B21, China Town Mall, Midrand

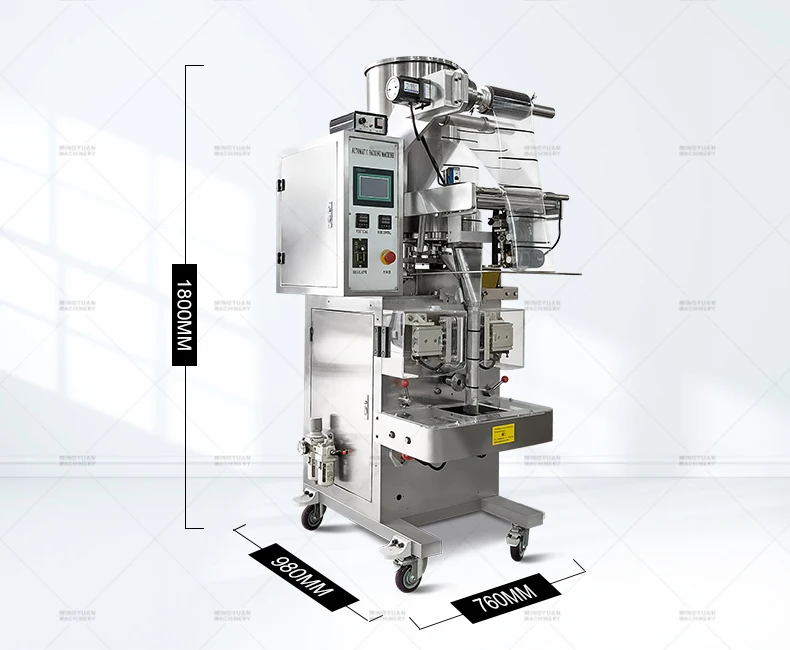

Mingyuan MY-K100 Automatic Packing Machine

- Section : Machinery

- Category : Packaging Machines

- SKU : 1600685545815

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 27 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the packing speed of the Mingyuan MY-K100?

The MY-K100 runs typically at 30–60 bags per minute; it is commonly configured to operate around 50 bags/min depending on product, bag size and film type.

2. What bag sizes and film widths does the MY-K100 support?

Bag length: 50–150 mm; bag width: 25–120 mm; film width: 50–260 mm. These ranges make it suitable for a wide variety of small-format packages.

3. What packing volume (product fill) can this machine handle?

The MY-K100 handles product fills from about 5 ml up to 100 ml, suitable for small granular, particulate or measured solid products.

4. Which products is the MY-K100 suitable for?

Typical applications include granulated sugar, popcorn, salt, beans, spices and seeds. For liquids or very wet products, please consult the manufacturer about available filling attachments or modifications.

5. What sealing types and bag shapes can it produce?

The machine supports three-side seal, four-side seal and back-seal styles and can form common pillow, stick and sachet shapes shown in the sample display.

6. What are the machine dimensions and weight?

Machine dimensions are 760 mm × 980 mm × 1800 mm and the unit weight is approximately 300 kg.

7. What are the electrical and air requirements?

Electrical: 220 V AC, 50 Hz, 1.6 kW. Compressed air: nominally 0.65–0.8 MPa with approximately 100 L/min consumption.

8. What packaging films are compatible with the MY-K100?

The MY-K100 is designed to work with common flexible packaging films within the specified film width range. For optimal results, use films suitable for heat sealing (single- or multi-layer laminated films) and confirm compatibility with your film supplier.

9. How easy is it to operate and change formats?

The machine is user-friendly with intuitive controls and mechanical adjustments for bag size and sealing. Format changeovers are designed to be straightforward; exact changeover time depends on operator experience and the extent of mechanical adjustments required.

10. What routine maintenance is required?

Routine maintenance includes daily cleaning of product contact areas, periodic lubrication of moving parts, inspection of sealing jaws and film feed components, and timely replacement of wear parts. Follow the manufacturer's maintenance schedule for best results.

11. Are spare parts and technical support available?

Yes — spare parts and technical support are available from the manufacturer or authorized dealers. Contact your supplier for lead times, recommended spare parts kits and service options.

12. What safety and regulatory considerations should I know?

Operate the machine with all guards in place and train personnel on safe operation. Use appropriate hygiene and safety procedures for food packaging. Verify any regional regulatory or certification requirements with the supplier prior to purchase.

13. How can I evaluate the MY-K100 for my product before buying?

Request a sample test or demonstration from the manufacturer or distributor using your product and packaging film. Provide product characteristics (particle size, flowability, fill volume) and desired bag dimensions to get an accurate evaluation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals