B21, China Town Mall, Midrand

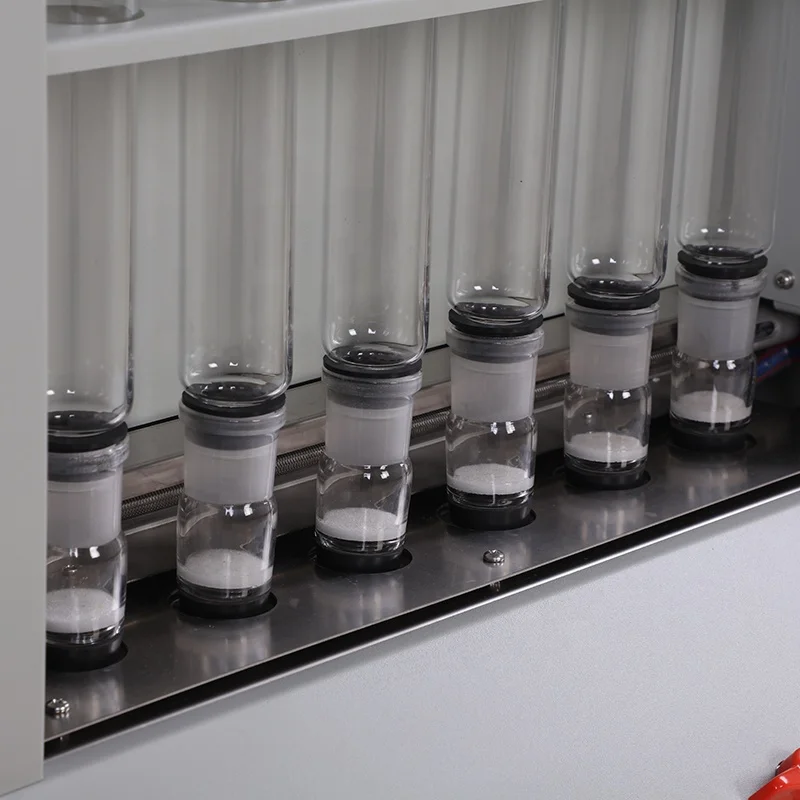

Raw Fiber Analyzer Using acid-base digestion method For grains food feed

- Section : Consumer Electronics

- Category : Test Instruments

- SKU : 1600458846658

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What does the QT Raw Fiber Analyzer measure?

It measures raw and coarse fiber content in grains, food, feed and other agricultural products using an acid-base digestion method.

2. Which analytical method does this analyzer use?

It uses the acid-base digestion method, a widely accepted procedure for determining crude/raw fiber content.

3. How many samples can be processed at once?

The model CXC-06 processes up to 6 samples per test/run.

4. How long does a complete analysis take?

About 100 minutes per run, including approximately 40 minutes acid digestion, 40 minutes alkali digestion, and 20 minutes for filtration and washing.

5. What is the reproducibility and accuracy of results?

Typical reproducibility is well within acceptable lab limits. Specifically, for raw fiber levels < 10% the absolute error is ≤ 0.4%; for levels > 10% the absolute error is ≤ 4%.

6. What types of samples are suitable?

Suitable for cereal grains (wheat, corn, barley), processed food, animal feed ingredients and other agricultural or sideline products where raw/coarse fiber content is required.

7. What sample preparation is required?

Provide representative, homogenized samples according to your lab SOP or relevant standard methods (e.g., dry and grind to a consistent particle size). Follow the chosen method's sample weight and preparation instructions.

8. What reagents and consumables are needed?

Standard acids and bases used for acid-base digestion (typically reagents like sulfuric acid and sodium hydroxide), filter media, wash solvents and appropriate waste containers. Consumables are generally not supplied with the instrument.

9. What are the water supply requirements?

Water pressure greater than 1.5 MPa and water temperature below 20°C are required for operation.

10. What are the power, size and weight specifications?

Power: AC 220V / 50Hz, 2800W. Size: 670 × 450 × 670 mm. Weight: approximately 30 kg.

11. What safety precautions should be followed?

Use appropriate PPE (gloves, goggles, lab coat), operate in a well-ventilated area or fume hood when handling strong acids/bases, follow chemical handling and waste disposal regulations, and ensure staff are trained on emergency procedures.

12. How should the analyzer be maintained and cleaned?

Rinse and clean digestion vessels and filtration components after each run, check seals and valves regularly, replace filter media and worn parts as needed, and follow the manufacturer's maintenance schedule for periodic inspections and servicing.

13. Can this analyzer be used to run official standard methods (e.g., AOAC/ISO)?

Yes — it implements the acid-base digestion approach used in many official methods. To ensure compliance, follow the specific AOAC/ISO method protocols (reagent concentrations, sample sizes, timing) used in your lab.

14. How should I validate and calibrate the instrument?

Perform initial qualification tests, run blanks and certified reference materials, check reproducibility with replicate samples, and schedule routine performance checks. Follow your lab QA/QC procedures to document accuracy and precision.

15. Where can I get spare parts or technical support?

Contact the manufacturer or authorized distributor for spare parts (heaters, valves, filters, electrical components) and technical service. Keep the model number (CXC-06) and product details available when requesting support.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading