B21, China Town Mall, Midrand

ORTUR laser router OLM-3LE engraving machine portable mini engraver laser metal machine 10w For home

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 11000006972821

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 22 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the ORTUR laser router OLM-3LE engrave and cut?

The ORTUR laser router OLM-3LE can engrave and cut materials such as wood, leather, acrylic, fabric, and bamboo. The LU2-10A model can also handle anodized aluminum and stainless steel.

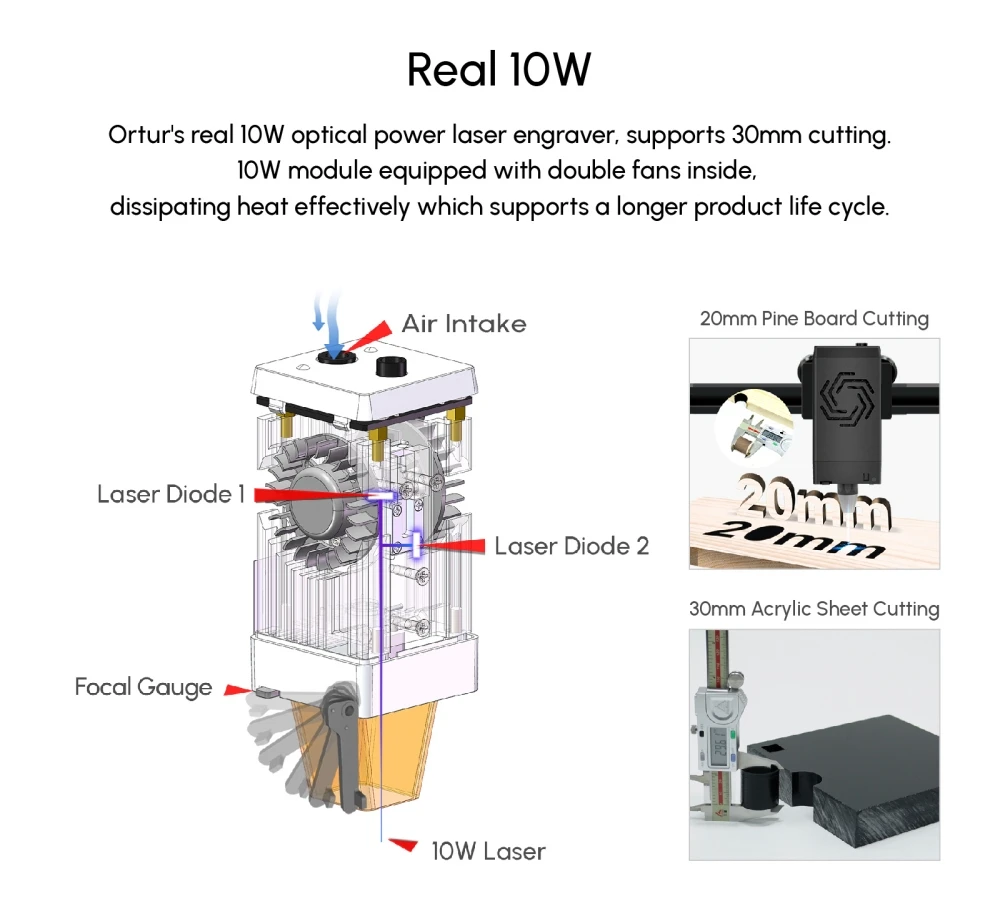

2. What is the output power of the ORTUR laser router OLM-3LE?

The ORTUR laser router OLM-3LE offers different models with output power ranging from 4.5-5.5W for LU2-4 models to 9.5-10.5W for the LU2-10A model.

3. How long is the service life of the ORTUR laser router OLM-3LE?

The service life of the ORTUR laser router OLM-3LE is over 10,000 hours, ensuring long-lasting performance.

4. Can the ORTUR laser router OLM-3LE engrave stainless steel?

Yes, the LU2-10A model of the ORTUR laser router OLM-3LE can engrave stainless steel, while other models may not support this material.

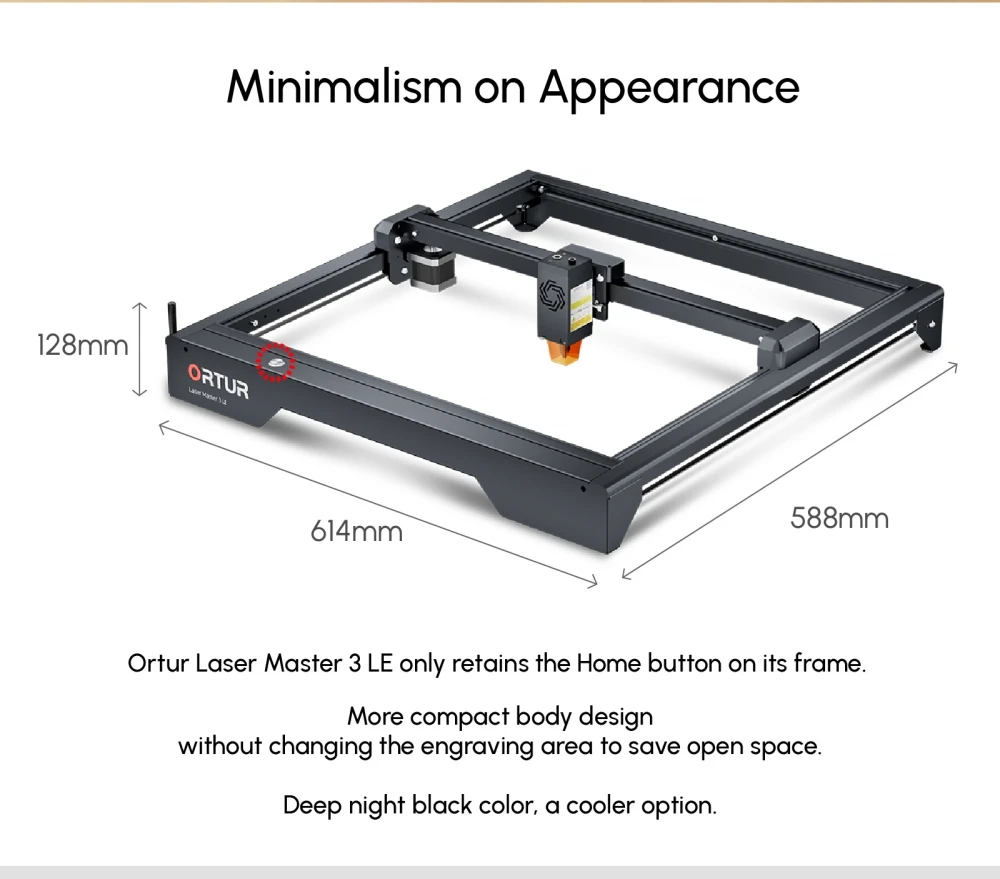

5. Is the ORTUR laser router OLM-3LE portable?

Yes, the ORTUR laser router OLM-3LE is designed to be compact and lightweight, making it portable and easy to integrate into various systems.

6. What is the focal distance of the different models?

The LU2-4L model has a focal distance of 50mm, the LU2-4S model has a focal distance of 30mm, and the LU2-10A model has a focal distance of 50mm.

7. What types of engraving and cutting tasks is the ORTUR laser router OLM-3LE suitable for?

The ORTUR laser router OLM-3LE is suitable for precise cutting and engraving applications across various materials, making it ideal for both industrial and creative tasks.

8. What is the laser wavelength of the ORTUR laser router OLM-3LE?

The laser wavelength for all models of the ORTUR laser router OLM-3LE is 445+5nm.

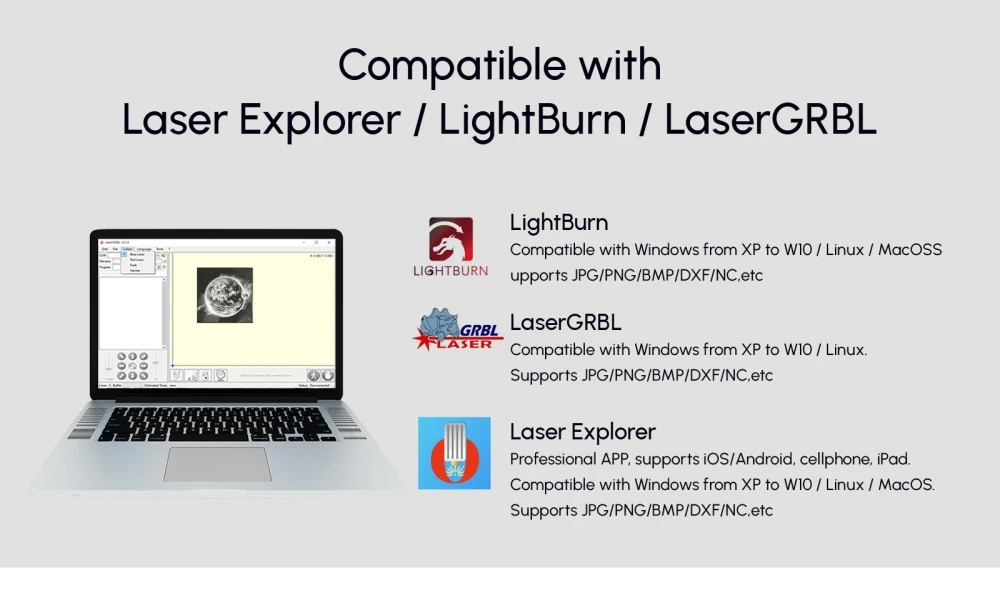

9. How do I set up the ORTUR laser router OLM-3LE?

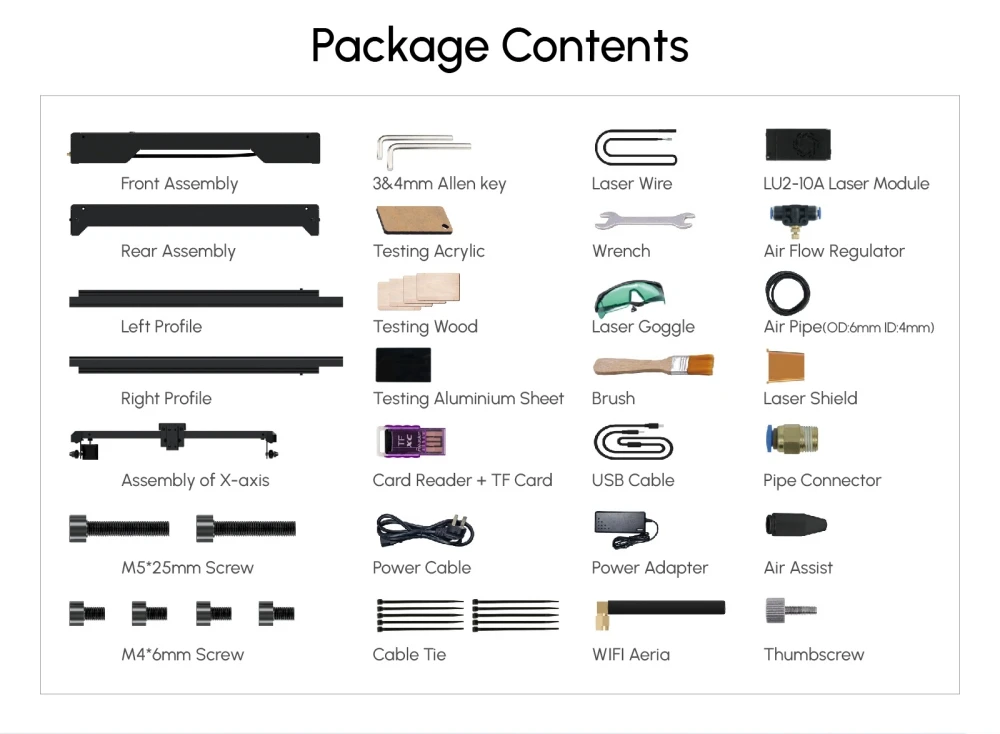

Setting up the ORTUR laser router OLM-3LE involves assembling the components, connecting it to a power source, and configuring it with compatible software. Detailed instructions are provided in the user manual.

10. What is the spot size of the different models?

The spot size for the LU2-4L model is 0.17x0.25mm, for the LU2-4S model it is 0.12x0.15mm, and for the LU2-10A model it is 0.05x0.1mm.

11. Can I use the ORTUR laser router OLM-3LE for commercial purposes?

Yes, the ORTUR laser router OLM-3LE is suitable for both personal and commercial use, providing high precision for various engraving and cutting tasks.

12. Is there a warranty for the ORTUR laser router OLM-3LE?

Warranty details may vary by retailer, but typically the manufacturer provides a limited warranty covering defects in materials and workmanship. Please consult the retailer for specific terms.

13. What safety precautions should I take while using the ORTUR laser router OLM-3LE?

When using the ORTUR laser router OLM-3LE, always wear eye protection, ensure proper ventilation, and avoid direct contact with the laser beam. Follow all safety guidelines provided in the user manual.

14. What power supply does the ORTUR laser router OLM-3LE require?

The power requirements vary by model, with the LU2-4 models requiring 20W and the LU2-10A model requiring 40W. Ensure you use a compatible power supply.

15. What is the difference between the LU2-4 and LU2-10A models?

The main difference is the output power: LU2-4 models have 4.5-5.5W, suitable for lighter engraving tasks, while the LU2-10A has 9.5-10.5W, making it ideal for cutting through thicker materials.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading