B21, China Town Mall, Midrand

Professional H-class cyclone industrial concrete cement dust extractor

- Section : Machinery

- Category : Other Cleaning Equipment

- SKU : 62498184514

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Professional H-class cyclone industrial concrete cement dust extractor?

A heavy-duty industrial dust extractor designed for concrete and cement work. It uses a patented cyclone and Auto Pulsing self-cleaning system, twin Ametek motors, and an OSHA-compliant 2-stage filtration system (primary cylindrical filters + 2 x H13 HEPA) to capture hazardous concrete dust during grinding and floor preparation.

2. What does H-class mean for this dust extractor?

H-class indicates the unit is built for hazardous dusts (such as silica from concrete). It uses high-efficiency HEPA filtration (2 x H13 HEPA filters) and a sealed multi-stage system to minimize operator and site exposure to fine respirable dust.

3. What are the key features of the extractor?

Two Ametek motors for strong suction, patented Bersi Auto Pulsing automatic self-cleaning (no air compressor or manual cleaning), OSHA-compliant 2-stage filtration with three rotating cylindrical primary filters and 2 x H13 HEPA filters (99.99% @ 0.3 µm), and continuous operation capability for floor grinding applications.

4. Which models and voltage options are available?

Two models are referenced: AC22 (240 V, 50/60 Hz) and AC21 (120 V, 50/60 Hz). Both models are rated at 2.4 kW power.

5. What are the electrical and performance specifications?

Power: 2.4 kW (both models). Current draw: approximately 9.6 A for the 240 V model and ~18 A for the 120 V model. Maximum vacuum: 240 mBar. Maximum airflow: 400 m3/h.

6. What are the unit's physical dimensions and weight?

Dimensions: 570 x 710 x 1300 mm. Weight: 53 kg.

7. Is this extractor suitable for use with concrete grinders?

Yes. It is specifically designed for concrete floor grinding and is ideal for grinder working widths below 600 mm.

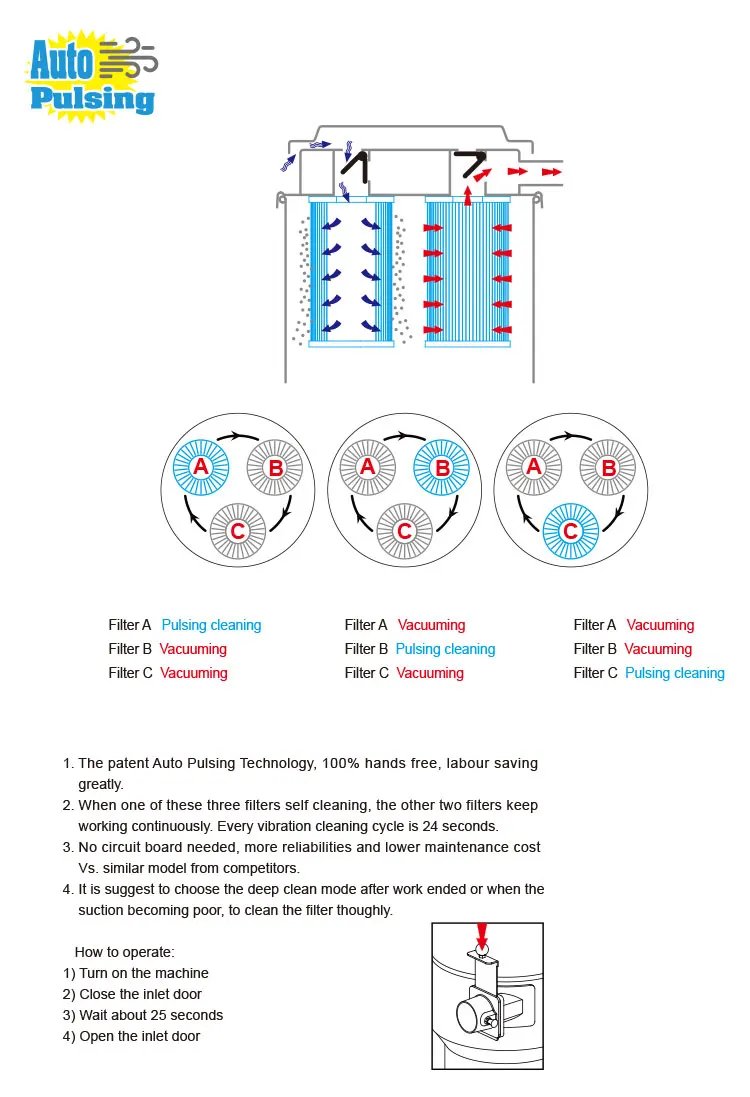

8. How does the patented Auto Pulsing technology work?

The Bersi patent Auto Pulsing system cycles the primary cylindrical filters through timed pulsing cleaning so each filter is cleaned in sequence. This removes the need for manual cleaning or an external air compressor and helps maintain constant suction for uninterrupted operation.

9. What filtration standards and certifications does it meet?

The unit uses 2 x H13 HEPA filters with 99.99% efficiency at 0.3 µm and the HEPA filters are tested/certified to EN1822-1 and IEST RP CC001.6. The system is described as OSHA-compliant for industrial dust control.

10. How often do filters need to be inspected or replaced?

Inspection frequency depends on usage and dust load. The Auto Pulsing reduces manual cleaning and extends filter life, but you should inspect filters regularly for damage or excessive pressure drop and replace the H13 HEPA filters per the manufacturer's guidelines or whenever performance degrades.

11. How should collected concrete/cement dust be emptied and disposed of?

Treat collected material as potentially hazardous (H-class). Follow local and national regulations for hazardous dust disposal. Use appropriate PPE (respirator, gloves), avoid creating dust when emptying, and place waste in sealed containers or bags for disposal according to site procedures.

12. Can this extractor operate continuously during long grinding jobs?

Yes. The Auto Pulsing automatic cleaning strategy is designed to maintain filtration performance and suction without interrupting operation, enabling continuous work on extended jobs.

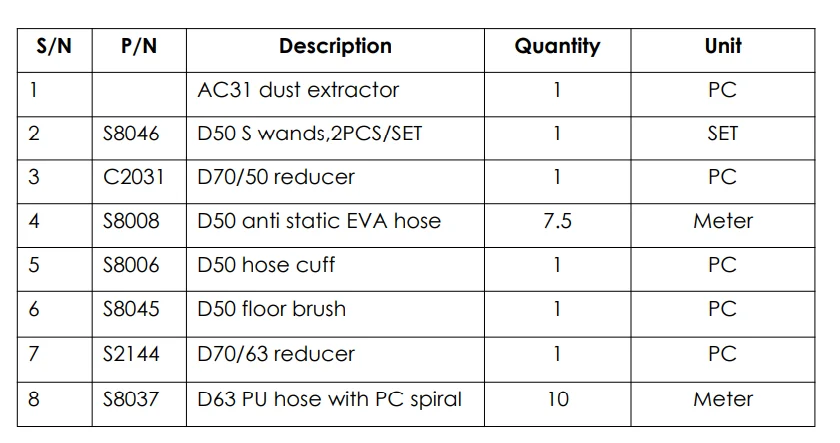

13. Which accessories or hoses are required for connection to grinders?

The extractor works with standard industrial hoses and adaptors compatible with your grinder's dust port. Use the correct diameter and recommended fittings for optimal suction. Consult the supplier for specific hose adaptors and accessory kits for your grinder model.

14. What safety precautions should operators follow?

Wear appropriate PPE (respirator certified for silica/concrete dust, eye protection, gloves). Ensure electrical connections meet local codes and the correct voltage model is used. Follow filter change, emptying, and cleaning procedures to avoid exposure. Adhere to OSHA/local regulations for respirable crystalline silica and hazardous dust handling.

15. Where can I get more technical details or noise/emissions data?

For detailed technical sheets (including noise levels, exact filter surface area, spare parts, and maintenance schedules), contact the manufacturer or your supplier. They can provide full specifications, certification documents, and recommended service intervals.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading