B21, China Town Mall, Midrand

Vibration Needle Power Concrete Vibrators

- Section : Electrical & Tools

- Category : Power Concrete Vibrators

- SKU : 1601232988374

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 12 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary use of the Vibration Needle Power Concrete Vibrator?

The primary use of the Vibration Needle Power Concrete Vibrator is to enhance the concrete compaction process, ensuring a smooth and durable finish on concrete surfaces.

2. What are the key features of the Vibrating Table?

Key features include high operating efficiency, electric drive mode, a vibration frequency of 200Hz, a vibrating amplitude of 0.9mm, a flexible shaft length ranging from 1m to 10m, and voltage options of 220v and 380v.

3. How does the electric drive mode benefit the user?

The electric drive mode provides reliable performance and efficiency, reducing the need for frequent maintenance and ensuring consistent operation.

4. What is the weight and dimension of the Vibrating Table?

The Vibrating Table weighs 25kg and has dimensions of 265x265x190mm, making it compact and easy to transport.

5. What warranty is provided with the Vibrating Table?

The Vibrating Table comes with a 1-year warranty, offering peace of mind and reliable after-sales support.

6. Can the Vibrating Table be used for various project sizes?

Yes, the Vibrating Table is designed with a flexible shaft that can be adjusted from 1m to 10m, making it versatile for different project sizes.

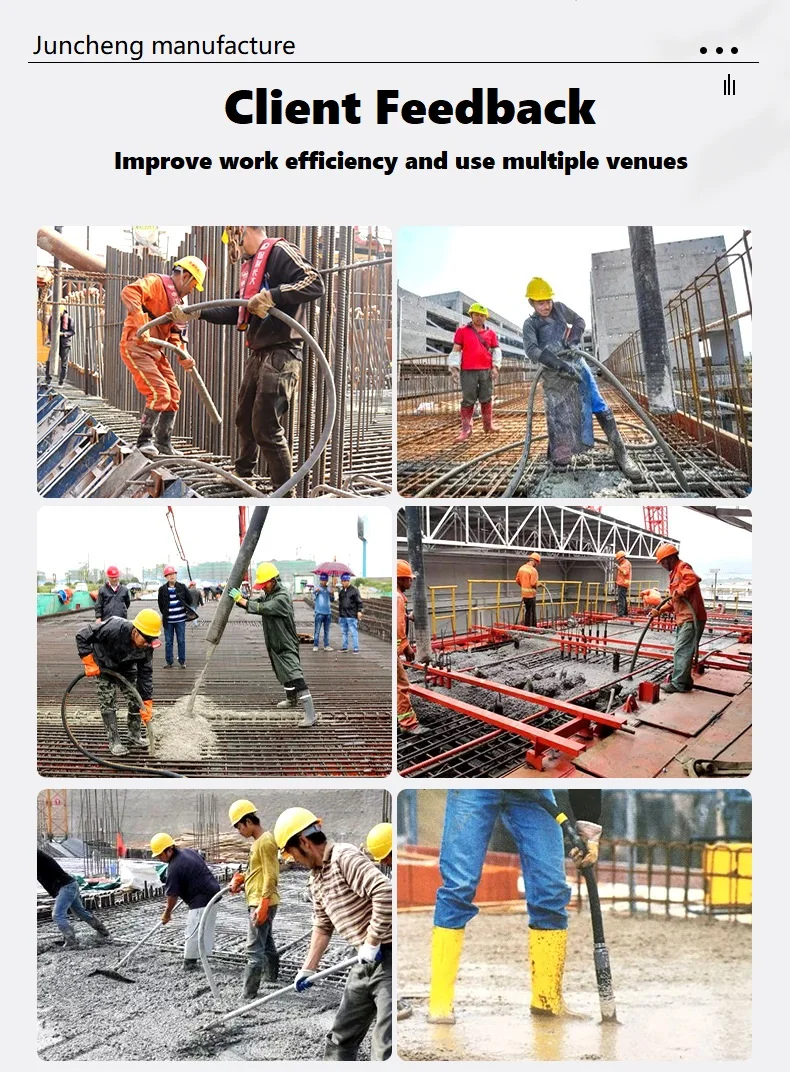

7. What industries can benefit from using the Vibrating Table?

The Vibrating Table is ideal for use in building material shops and construction works, helping to ensure superior concrete finishes.

8. What precautions should be taken while using the vibrator?

Precautions include determining the correct insertion depth, monitoring vibration time based on concrete type, using appropriate vibration methods, and ensuring safe operation with protective equipment.

9. How can I maintain the Vibration Needle Power Concrete Vibrator?

Regular maintenance includes cleaning the vibrator after use, conducting inspections for damage, lubricating moving parts, and storing it in a dry, ventilated area.

10. What is the frequency and amplitude of the vibration?

The Vibrating Table operates at a frequency of 200Hz and has a vibrating amplitude of 0.9mm, ensuring effective concrete compaction.

11. Is the Vibrating Table easy to transport?

Yes, with its compact design and moderate weight, the Vibrating Table is easy to transport and operate in various construction environments.

12. How does the concrete vibrator improve the quality of concrete?

The concrete vibrator increases density, reduces voids, improves uniformity, and lowers the temperature of the concrete, resulting in a stronger and more durable finish.

13. What are the voltage options for the Vibrating Table?

The Vibrating Table is available in both 220v and 380v options, allowing it to meet different project power requirements.

14. What type of maintenance do the core components require?

Core components, such as the engine, require regular inspections and lubrication to ensure long-term performance and reliability.

15. Can I use the Vibrating Table for high-performance concrete?

Yes, the Vibrating Table is suitable for high-performance concrete applications, ensuring effective compaction and quality results.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals