B21, China Town Mall, Midrand

DZ-600 Easy Operate Date Palm Vacuum Packaging Machines

- Section : Machinery

- Category : Vacuum Packing Machines

- SKU : 1600574220976

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the DZ-600 Easy Operate Date Palm Vacuum Packaging Machine?

The DZ-600 is an automatic double-chamber vacuum packaging machine designed for efficient vacuum packing of date palms and other products. It performs vacuum extraction, (optional) gas flushing, sealing and exhaust automatically and features a 304 stainless steel chamber and structure for food-safe operation.

2. What models are available and how do they differ?

Available models include DZ-600, DZ-500 and DZ-400. They differ mainly by chamber size, seal length, pumping speed, pump quantity, overall machine dimensions and weight. DZ-600 has the largest chamber (600×430×120 mm) and two 40 m³/h pumps; DZ-500 has a 500×430×120 mm chamber and two 40 m³/h pumps; DZ-400 has a 400×400×120 mm chamber and one 20 m³/h pump.

3. What are the key technical specifications?

Highlights: DZ-600 chamber 600×430×120 mm, two seal bars 600×10 mm, machine size 1450×600×1030 mm, power 1.5 kW, pumping speed 40 m³/h (x2 pumps), weight 210 kg. DZ-500: chamber 500×430×120 mm, two 500×10 mm seals, 1270×600×1020 mm, 1.5 kW, 40 m³/h (x2), weight 170 kg. DZ-400: chamber 400×400×120 mm, two 400×10 mm seals, 1070×540×970 mm, 0.9 kW, 20 m³/h (x1), weight 120 kg. Voltage options: 220V/380V, 50–60 Hz (customizable).

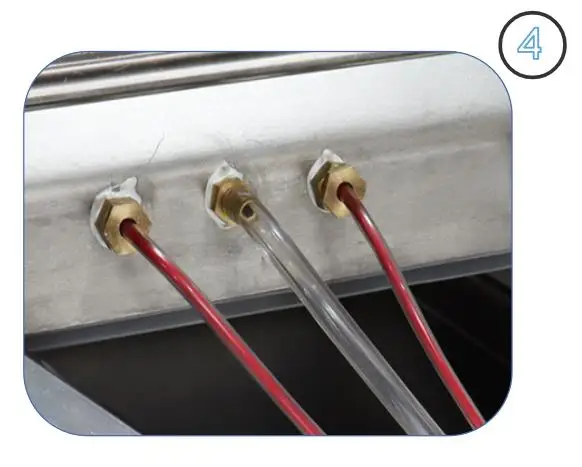

4. Can this machine perform gas flushing (MAP)?

Yes. Gas flushing (modified atmosphere packing) is available as an optional feature and can be integrated so the machine runs vacuum extraction, gas flush, sealing and exhaust automatically.

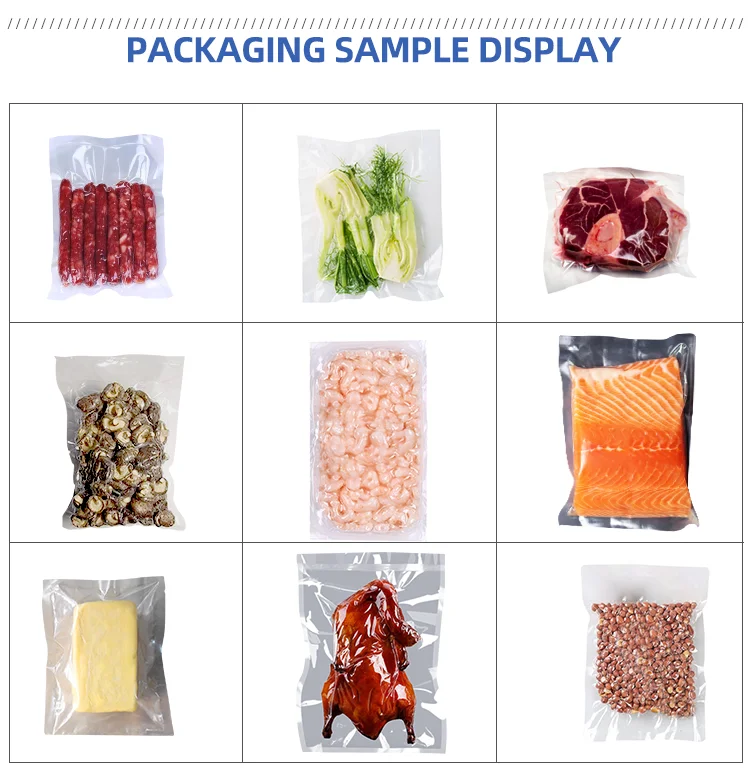

5. Is the machine suitable for packing date palms and other food products?

Yes. The 304 stainless steel chamber and structure are food-grade and the vacuum process prevents oxidation, mold, insect infestation and moisture, helping to extend the shelf life of dates and other perishable foods.

6. What types of packaging materials are compatible?

The machine is compatible with standard heat-sealable vacuum bags and pouches suitable for vacuum packaging. For trays or specialized films check dimensions against chamber size and sealing bar length.

7. How fast is the DZ series? What is the work efficiency?

Work efficiency is typically 1–4 cycles per minute depending on model, bag size, vacuum level and operator workflow. Larger chambers and stronger pumps usually allow faster processing of larger or bulk packs.

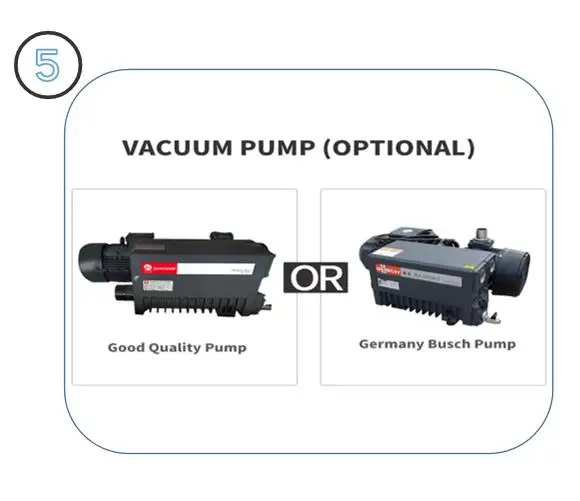

8. What vacuum pump and electrical components are used?

The machines come with industrial-strength vacuum pumps (models vary). Options include single or dual pumps (20 m³/h or 40 m³/h per pump). They use high-quality electrical components, a pure copper transformer and neat internal wiring. Specific pump brands and configurations can be customized on request.

9. Can I customize voltage, plug type or other features for my region?

Yes. Voltage and plug type (220V/380V, 50–60 Hz) and many other options—such as gas flushing, deep vacuum chamber, automatic swing lid, control panel layout and full 304 SUS construction—can be customized to your requirements.

10. Is OEM/ODM available?

Yes. The manufacturer offers OEM and ODM services to provide tailored solutions including branded panels, customized chamber depth, optional equipment and modified controls.

11. What regular maintenance is required?

Regular tasks include cleaning the stainless chamber and sealing bars, checking and replacing the lid gasket if worn, inspecting seals, and servicing the vacuum pump (including oil changes) according to usage—commonly every 3–6 months depending on workload. Follow the user manual for specific intervals and procedures.

12. How do I operate the machine? Is it easy to use?

The DZ series features an intelligent control panel for easy operation. Typical steps are place product in bag, position bag in chamber, close lid, start the automatic program (vacuum, optional gas flush, sealing, exhaust). Training is recommended for optimal settings and safe operation.

13. What after-sales support and spare parts are available?

Spare parts (gaskets, sealing wires, pump parts, electrical components) are available from the manufacturer or distributor. For warranty terms, spare parts lead times and local service options, contact the supplier directly.

14. What safety measures should I be aware of?

Follow the operator manual and local electrical safety codes. Ensure correct voltage, proper grounding and routine inspections. If you choose options like an automatic swing lid, review any additional safety interlocks or procedures provided by the manufacturer.

15. How can I get pricing, lead time and shipping information?

Contact the supplier or sales representative with your desired model (DZ-600/DZ-500/DZ-400), custom options (voltage, gas flush, pump configuration, OEM/ODM requirements) and delivery destination. They will provide a quote, estimated production lead time and shipping arrangements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading