B21, China Town Mall, Midrand

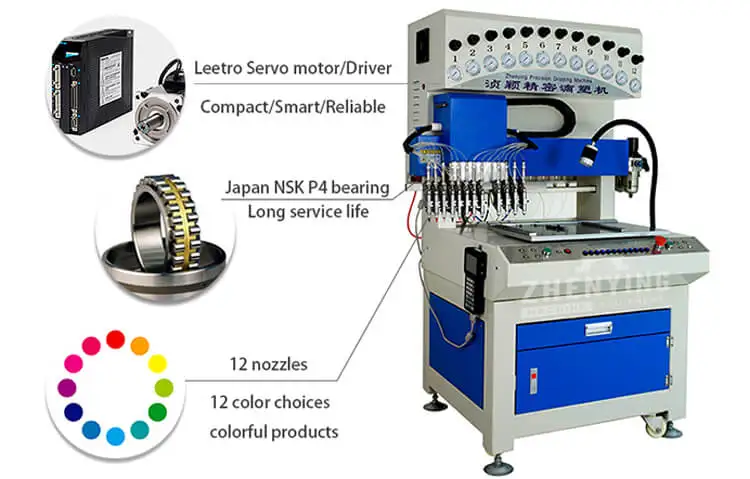

Rubber Slipper Strap Injection Moulding Machine For Pvc Slipper Strap

- Section : Machinery

- Category : Apparel Machinery

- SKU : 60831224475

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Rubber Slipper Strap Injection Moulding Machine used for?

It is an automatic injection moulding system designed to produce PVC/soft-PVC products including slipper straps and uppers, PVC labels, luggage tags, shoe soles, coaster/cup mats, fridge magnets, keychains, zipper heads, USB covers, car mats and small soft-PVC gifts/ornaments.

2. What are the machine's main specifications?

Model: ZY-P08D. Power: 8 kW. Working area: 550 × 350 mm. Air pressure: 0–6 kg/cm2. Weight: approx. 280 kg. Machine size: 950 × 900 × 1460 mm. Voltage options should be confirmed with the supplier for your region.

3. What is the production capacity / throughput?

Typical output is up to 20,000 pieces per 8-hour shift under optimal conditions. The system is capable of continuous 24-hour operation when properly maintained.

4. How much energy does the machine consume?

Total installed power is 8 kW. The double-deck shaping oven and energy-saving design reduce overall electricity consumption; actual energy use depends on production schedule and settings.

5. How many operators are needed and what training is required?

The system is labour-efficient and typically requires two operators for full processing. Operation is straightforward and operators can become competent after short-term training provided by the supplier or factory trainers.

6. How large a factory area is required?

The machine has a small footprint and the whole production line requires about 12.5 m2 of floor space. Individual machine dimensions are 950 × 900 × 1460 mm.

7. Which materials can be processed?

Primarily PVC and soft PVC formulations used for slipper straps and similar small products. The machine can handle a range of PVC compounds and related materials—confirm compatibility with your specific compound before production.

8. What mould/tooling considerations should I know?

Mould size must fit within the working area (550 × 350 mm). The machine supports customized moulds; CNC engraving is recommended for high-precision mould manufacturing. The control system allows per-unit adjustments to match different product molds.

9. What auxiliary equipment is recommended or included?

Main machine components: automatic dripping machine, double-deck shaping oven, cooling table, base material dripping machine. Support equipment commonly used: CNC engraving machine, mixing machine, vacuum machine, and sandblast machine.

10. Does the machine have automatic controls and error protection?

Yes. It features a precise control system for automated production which reduces human error and improves pass rate. Each production unit can be independently controlled (contingency production system) to accommodate different products.

11. What maintenance is required?

Regular maintenance includes cleaning molds and nozzles, checking heaters and electrical connections, ensuring pneumatic lines are leak-free, lubricating moving parts as specified, and replacing worn consumables. Follow the supplier's maintenance schedule for best performance.

12. Are spare parts and after-sales service available?

Most suppliers provide spare parts and after-sales support including installation, commissioning and operator training. Confirm spare-parts availability, lead times and warranty terms with the seller prior to purchase.

13. Is the machine safe to operate and what safety features are included?

The machine reduces manual handling through automation, lowering human-error risks. Standard safety features typically include emergency stop, safety guards around hot/cold zones and required electrical grounding. Confirm exact safety features with the supplier and ensure operator PPE and workplace safety protocols are followed.

14. Can the machine run continuously (24/7) and what about reliability?

Yes — the machine is designed for continuous operation and the listing states it can run 24 hours smoothly. Continuous reliability depends on correct installation, proper ventilation/cooling, scheduled maintenance and using recommended consumables.

15. How do I order, customize or get lead time information?

To order or customize, provide product drawings, desired cycle/time/production rate and any electrical/voltage requirements. The supplier will confirm mould specs, auxiliary equipment needed, price and lead time. Lead time varies by order size, mould production and shipping—confirm with the manufacturer before placing an order.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading