B21, China Town Mall, Midrand

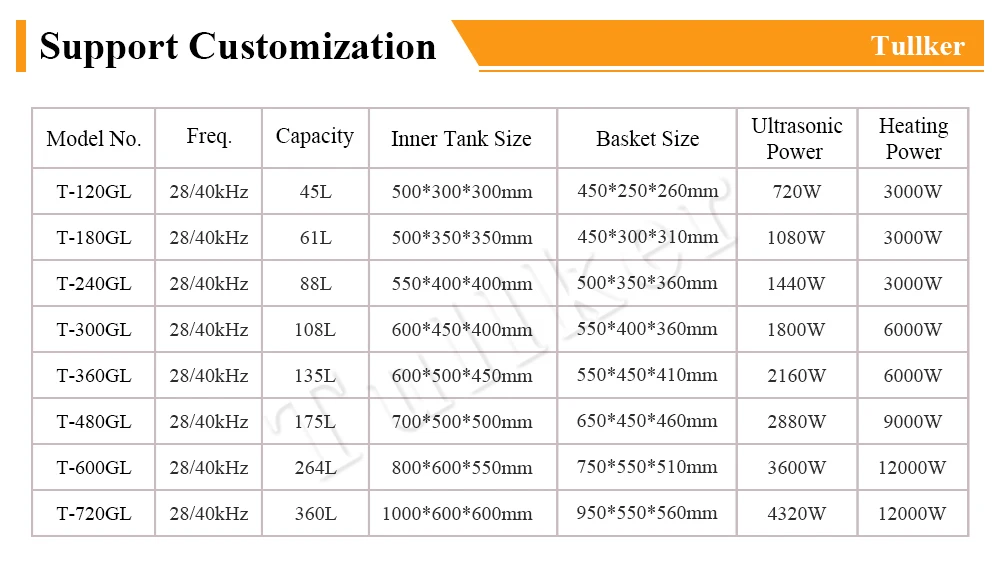

Tullker 108 L Filter Equipment Industrial Ultrasonic Cleaner

- Section : Machinery

- Category : Industrial Ultrasonic Cleaners

- SKU : 1600218429225

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the capacity of the Tullker 108 L Ultrasonic Cleaner?

The cleaner has a tank capacity of 108 liters, suitable for large industrial parts such as engine blocks, molds, DPFs and injectors.

2. What materials and parts can this ultrasonic cleaner handle?

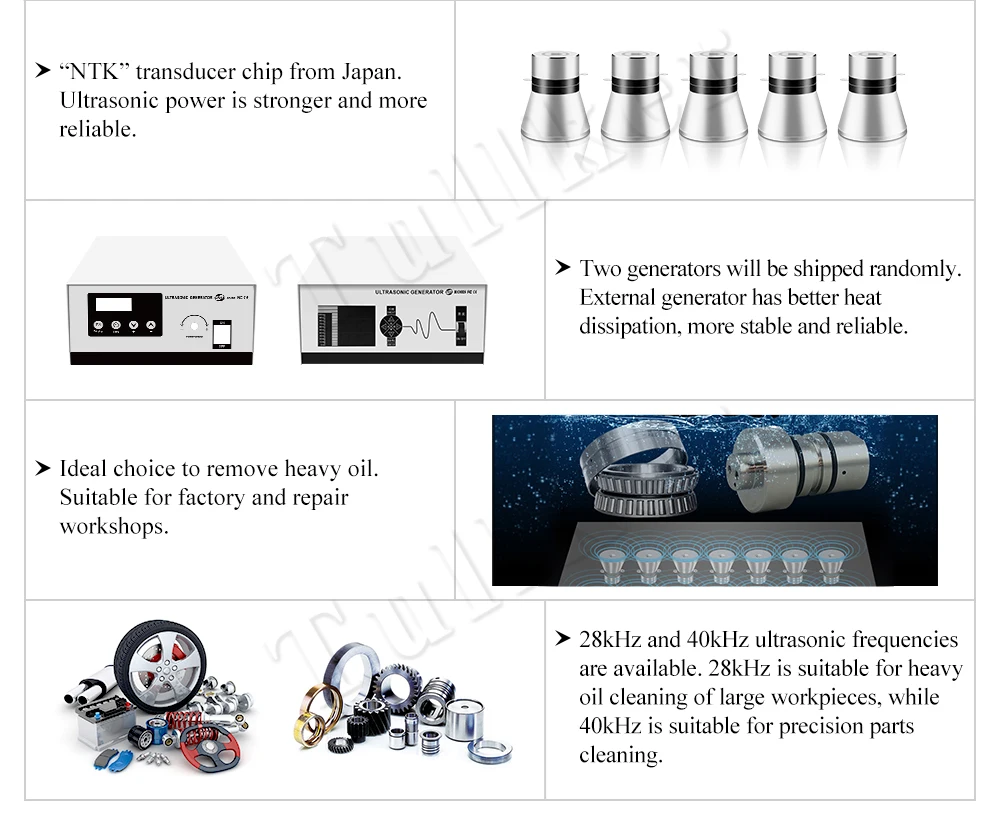

It is designed for metal parts, molds, diesel parts, DPFs, oil/rust-affected components, engine blocks, cylinders, injectors and similar industrial components.

3. How is the machine controlled and operated?

It uses a digital display with MCU-SWEEP automatic frequency tracking generator. Controls include adjustable time, temperature, ultrasonic power and a one‑button degassing function for easy operation.

4. What temperature range does the heater support?

The built-in heater is adjustable from 20°C up to 100°C to accelerate cleaning and improve results for stubborn contaminants.

5. Can I adjust ultrasonic power and cleaning time?

Yes. Ultrasonic power is continuously adjustable from 0–100%, and cleaning time can be set in minutes or hours to match different cleaning requirements.

6. What type of transducers does the unit use and what are the benefits?

It uses high-Q ultrasonic transducers with high-strength adhesive bonding. This provides higher energy transfer efficiency, more homogeneous ultrasonic fields and longer service life.

7. Is there protection against running the unit dry?

Yes. The machine has a liquid level protection feature and will issue an abnormal alarm if the ultrasonic system attempts to operate without sufficient liquid.

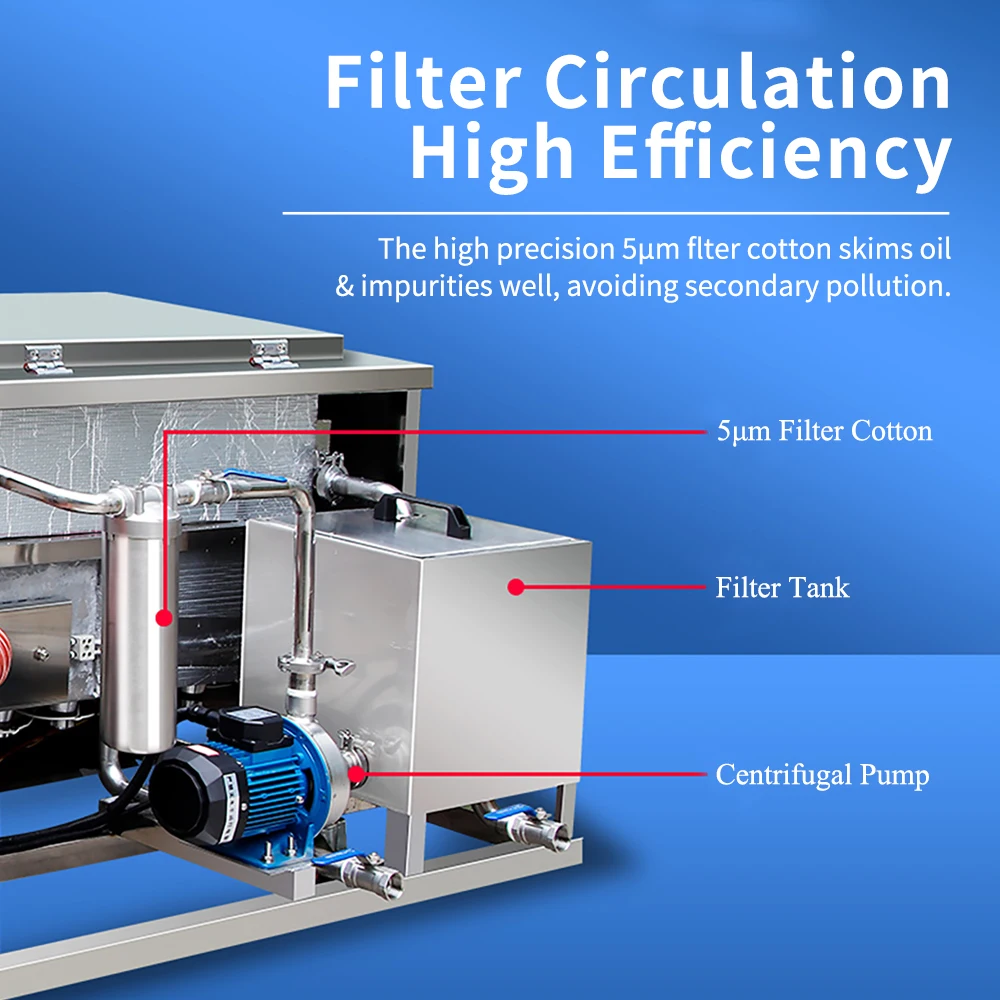

8. Does the cleaner include filtration or basket systems?

The standard offering includes a 304 stainless steel washing basket and a mute cover. Additional filtration and circulation systems or an automatic basket lifting system can be added as optional accessories.

9. What safety and quality certifications does the product have?

The unit is manufactured under strict processes, has passed a 2500V high-voltage test, and is certified by CE, RoHS and FCC according to the product description.

10. How effective is the degassing feature and how do I use it?

The one-button degassing (MCU-SWEEP drive) quickly removes dissolved air from the water to strengthen cavitation. Use the degas button before cleaning to improve ultrasonic penetration and results.

11. How do I maintain and clean the ultrasonic tank?

Regularly drain and rinse the tank, remove residue and inspect welds and transducer mounting. Replace cleaning solution as needed, avoid abrasive scrubbing of the tank surface, and follow the manufacturer maintenance schedule in the manual.

12. What kind of maintenance do the transducers require?

Transducers are high-durability units but should be checked periodically for secure mounting and signs of damage or adhesive failure. Do not operate the unit dry and avoid mechanical shocks to the tank to prolong transducer life.

13. Are there noise reduction features?

Yes. The machine comes with a mute (sound-reduction) cover to reduce operational noise levels during cleaning cycles.

14. Can I use custom cleaning solutions and what should I be careful about?

You can use various ultrasonic-compatible cleaning solutions tailored to contaminants (degreasers, alkaline cleaners, acid dips where appropriate). Always follow manufacturer guidance for concentration, temperature limits, compatibility with the tank material (SUS304) and safety precautions. Avoid flammable or strongly reactive chemicals unless specified as safe by the manufacturer.

15. What warranty and after-sales support are available?

Warranty terms and after-sales support vary by supplier and region. Refer to the product documentation or contact the seller/manufacturer for details on warranty length, spare parts and service options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading