B21, China Town Mall, Midrand

Pre vacuum veterinary sterilization equipment

- Section : Medical Supplies

- Category : Veterinary Instrument

- SKU : 1600614168787

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the chamber volume range for the Pre-Vacuum Veterinary Sterilization Equipment?

The chamber volume ranges from 150 liters to 800 liters.

2. What materials are used for the door panel of the sterilization equipment?

The door panel is made of 316L (304) stainless steel, with precision polishing treatment on the inner surface.

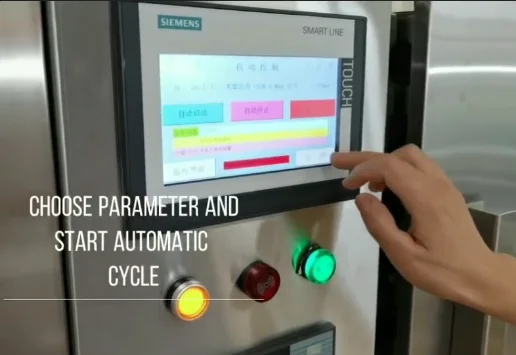

3. How does the control system of the equipment work?

The equipment features a PLC (Programmable Logic Controller) with a touch screen interface for intuitive operation and precise control.

4. What are the safety features included in this sterilization equipment?

The equipment includes a safety interlock that prevents the door from opening when there is pressure in the chamber, ensuring compliance with pressure vessel safety standards.

5. Can the sterilization cycles be customized?

Yes, the equipment has 5 programmable cycle programs and 2 test programs that users can set according to their needs.

6. Is there a built-in documentation feature?

Yes, the equipment is equipped with a recorder and printer for comprehensive documentation of sterilization cycles.

7. What is the maximum temperature the chamber can withstand?

The chamber is designed to withstand temperatures up to 139℃.

8. What language options are available for the interface and documentation?

The interface and documentation are available in multiple languages, including English and Russian.

9. What type of door configurations does the equipment offer?

The equipment offers a double door configuration for enhanced sterilization efficiency and safety.

10. How does the pre-vacuum cycle work?

The pre-vacuum cycle uses a vacuum pump to remove chamber air more than 99% before sterilization, improving steam penetration and temperature uniformity.

11. What accessories are included with the sterilization equipment?

The equipment includes high-quality components from brands such as Mitsubishi/Siemens, Airtac, Pall, and Gemu for optimal performance.

12. How can I download cycle data from the equipment?

The equipment features a USB port that allows users to download cycle data to memory devices.

13. What type of validation documents are provided with the equipment?

The equipment includes IQ (Installation Qualification), OQ (Operational Qualification), PQ (Performance Qualification), DQ (Design Qualification), SAT (Site Acceptance Testing), and FAT (Factory Acceptance Testing) for validation and compliance.

14. What is the structure design of the sterilization chamber?

The chamber is designed in a horizontal rectangular shape to optimize space and efficiency.

15. What features enhance the reliability of the pipeline system?

The pipeline system features stainless steel pipes without dead angles for complete drainage, high-quality pneumatic valves, and an antibacterial air filter to prevent secondary pollution.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading