B21, China Town Mall, Midrand

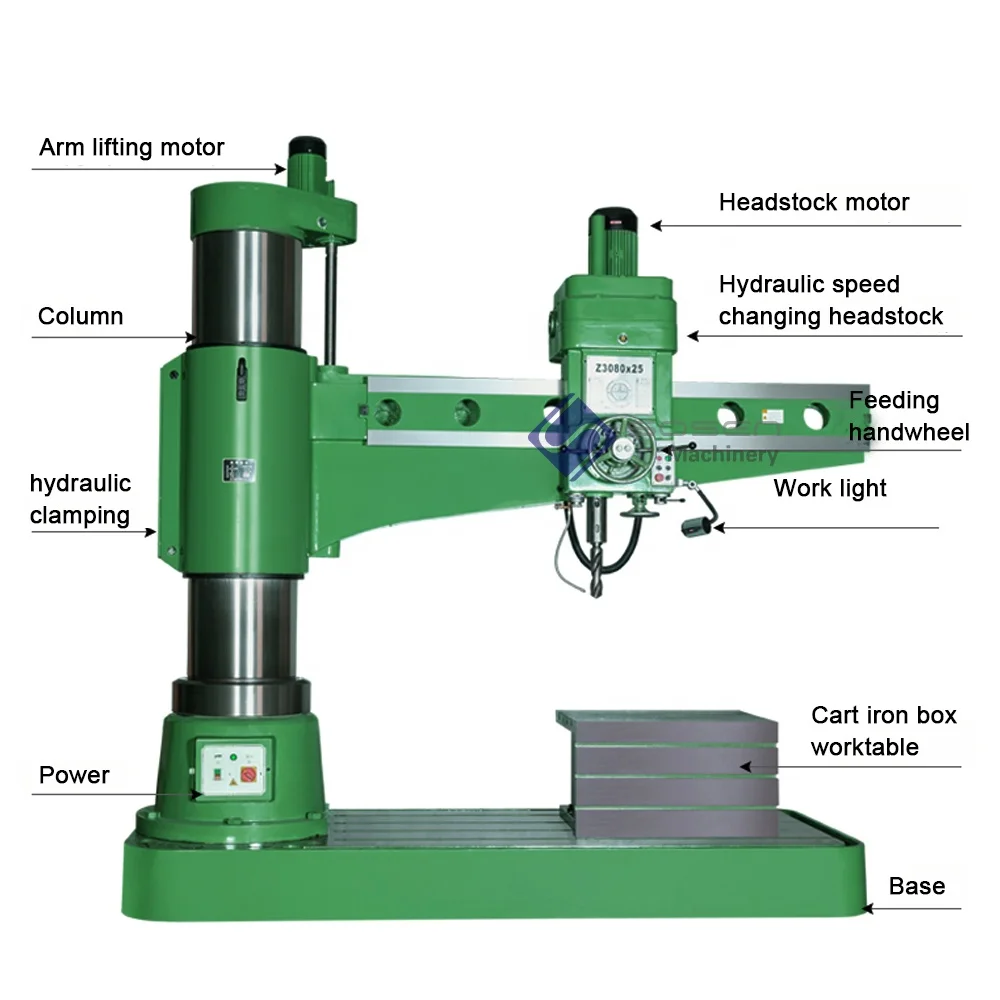

Z3080x25 Metal Radial Drilling Machine for Big Holes

- Section : Machinery

- Category : Industrial Machinery

- SKU : 62275131135

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 Jun, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Z3080x25 Metal Radial Drilling Machine for Big Holes?

A heavy-duty radial drilling machine designed for drilling large-diameter holes in metal workpieces. It features a pivoting radial arm and movable drill head to position the spindle over large or awkward workpieces.

2. What size holes can the Z3080x25 drill?

The machine is engineered for large-diameter drilling. Exact maximum drilling capacity depends on material, tooling and configuration; the model number (Z3080x25) typically denotes a large-capacity radial drill — please consult the datasheet or factory for the guaranteed maximum hole diameter under your operating conditions.

3. What does the model designation "x25" indicate?

"x25" normally refers to the nominal radial arm reach (e.g., 2500 mm) or a specified working range for that model. Confirm the exact arm length and travel in the product datasheet or with the supplier.

4. Which materials can be machined with this radial drill?

It is suitable for a wide range of metals including carbon steel, alloy steel, stainless steel, cast iron, aluminum and other non-ferrous metals. Cutting speed, feed and tooling should be selected based on the specific material.

5. What spindle speed and feed control options are available?

The Z3080x25 is typically supplied with a multi-speed gearbox (mechanical or electrical speed selection) and power/manual feed for the spindle. Specific speed ranges and feed increments depend on the chosen configuration—refer to the technical specifications for exact values.

6. What tooling and spindle taper does it use?

Commonly offered with standard spindles that accept Morse tapers or industry-standard toolholders and chucks. The exact spindle taper and maximum chuck size will be listed in the machine’s specification sheet or can be customized on request.

7. What are the common accessories and options available?

Typical options include power-operated chuck, coolant system, digital readout (DRO), variable-frequency drive (VFD), work-holding fixtures, rotary tables, indexers and special chucks or adaptors for large tooling.

8. What are the electrical and power requirements?

Standard industrial power is three-phase (for example 380–415 V, 50/60 Hz), but exact motor ratings and electrical requirements depend on configuration and market. Confirm required supply and motor power with the supplier before installation.

9. What foundation and installation requirements are needed?

A level, rigid foundation or concrete plinth is usually required; anchor bolts for securing the base; adequate floor space for arm swing and workpiece handling; and access for lifting heavy workpieces. The supplier provides installation instructions and can offer site supervision if needed.

10. How do I maintain the Z3080x25?

Regular maintenance includes lubrication of bearings and ways, checking and topping gearbox oil, keeping the machine clean from chips and coolant residue, checking belt and coupling condition, and periodic inspection of spindle runout and alignment. Follow the manufacturer’s maintenance schedule.

11. What safety features are included?

Standard safety features typically include emergency stop, mechanical or transparent chip guards, safety interlocks for certain options, electrical overload protection and clearly marked controls. Additional guarding or enclosures can be supplied to meet site-specific safety requirements.

12. What accuracy and repeatability can I expect?

Accuracy depends on machine configuration, fixturing, tooling and operator setup. The machine is built for industrial production with stable geometry for consistent hole location; specific tolerances and repeatability figures are provided in the technical data sheet or can be validated during factory acceptance testing (FAT).

13. What warranty and spare parts support are available?

Warranty terms vary by supplier—commonly a 12-month limited manufacturer warranty. Spare parts, consumables and after-sales support are typically available from the manufacturer or authorized dealers; discuss local stocking and lead times when ordering.

14. How long is the lead time and how is the machine shipped?

Lead time depends on configuration and order backlog; typical delivery lead times range from a few weeks to a few months. Machines are usually tested, partly disassembled for transport, and packed in wooden crates or on pallets. Confirm exact lead time and shipping method with sales.

15. How do I request a quote or get more technical information?

Contact the supplier or manufacturer with your application details (material, maximum hole diameter, workpiece size, preferred accessories and electrical supply). Request the full technical datasheet, dimensional drawings, and optional factory acceptance/test reports to ensure the machine meets your needs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading