B21, China Town Mall, Midrand

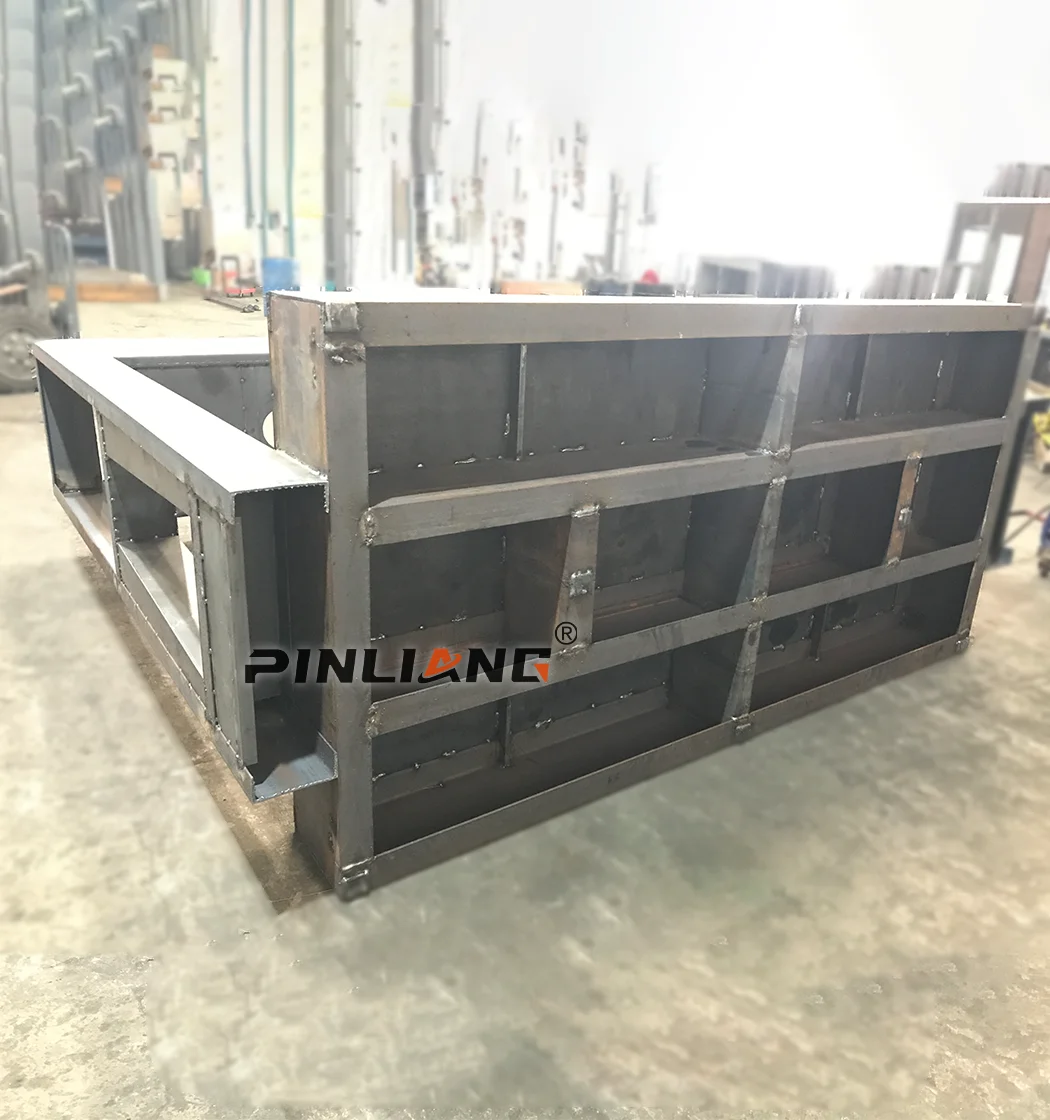

60 Ton Woodworking Hydraulic Cold Press Machine For Plywood And Door Making

- Section : Machinery

- Category : Woodworking Machinery

- SKU : 1601043306008

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum pressing force of the machine?

The machine provides a maximum pressure of 0–60 tons (0–60T).

2. What are the working table size and plate spacing options?

Table size is 1250 × 2500 mm. Plate (working table) spacing options are 1000 mm or 1300 mm.

3. What are the overall dimensions and weight of the machine?

Overall dimensions are 2950 × 1250 × 2900 mm (L × W × H) and the machine weight is approximately 1900 kg.

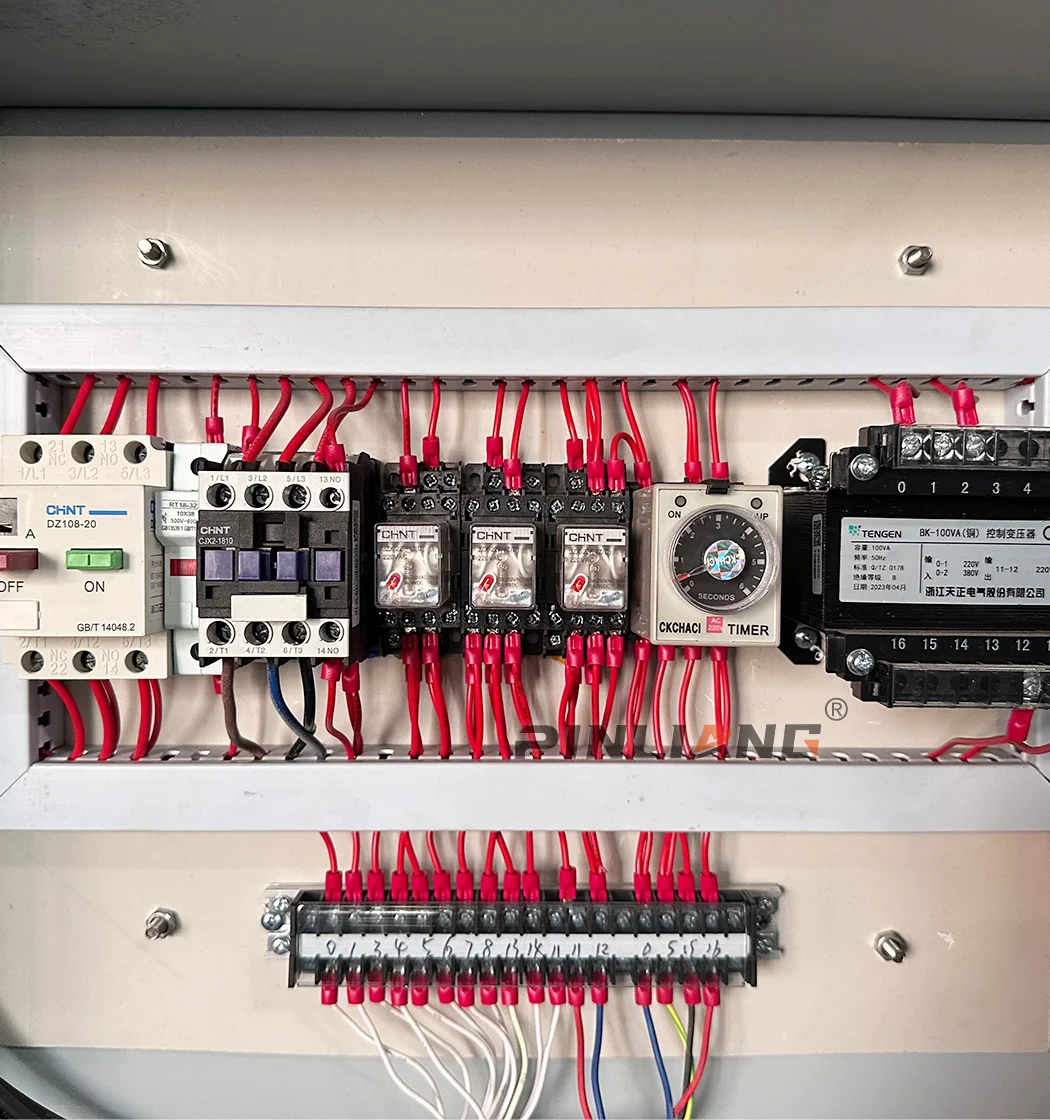

4. What are the power and electrical requirements?

Installed power is 5.5 kW. Standard electrical specification is 380 V, 50 Hz, 3-phase.

5. What hydraulic cylinder specifications does the machine use?

The machine uses two hydraulic cylinders with specification 85 × 125 (85*125*2pcs).

6. What is the flatness tolerance of the working table?

Overall working table flatness is ±0.2 mm.

7. Which materials and applications is this press suitable for?

This cold press is designed for plywood production and wooden door making. It can also be used for laminating, veneering and other wood-based panel pressing tasks—contact us for confirmation on other materials.

8. Is customization available if the listed parameters don't meet my needs?

Yes. If these parameters don't meet your needs, we offer other models and can provide customized services—please contact us with your required specifications.

9. Does the machine include an electrical control panel and what components are used?

Yes. The machine includes a clear and easy-to-use control panel. It uses well-known brand electrical components for reliability and durability.

10. What safety features are included?

The machine includes standard operational controls via the control panel. Specific safety features (e.g., emergency stop, safety guards, interlocks) depend on model/configuration—please request detailed safety specifications for the unit you plan to purchase.

11. What is the expected production rate or cycle time?

Production rate depends on board size, pressing time, adhesive curing requirements and operator workflow. Cycle time is not fixed in the spec; contact us with your process parameters and board dimensions for an estimated output rate.

12. What are the installation requirements (foundation, floor load, space)?

You will need sufficient workshop floor space to accommodate the machine dimensions (2950 × 1250 × 2900 mm) plus working clearance. A flat, level concrete floor with load-bearing capacity for ~1900 kg plus parts and operators is recommended. For precise foundation and anchoring requirements, request the installation guide for the chosen model.

13. What maintenance is required and what hydraulic oil should be used?

Regular maintenance includes checking hydraulic oil level and cleanliness, inspecting seals and hoses, greasing relevant points, and periodic electrical inspections. Recommended hydraulic oil grade and maintenance intervals depend on operating conditions—please consult the machine manual or contact support for the recommended oil type and service schedule.

14. Is there warranty, spare parts availability and after-sales support?

The manufacturer provides after-sales support and spare parts. Warranty terms and spare parts availability vary by supplier and model—please ask your sales representative for specific warranty duration, included coverage and spare parts lead times.

15. What are typical lead times, shipping options and are machines kept in stock?

Some machines are held in partial inventory at the warehouse for faster delivery, while others are produced to order. Lead times depend on stock status, customization and shipping destination. Contact sales with your order details and destination for accurate lead time and shipping options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading