B21, China Town Mall, Midrand

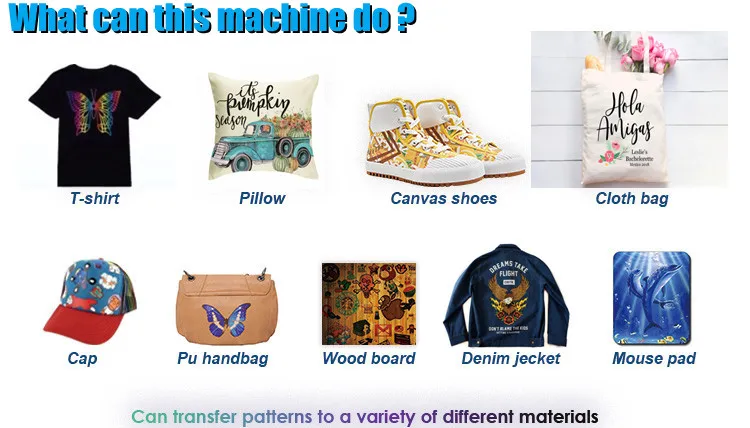

24inch dual XP600 dtf printer A1 60CM dtf printers with dryer machine and consumables

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 1600493469339

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum printing width of the 24inch dual XP600 DTF printer?

The maximum printing width of the 24inch dual XP600 DTF printer is 24 inches, allowing for wide format printing suitable for various fabric types.

2. Does this printer require pre-treatment of fabrics?

No, one of the strongest selling points of DTF printing technology is that it does not require pre-treatment of fabrics.

3. What types of fabrics can I print on using this printer?

You can print on almost every type of fabric, including cotton, polyester, and blends, making it versatile for various applications.

4. What is included in the package with the DTF printer?

The package includes the 24inch dual XP600 DTF printer, a dryer machine, and consumables necessary for the printing process.

5. How do I perform the powder application step in DTF printing?

To apply the hot-melt powder, ensure that the printed film is wet, then evenly spread the powder over the image using a light rocking motion or an automated shaker for uniform coverage.

6. What temperature and time are required for melting the powder?

The powder should be melted at a temperature of 160 to 170 degrees Celsius for approximately 2 to 5 minutes, either in a curing oven or with a heat press.

7. What is the purpose of pre-pressing the fabric?

Pre-pressing the fabric helps to flatten it and remove any humidity, which ensures a proper transfer of the image from the film to the fabric.

8. Can I transfer the design immediately after pressing?

No, it's important to let the fabric and the attached film cool down to room temperature before peeling off the film to ensure strong adhesion.

9. Is post-pressing necessary for the final product?

While post-pressing is optional, it is highly recommended for improving wash and rub fastness of the printed design.

10. What are the color capabilities of this printer?

The dual head design of the XP600 allows for sharper and more vibrant colors, enhancing the quality of prints significantly.

11. What is the recommended gap between the heat press and the film during melting?

A gap of around 4 to 7 mm should be maintained between the heat press top plate and the film to ensure proper melting of the powder without direct contact.

12. How long does the entire DTF printing process take?

The total time can vary, but each step typically takes a few seconds to a few minutes depending on the specific task, with the transfer step taking around 15 to 20 seconds.

13. What kind of maintenance does the printer require?

Regular maintenance includes cleaning the print heads, ensuring the printer is free of dust, and checking for any software updates to keep the printer functioning optimally.

14. Can I print images with multiple colors?

Yes, the DTF printer can handle multi-colored images, as it prints a white base first followed by the colored image, ensuring vibrant results.

15. Where can I find additional resources or support for using the DTF printer?

Additional resources, including user manuals and support forums, can typically be found on the manufacturer's website or by contacting customer support directly.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading