B21, China Town Mall, Midrand

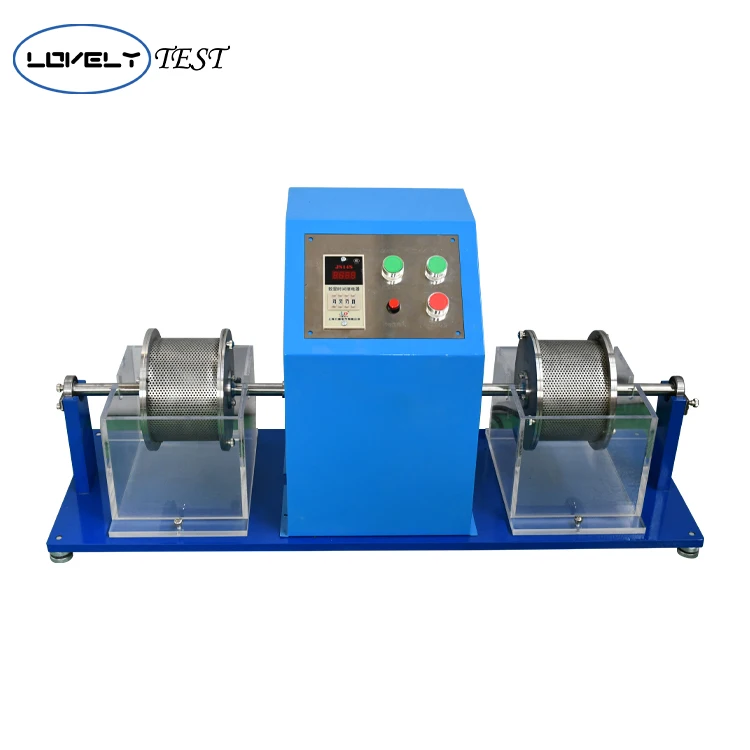

Slake Durability Apparatus for Rock/Civil Engineer Test

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1600970223549

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 26 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary use of the Slake Durability Apparatus?

The Slake Durability Apparatus is primarily used to test the durability of rocks, gravel, and slag, assessing their stability and performance under various environmental conditions.

2. What is the operating speed of the apparatus?

The apparatus operates at a constant speed of 20 revolutions per minute (RPM) for standardized testing conditions.

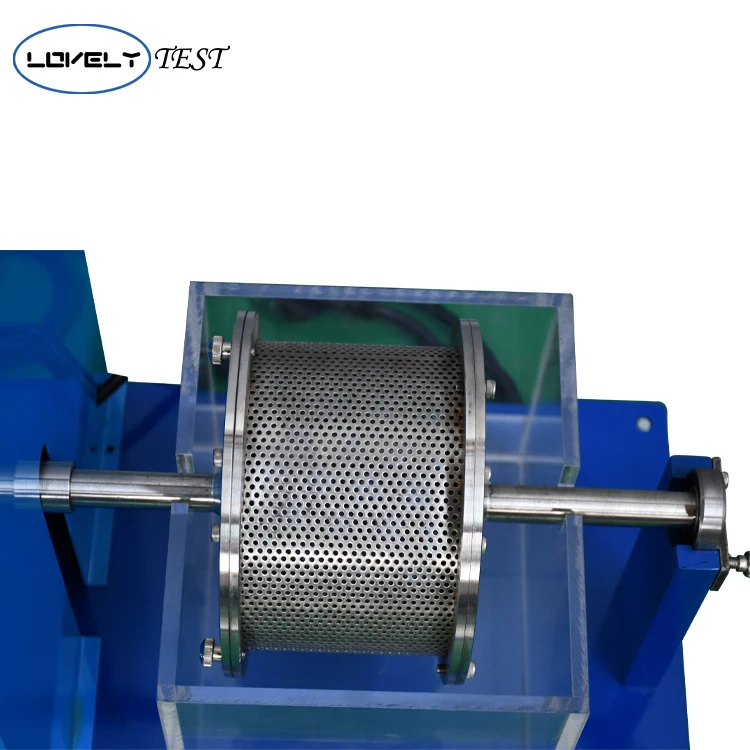

3. What is the standard sieve aperture size of the apparatus?

The Slake Durability Apparatus is equipped with a standard sieve aperture of 2mm for accurate material separation during testing.

4. What is the recommended specimen size for testing?

The specimen size specifications range from 40g to 60g, allowing flexibility for different types of material testing.

5. What are the dimensions of the water tank used in the apparatus?

The water tank has a volume of 200mm x 170mm x 120mm, providing ample space for the testing process.

6. What are the dimensions of the sieve tube?

The sieve tube has a diameter of 140mm and a length of 100mm, designed to accommodate various test materials.

7. What power supply does the apparatus require?

The Slake Durability Apparatus operates on a 220V 50Hz power supply, but it can be customized to meet specific requirements.

8. How compact is the Slake Durability Apparatus?

The overall dimensions of the apparatus are 1000mm x 400mm x 540mm, making it compact and easy to integrate into testing labs and field setups.

9. What is the power consumption of the apparatus?

The unit consumes 50W of power, making it energy-efficient for continuous operation.

10. What materials can be tested with the Slake Durability Apparatus?

The apparatus is designed to test the durability of rocks, gravel, and slag, particularly clay rocks and weathered rocks.

11. Is the apparatus suitable for both research and quality control?

Yes, the Slake Durability Apparatus is ideal for use in research, quality control, and construction projects.

12. Can the apparatus be used in various environmental conditions?

Yes, it helps assess the stability and performance of materials under different environmental conditions.

13. How many specimens can be tested at one time?

The apparatus can test up to 10 specimens at one time, each weighing between 40g and 60g.

14. What is the construction material of the drum-shaped sample box?

The drum-shaped sample box is made of corrosion-resistant materials, ensuring durability during testing.

15. Where is the Slake Durability Apparatus typically used?

It is widely used in universities, scientific research institutes, and test centers for durability testing of various materials.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading