B21, China Town Mall, Midrand

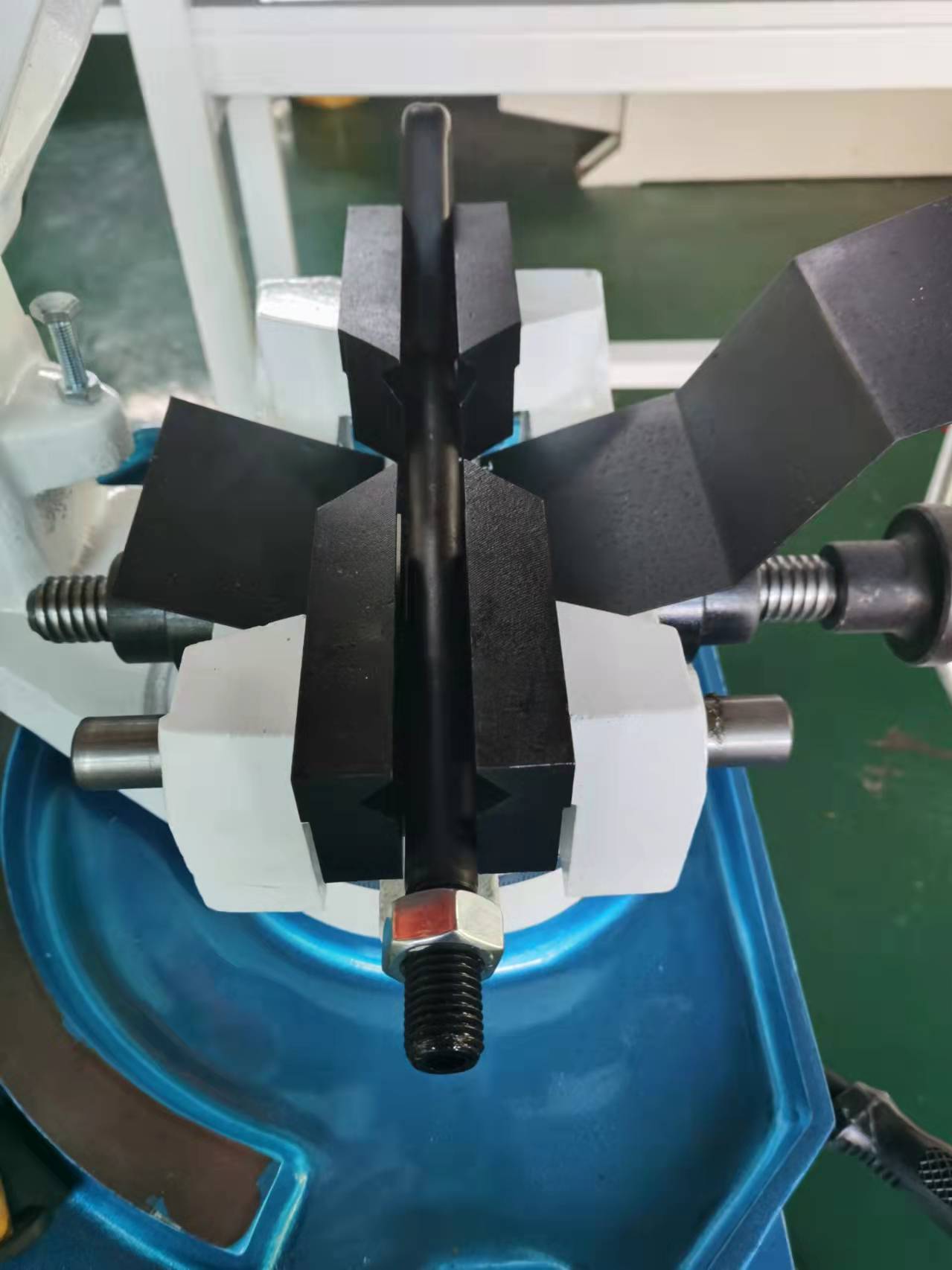

MC315A CNC Pipe Cutting Machine with Cutting Blocks and Automatic Gas Cutting Capability

- Section : Machinery

- Category : CNC industrial Machinery

- SKU : 1600591726764

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 22 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the MC315A CNC Pipe Cutting Machine?

The MC315A is a pipe cutting machine featuring CNC control, cutting blocks and automatic gas cutting capability, designed for industrial metal cutting applications.

2. Which materials can the machine cut?

It can process a wide range of materials including stainless steel, carbon steel, aluminium / aluminium alloys, brass/copper, iron and some plastics (verify plastic type with the supplier).

3. What is the maximum cutting thickness?

Maximum cutting thickness listed is 38 mm.

4. What blade sizes are available?

Blade/cutter sizes available for this model are 200 mm, 300 mm and 315 mm.

5. Does the machine support automatic gas cutting and what gas is used?

Yes — the MC315A has automatic gas cutting capability. Automatic gas cutting typically uses oxy-fuel (oxygen plus a fuel gas such as acetylene or propane). Confirm the recommended gas type and fittings with the supplier for your specific configuration.

6. Is the machine fully automatic or manual?

The product name indicates CNC and automatic gas cutting capability; the specification also lists 'Automation: Manual'. This usually means CNC controls the cutting path while some operations (loading, clamping or certain adjustments) may be manual. Please confirm the exact automation level and workflow with the supplier before purchase.

7. What are the electrical requirements and rated power?

Voltage is listed as 220 V and the rated power is 2.4 (units not explicitly stated—commonly kW). Verify electrical specifications with the supplier for your country and site.

8. What are the machine weight and dimensions?

Weight is listed as 200 kg. Length, width and height dimensions were not specified in the provided data—contact the supplier for exact footprint and shipping dimensions.

9. What warranty and core-component coverage come with the machine?

Core components (bearing, gearbox, motor, gear, reducer, cutter head) have a 1-year warranty. Overall warranty is listed as 12 months. Check warranty terms and what is covered/excluded with the seller.

10. Is after-sales support provided?

Yes. The listing indicates video technical support is available, and a video outgoing-inspection and machinery test report are provided prior to shipment.

11. Are cutting blocks and other accessories included?

The product name specifies cutting blocks. Standard blade sizes are listed (200/300/315 mm). For a complete list of included accessories and optional extras (fixtures, cutting heads, gas hoses, clamps), confirm with the supplier.

12. Which industries and applications is the machine suitable for?

Typical applications include building material shops, machinery repair shops, manufacturing plants, food & beverage and restaurant equipment fabrication, retail metalwork, construction, energy & mining and other industrial metal cutting tasks.

13. Is the machine portable and how is it installed?

The machine is described as portable and efficient; however at ~200 kg it will likely require handling equipment (forklift or pallet jack) for movement and professional installation/leveling on site. Confirm installation requirements with the supplier.

14. How is maintenance and spare part availability?

Core components are standard industrial parts (bearings, gearbox, motor, gears, reducer, cutter head). Regular maintenance (cleaning, lubrication, blade checks) is recommended. Ask the supplier about spare-part kits, lead times and local support options.

15. Where is the machine manufactured, and how do I order or get lead-time information?

Place of origin is Jiangsu, China. Showroom is listed as none. Lead times, shipping options and ordering terms are not included in the spec—contact the seller or manufacturer directly for pricing, minimum order quantity, lead time and shipping details.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading