B21, China Town Mall, Midrand

Portable Plate Compactor Machine Plate Road Pavement

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 1600275619898

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 22 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

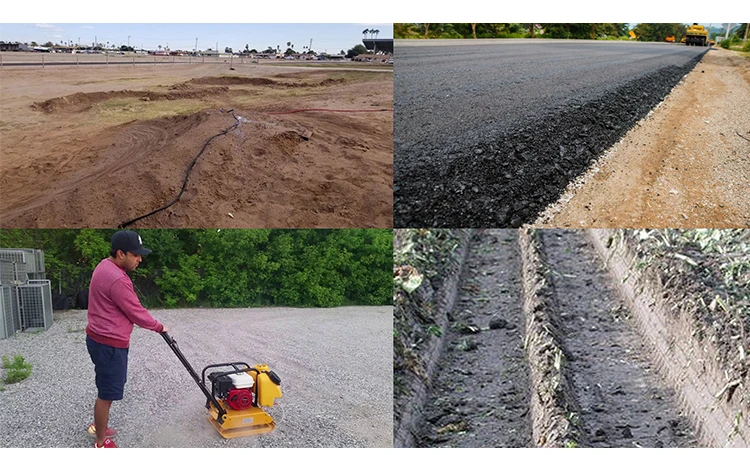

1. What is the Portable Plate Compactor Machine used for?

This plate compactor is used for compacting soil, sand, gravel and asphalt in road pavement, sidewalks, trenches, foundations and landscaping to create a stable, even surface.

2. Which models are available?

Available models are SC-50, SC-60, SC-77, SC-77W, SC-90, SC-100 and SC-140.

3. How do the models differ in plate size and weight?

Plate sizes (L×W mm) by model are: SC-50 535×290, SC-60 570×370, SC-77 570×370, SC-77W 560×475, SC-90 570×450, SC-100 708×450, SC-140 630×500. Net weights (kg) are approximately: SC-50 51, SC-60 69, SC-77 75, SC-77W 80, SC-90 80, SC-100 97, SC-140 110.

4. What is the vibration frequency and why does it matter?

All models deliver about 5,600 vpm (vibrations per minute). Higher vibration frequency improves compaction effectiveness and helps achieve better density in granular and asphalt layers.

5. What is the centrifugal force for each model?

Centrifugal force (kN) by model: SC-50 10 kN, SC-60 10 kN, SC-77 10.5 kN, SC-77W 13.5 kN, SC-90 13 kN, SC-100 20 kN, SC-140 30 kN. Higher force provides deeper and stronger compaction.

6. What travel speeds do the machines reach?

Typical travel speeds are 15–20 m/min for most models. The SC-60 has a higher range of about 20–25 m/min.

7. What is the maximum slope (gradeability) the compactor can handle?

All models have a limited grade ability of approximately 20%.

8. Which engines and fuel types are available?

Engine options include gasoline engines: Lifan 154F (1.4 kW / 3 HP), Honda GX160 (4.1 kW / 5.5 HP), Robin EY20-3C (3.7 kW / 5 HP), Lifan G160F (4.1 kW / 5.5 HP); and a diesel option: Diesel D173F (4.4 kW / 6.0 HP). Fuel type depends on the selected engine (gasoline or diesel).

9. How do I choose the right model for my job?

Select based on plate size (coverage per pass), centrifugal force (compaction depth and intensity), weight and portability, and engine power. For larger areas and deeper compaction choose higher-force/heavier models (SC-100, SC-140); for confined spaces and greater portability choose smaller models (SC-50, SC-60).

10. What is the starting system?

All models use a recoil (manual pull) start system.

11. What are the packing dimensions for transport?

Packing sizes (L×W×H mm) by model are: SC-50 740×360×550, SC-60 890×430×660, SC-77 850×530×670, SC-77W 880×530×670, SC-90 580×470×650, SC-100 700×480×580, SC-140 670×500×800.

12. What basic maintenance is required?

Regular checks include engine oil level and changes, air filter cleaning/replacement, fuel system inspection, tightening bolts, cleaning the plate and vibration housing, and checking for loose or worn parts. Follow the engine and machine manual for specific intervals.

13. What safety precautions should operators take?

Wear hearing and eye protection, safety boots and gloves. Do not operate on slopes steeper than the 20% gradeability, avoid loose clothing near moving parts, keep bystanders away, and ensure stable footing when operating or transporting the machine.

14. Can this compactor be used on asphalt and new pavements?

Yes — plate compactors like these are suitable for compacting asphalt and repairing pavements when using the correct model and technique for the material and layer thickness.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading