B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

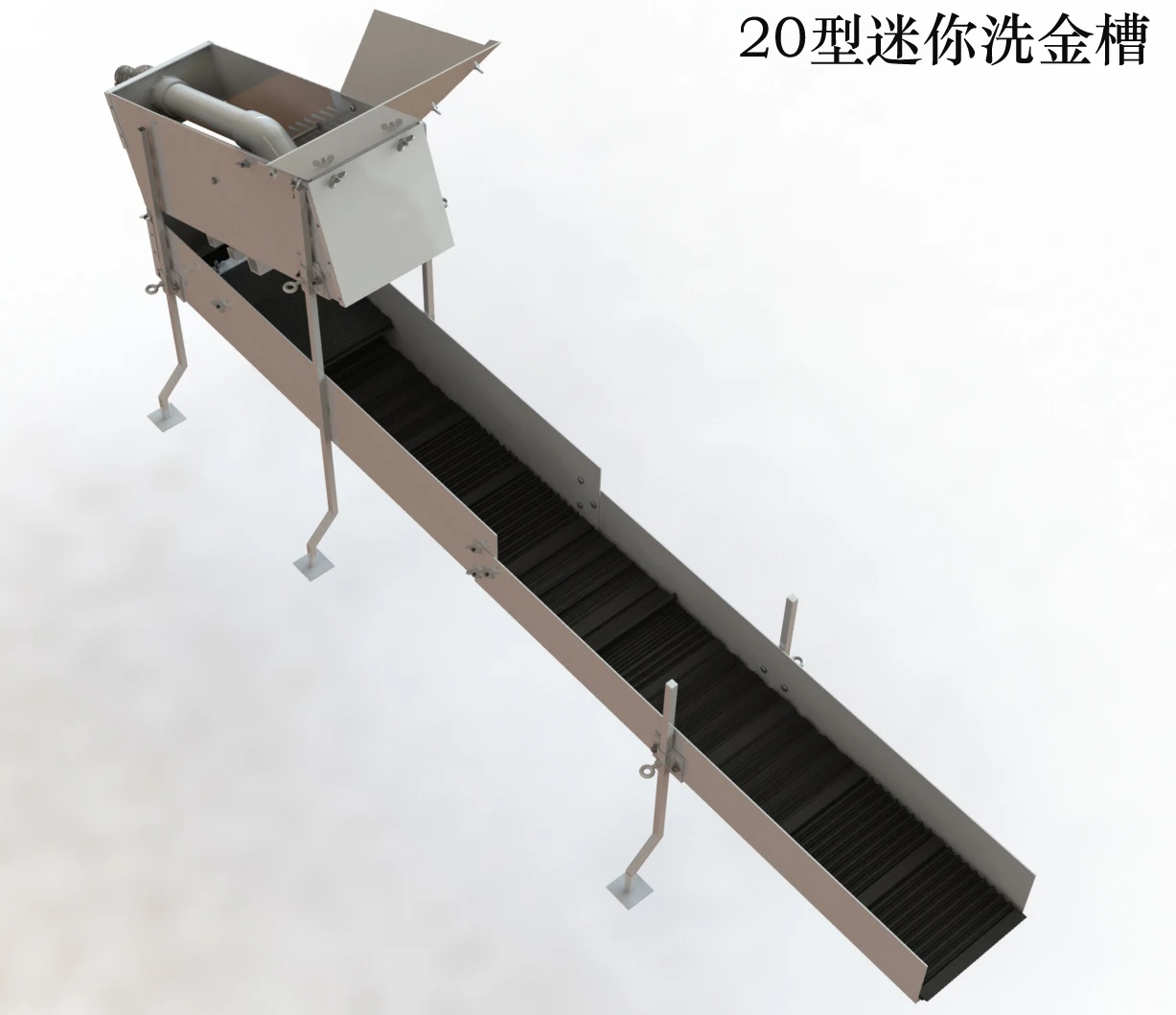

1. What is the Portable Gold Mining Machine and what is it used for?

The Portable Gold Mining Machine is a lightweight, collapsible sluice-style recovery unit made from aviation aluminum, designed to separate and recover gold from placer materials in small- to mid-scale mining operations and remote locations.

2. What are the key technical specifications of the machine?

According to the product listing: Model 3030; overall dimension reference 240 cm; maximum capacity about 2 ton/hr; net weight approximately 42 kg. For exact dimension breakdowns and model options, please consult the supplier's spec sheet.

3. How much material can it process per hour?

The machine is rated for a maximum capacity of about 2 tons per hour under optimal conditions. Actual throughput depends on feed size, water flow, operator technique and material composition.

4. How portable is the unit and how do I transport it?

The unit is collapsible and lightweight (approx. 42 kg), with adjustable support legs so it can be disassembled and moved by hand or transported on an ATV, small trailer or pickup. Two people can typically carry the main components.

5. What materials is the machine made from and how durable is it?

The frame and body are constructed from aviation-grade aluminum for a high rigidity-to-weight ratio and good corrosion resistance. Wear parts such as rubber mats and sieves are replaceable for extended life in rugged environments.

6. What are the core components (motor, pump, engine) and are they included?

The machine features a reliable motor/pump/engine configuration to ensure steady water flow and material washing. Exact motor/pump specifications and whether they are included can vary by seller—confirm with the supplier when ordering.

7. Does it require special tools or technical skill to install?

Installation is straightforward and the product includes technical guidance for setup. Basic hand tools are usually sufficient. No specialized skills are required, but following the provided instructions ensures optimal performance.

8. What are the power and water requirements to operate the machine?

The machine requires a steady water supply (it features a head box with a quick-connect water system) and a compatible power source for the pump/motor. Exact power ratings depend on the motor/pump option—check the product documentation or ask the supplier for the specific power requirements.

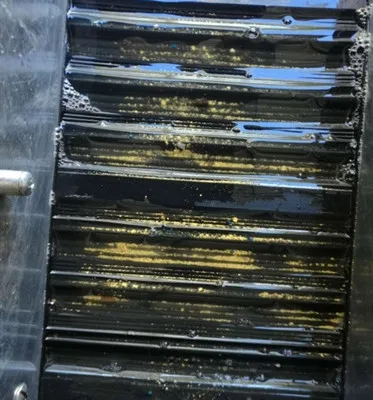

9. How high is the gold recovery rate and what affects it?

The unit is engineered for a high recovery rate, but actual recovery depends on factors including feed particle size, classifier/screening efficiency, water flow, sluice angle, mat condition and operator technique. Proper setup and regular maintenance maximize recovery.

10. How do I clean and maintain the machine?

Regular maintenance includes: rinsing and removing trapped material from rubber mats and sieves after each run, inspecting and tightening supports and fasteners, checking hoses and quick-connects for leaks, and servicing the pump/motor per the manufacturer's recommendations. Keep the unit dry during long-term storage to prevent corrosion of non-aluminum parts.

11. Are replacement parts and accessories available?

Common consumables and wear parts such as full-set rubber mats, sieves, hoses and head-box components are typically available. Ask the supplier for spare parts lists and availability when purchasing to ensure you can keep the unit operational in the field.

12. Can I customize the appearance of the machine?

Yes. The product is offered with customizable color options based on customer requests so you can match personal preferences or branding. Confirm color lead times and any minimum order requirements with the seller.

13. Is the unit suitable for remote or harsh environments?

Yes. The aviation aluminum construction, collapsible design and strong support legs with adjustable working angle make it well-suited for remote locations. However, environmental conditions, abrasive material and prolonged wet storage can affect component life—regular inspection is recommended.

14. Are there legal or environmental considerations I should be aware of?

Yes. Gold recovery and mining activities are regulated in many jurisdictions. Always obtain necessary permits, comply with local mining and water-use regulations, and follow environmental best practices (proper tailings disposal, minimizing water pollution and land disturbance). The supplier cannot provide legal permits—check local authorities.

15. What warranty and after-sales support are provided?

Warranty terms and after-sales support can vary by manufacturer or distributor. The product listing mentions technical guidance for installation; for warranty length, parts coverage and service procedures, confirm details with your supplier before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading