B21, China Town Mall, Midrand

Professional Concrete Core Drill Machine

- Section : Machinery

- Category : Drilling Rigs

- SKU : 1600642923412

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Professional Concrete Core Drill Machine used for?

It is a high-performance core drilling rig designed for frequent drilling in concrete and reinforced concrete for tasks such as creating holes for plumbing, electrical conduits, anchor bolts and sampling.

2. What are the speed settings and the maximum core diameters for each speed?

The product listing specifies three speeds with corresponding maximum core diameters: 1400 r/min — up to 400 mm; 2800 r/min — up to 200 mm; and 3120 r/min — up to 100 mm. (The original spec included "31200 r/min", which appears to be a typo; confirm exact rpm with the manufacturer or product manual.)

3. Can the machine drill at an angle?

Yes. It has a quick-release bracket that allows angular drilling from 0 to 90 degrees for angled core holes.

4. Is the machine portable for on-site use?

Yes. The rig includes castors for faster movement on site and can be fitted with an optional vacuum suction cup base to mount without a permanent fixing bracket, making setup quicker and more flexible.

5. What materials can this drill handle?

It is designed for drilling through concrete and reinforced concrete. For other materials (masonry, stone, asphalt, etc.) check compatibility of the core bit and drilling method first.

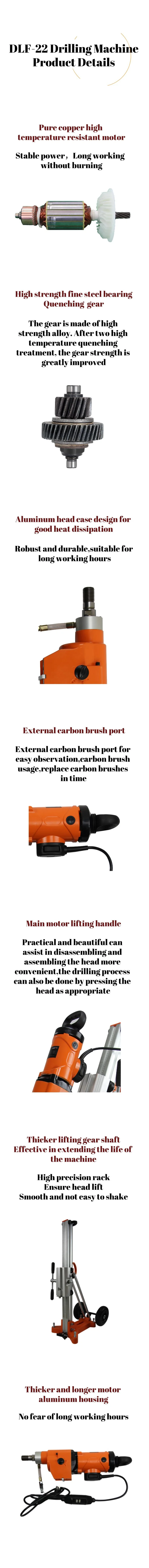

6. What is the benefit of the column being die-cast magnesium alloy aluminum?

The full magnesium alloy die-cast aluminum column gives high precision, reduced weight, high strength, and improved resistance to oxidation and corrosion compared with plain aluminum or steel columns.

7. How does the gearbox protect the motor and improve performance?

The drill uses three speed-regulating gears to extend the drilling range and match torque to core diameter. Gears are precision-made and heat-treated for hardness and wear resistance, and they run in a liquid gear oil bath to ensure adequate lubrication and cooling, which protects the motor and improves efficiency.

8. Can the drill be used without a fixing bracket?

Yes—if equipped with the optional vacuum suction cup base you can operate without a fixing bracket. For the safest operation, ensure the vacuum base is rated for the load and surface, or use the fixing bracket or other secure anchoring when required.

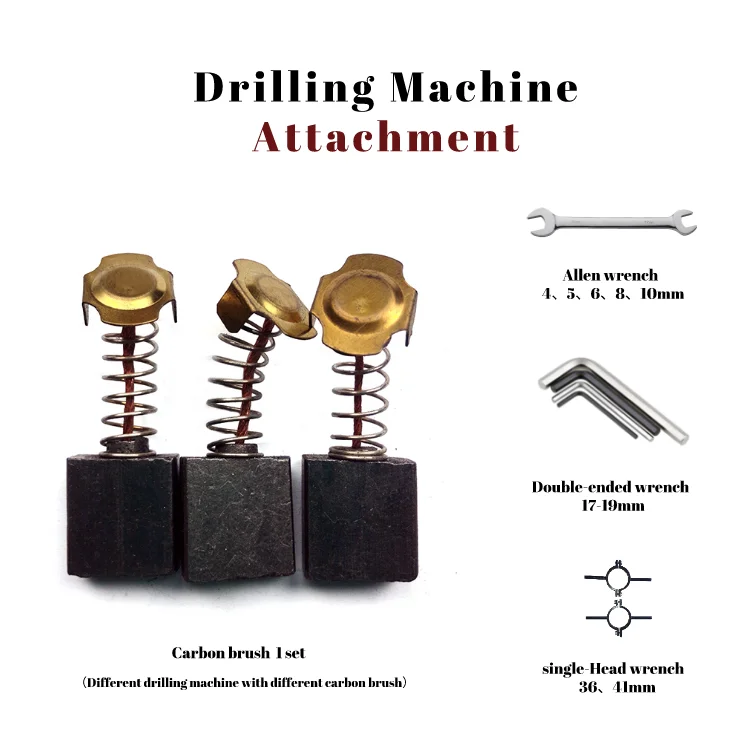

9. What attachments and accessories come with the machine?

The description lists "PRODUCT ATTACHMENT" but does not specify details. Common attachments for core drilling rigs include core bits of various sizes, water feed for wet drilling, feed handles, a vacuum base (optional), and mounting brackets. Confirm the exact included items with the seller or product sheet.

10. Is wet or dry drilling recommended?

The product description does not explicitly state, but core drilling in concrete is commonly done wet to reduce dust, cool the bit and increase bit life. Always follow the core bit manufacturer's guidance and local regulations for dust control when considering dry drilling.

11. What maintenance is required to keep the machine working well?

Regularly check and maintain gearbox oil level (liquid gear oil bath), inspect gears and seals, keep the column and feed mechanism clean and lubricated, check mounting hardware and vacuum base integrity, and service/replace motor brushes or bearings per the manual. Follow the manufacturer's maintenance schedule.

12. What safety precautions should I follow when using this drill?

Use appropriate PPE (eye protection, hearing protection, gloves, dust control), secure or use the vacuum base properly, ensure stable mounting before drilling, use water suppression for wet drilling where appropriate, avoid loose clothing, and follow lockout procedures for maintenance. Also follow local site safety rules and the machine manual.

13. How do I choose the correct core bit size and speed?

Match the core diameter to the machine's speed/torque capability: larger diameters require lower speeds and higher torque (use the lowest gear for the largest cores). Choose the bit type for concrete/reinforced concrete and follow the bit manufacturer's recommended rpm range. If in doubt, consult the product manual or supplier.

14. Does the machine come with a warranty or after-sales support?

Warranty and after-sales support are not specified in the description. Check the seller's or manufacturer's warranty policy and available service centers before purchase.

15. Who should I contact if I need spare parts or technical support?

Contact the manufacturer or the authorized dealer who sold the machine for spare parts, consumables (core bits, seals), and technical support. Keep your model number (DLF-44) and purchase information handy when requesting service.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading