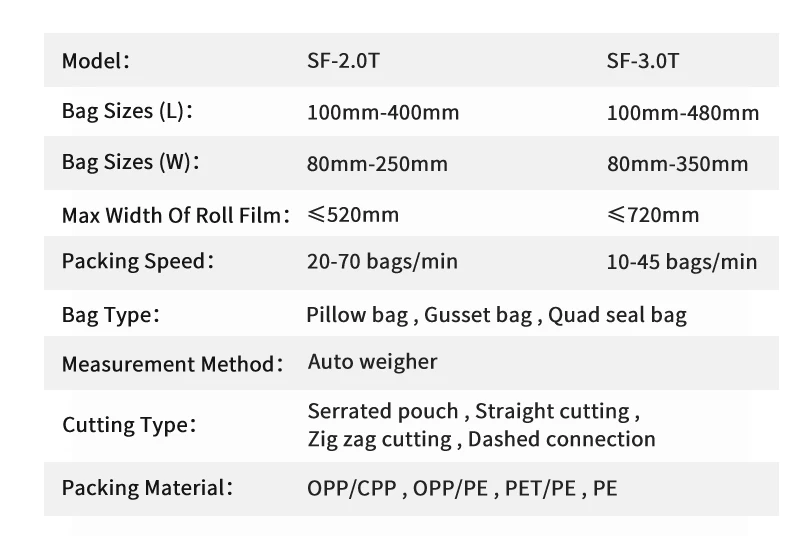

2. Can this machine pack 1kg, 2kg and 5kg bags?

Yes — the vertical FFS design and adjustable volumetric cups allow packing of different weights including 1 kg, 2 kg and 5 kg. Final bag sizes depend on film width, filling cup selection and product bulk density.

3. Is this machine suitable for packaging ice cubes?

The machine is built for dry granules. Packing large, wet ice cubes is not recommended without modification (drainage, refrigeration, anti-stick measures). Crushed or flaked ice might be possible after customization — consult the manufacturer for feasibility and required modifications.

4. What is the machine's production capacity and packing speed?

Typical production capacity ranges from about 25 to 40 bags per minute depending on product characteristics, bag size and film. For larger bag formats (1–5 kg) expect speeds toward the lower end (commonly 25–30 bags/min).

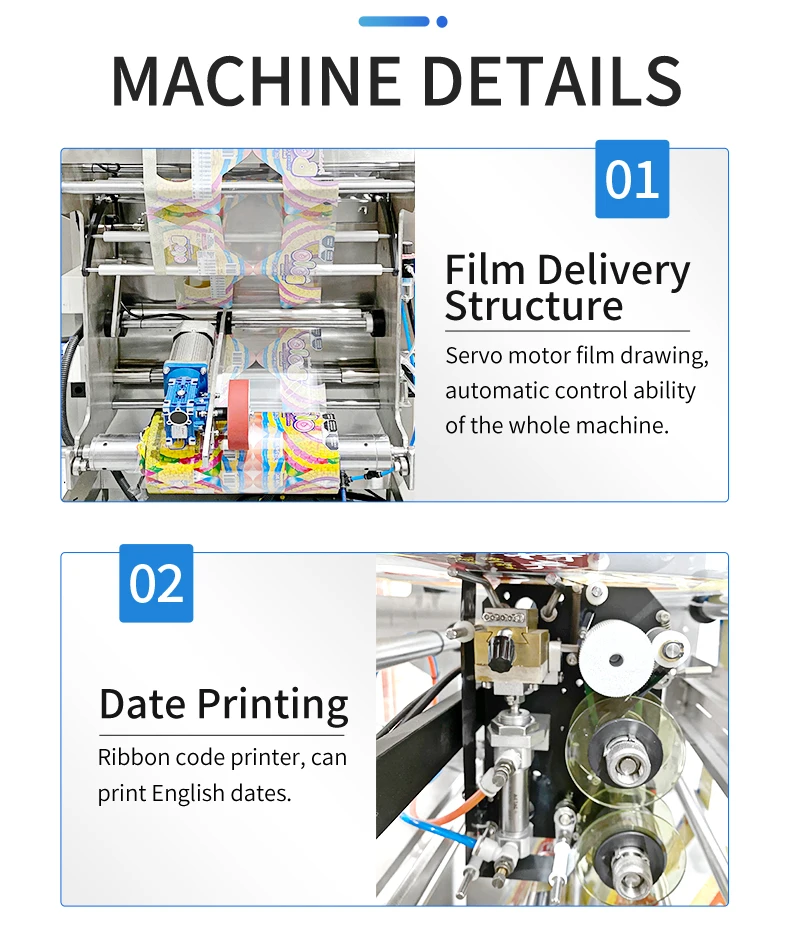

5. What filling system does the machine use and how accurate is it?

It uses an advanced volumetric cup filling system (FFS volumetric cup). This provides consistent, repeatable fills; accuracy depends on product bulk density, particle size and correct calibration. Final accuracy is achieved by selecting the correct cup size and conducting calibration runs.

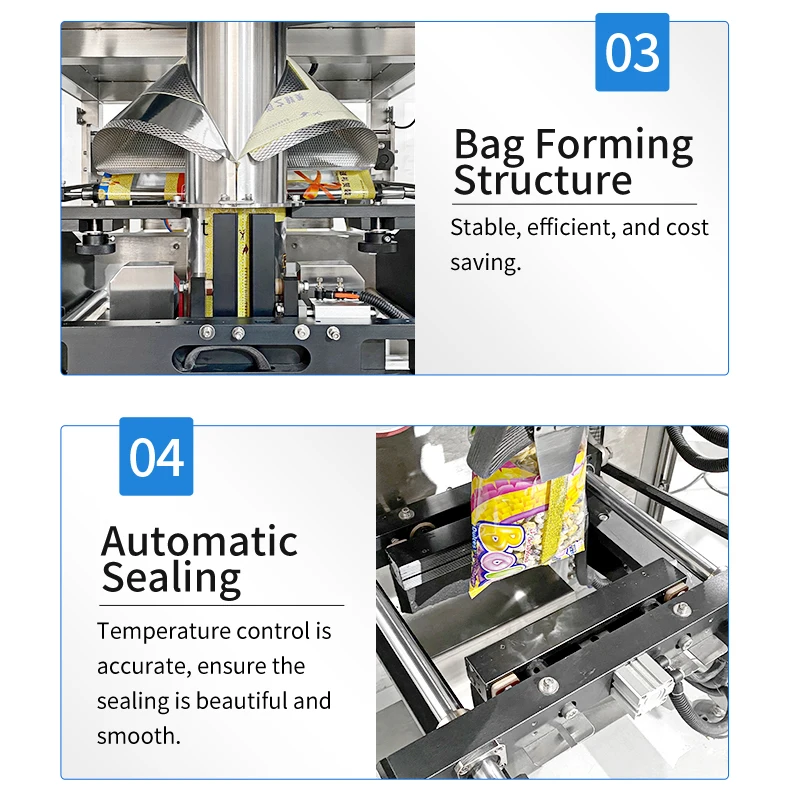

6. What bag types does the machine form and seal?

The machine produces back‑sealing and pillow bags using roll film (laminated films or heat‑seal compatible materials). Sealing is performed vertically as part of the form‑fill‑seal process.

7. What are the machine dimensions, weight and construction material?

Machine dimensions: 4105 x 2457 x 3530 mm (L x W x H). Net weight roughly 800 kg. Contact surfaces and main structure are made from SUS304 stainless steel suitable for food industry environments.

8. What core components and automation does the machine include?

Core components listed include motor(s), pressure vessel, pump, PLC controls, gears, bearings and gearbox. The machine is fully automatic and PLC‑controlled to manage dosing, film forming, sealing and bag cutting.

9. What utilities and site requirements are needed to run the machine?

The machine is electrically driven; specific power voltage and frequency can be configured to customer requirements. Some installations may require compressed air or other utilities for optional accessories—final utility requirements are provided in the technical specification sheet.

10. How long does it take to changeover between bag sizes and products?

Changeover time depends on the extent of adjustments (cup changes, film width, sealing jaw settings). The design supports relatively quick changeovers with straightforward adjustments. Exact times vary; recommended to plan for operator training and have necessary spare cups and tools on hand.

11. What cleaning and maintenance are required?

Because the machine is constructed from SUS304, routine cleaning for food safety is straightforward: daily wiping, removal of product contact parts for deeper cleaning, and regular sanitation as per your HACCP/food safety plan. Periodic maintenance includes lubrication of bearings/gears, inspection and replacement of belts and wear parts, and PLC/electrical checks. Follow the manufacturer’s maintenance schedule for best results.

12. Are spare parts and technical support available?

Yes — core components and wear parts (belts, cups, seals, bearings) are available. The manufacturer/supplier typically offers spare parts, technical support, installation and commissioning services. Confirm lead times and parts availability at time of order.

13. Does the machine come with installation, commissioning and operator training?

Suppliers generally provide installation and commissioning support, as well as operator and maintenance training either on‑site or remotely. Confirm what is included when placing your order.

14. What film materials are compatible and how is the sealing done?

The machine works with heat‑seal compatible roll films (single or laminated films) suitable for vertical form‑fill‑seal processing. Back seal and pillow bag styles are formed and sealed by vertical heat sealing jaws. Film compatibility should be verified for seal strength and barrier requirements of your product.

15. Can this machine be customized and does it have certifications?

Yes — the machine can be customized (cup sizes, infeed systems, dust control, dosing options, special features for sensitive products). Certifications (e.g., CE) and full compliance documentation can be provided depending on order and destination market — discuss certification needs with the supplier before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading