B21, China Town Mall, Midrand

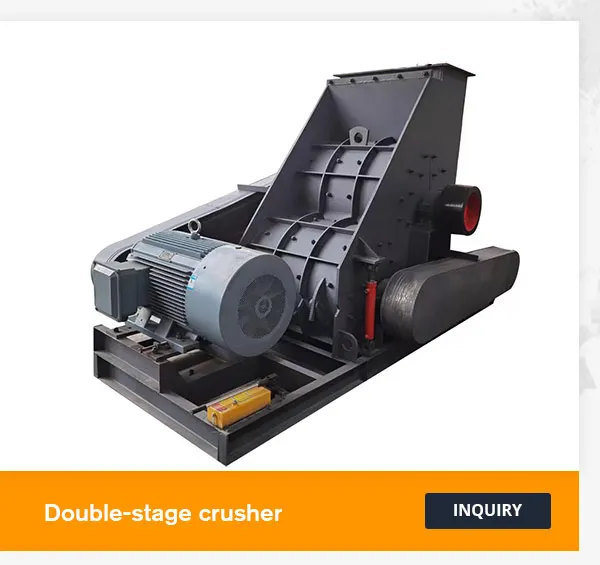

Mini Sand Press achine Iron Coal Stone Rubble Granit Hammer

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600625708328

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 25 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Mini Sand Press Machine / Two-stage Crusher?

It's a compact two-stage hammer crusher designed to crush materials such as coal gangue, carbon mud, coal slime, iron ore, stone, rubble and granite into sand-like product without using a screen.

2. What materials can this machine process?

It can process coal, clean coal, coal gangue, coal slime, carbon mud, iron ore, rubble, stone and granite. The machine accepts a wide variety of brittle to medium-hard materials.

3. Does the machine require a screen or sieve?

No. The Two-stage Crusher is designed without a screen, which eliminates screen clogging and residual residue and enables 100% yield for the feed material.

4. What is the maximum feed size and moisture content allowed?

There is no strict limit on feed particle size or moisture content—slimy, wet or sticky material can be fed directly. Very large lumps should be pre-broken to practical sizes for uniform feed.

5. What is the typical finished product size?

Finished particle size depends on rotor speed, hammer type and operational settings. The machine produces sand-like material; final gradation can be optimized by adjusting these parameters.

6. What is the machine's throughput or capacity?

Capacity varies with material type, feed size, moisture and operational settings. For an accurate capacity estimate, provide material properties and desired output to the supplier for sizing.

7. How is wear handled and what spare parts are common?

Wear parts include hammers, liners, and bearings. These are replaceable. Regular inspections of hammers and liner plates and timely replacement will maintain performance.

8. What maintenance is required and how often?

Routine maintenance includes checking/torquing bolts, inspecting and replacing worn hammers and liners, lubricating bearings, and clearing feed/ discharge points. Frequency depends on operating hours and material abrasiveness.

9. What power and installation requirements are needed?

Power requirements depend on motor size selected for the model. The machine should be mounted on a solid foundation or skid and connected to an appropriate electrical supply with proper grounding and protection.

10. How much dust and noise does the machine generate, and how can they be controlled?

As with most crushers, there is dust and noise during operation. Mitigation measures include installing a dust-collection system, enclosing the unit, using silencers, and providing personal protective equipment for operators.

11. Is the machine portable or fixed?

Mini models can be configured for semi-portable installation on a skid; typical installations are fixed on a foundation. Mobility options depend on the selected configuration and mounting.

12. Can product gradation be customized?

Yes. Final particle size and gradation can be influenced by hammer design/material, rotor speed and feed management. Work with the supplier to specify desired output characteristics.

13. What safety features or precautions are recommended?

Recommended precautions include lockout/tagout during maintenance, guarding of rotating parts, emergency stop buttons, regular inspection of fasteners and wear items, and PPE for operators.

14. Is there warranty and after-sales support?

Warranty and after-sales support vary by manufacturer. Typical offerings include a limited parts warranty and availability of spare parts and technical assistance; confirm terms with your supplier.

15. How do I select the right model for my application?

Provide the supplier with feed material type, maximum feed size, moisture content, desired throughput and product specification. They will recommend a model and configuration (motor size, hammer type, mounting) to meet your needs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading