B21, China Town Mall, Midrand

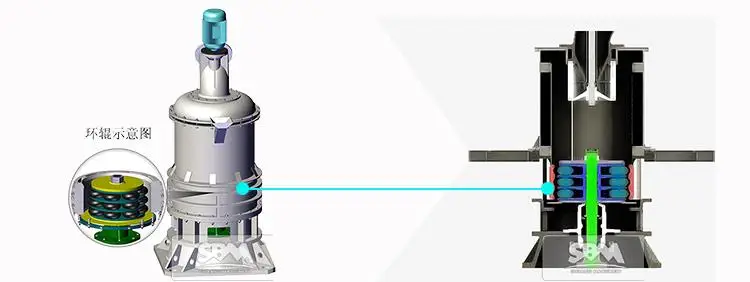

SCM ultrafine mill type 2a grinding mill , dolomite grinding machine , micro ultrafine powder grinding mill

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600063646662

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the SCM Ultrafine Mill Type 2A grind?

The SCM Ultrafine Mill Type 2A is designed to grind non-inflammable, non-explosive, and brittle materials with a Moh's hardness of under six, such as dolomite, limestone, calcite, talc, barite, and kaolin.

2. What is the maximum output capacity of the SCM Ultrafine Mill?

The output capacity ranges from 400 kg/h to 12,000 kg/h, depending on the model and application.

3. How does the energy consumption of this mill compare to other grinding mills?

The SCM Ultrafine Mill consumes 30% less energy compared to jet mills, mixing grinders, and ball mills for the same final particle size.

4. What is the fineness range that can be achieved with this grinding mill?

The final product fineness can be adjusted between 325 mesh to 2500 mesh, with the capability of reaching D97 ≤ 5μm.

5. How does the SCM Ultrafine Mill reduce dust pollution?

The mill is equipped with a pulse bag filter and muffler, which significantly reduces dust pollution and noise, ensuring a cleaner working environment.

6. What industries can benefit from using the SCM Ultrafine Mill?

Industries such as paint, coatings, plastics, rubber, chemicals, and pharmaceuticals can benefit from the fine powders produced by this mill.

7. What is the working principle of this grinding mill?

The working principle involves feeding crushed raw material into the mill, where it is ground by the roller and ring, separated by air, and collected while larger particles are returned for further grinding.

8. What kind of maintenance is required for the SCM Ultrafine Mill?

The mill is designed with no rolling bearings or screws in the grinding cavity to minimize wear issues, but regular inspection and cleaning of the dust collection system are recommended.

9. What are the technical specifications of the different models?

The models vary in max feed size, final size, output, main motor power, grinding path number, and revolving speed. For example, the SCM8021 has a max feed size of ≤10 mm and outputs 400-4500 kg/h.

10. Is the SCM Ultrafine Mill suitable for grinding large quantities of material?

Yes, the mill is capable of handling large quantities of material efficiently, with output capacities ranging from 400 kg/h to 12,000 kg/h.

11. Can the grinding fineness be adjusted during operation?

Yes, the fineness of the final product can be adjusted based on the specific requirements of the application.

12. What safety features are included in the SCM Ultrafine Mill?

The mill is designed to minimize hazards associated with dust explosion risks, as it operates under controlled pressure conditions and includes a dust collection system.

13. What are the key advantages of using the SCM Ultrafine Mill over traditional grinding methods?

Key advantages include higher grinding efficiency, lower energy consumption, adjustable fineness, and reduced dust pollution.

14. Is installation of the SCM Ultrafine Mill complicated?

Installation is straightforward, but it is recommended to follow the manufacturer's guidelines and seek professional assistance for optimal setup.

15. What is the expected lifecycle of the mill's parts?

The ring and roller are forged from special materials, offering a lifecycle that is 2-3 times longer compared to impact mills or turbo mills.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading