B21, China Town Mall, Midrand

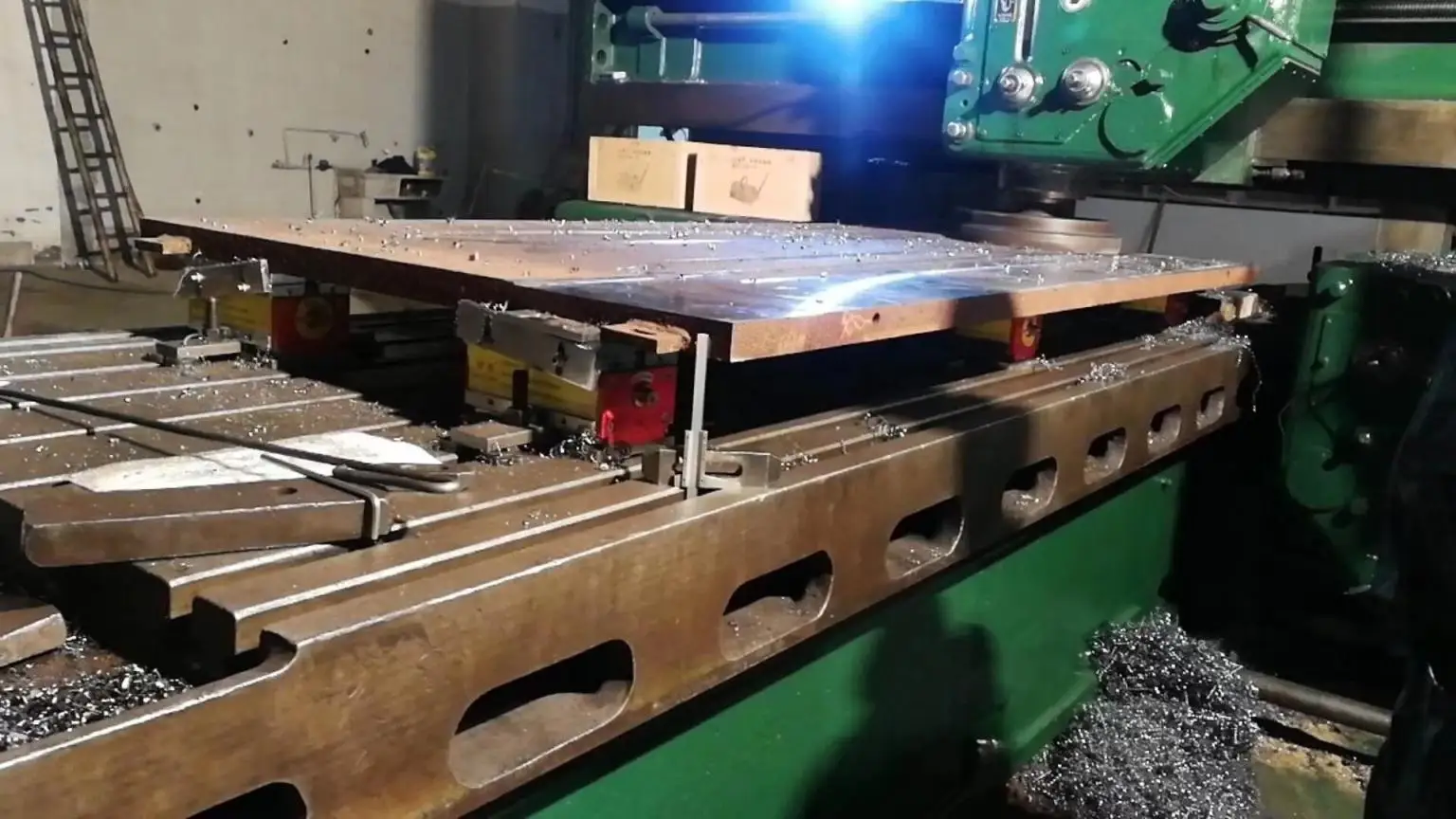

LXT series permanent magnetic chuck workbench magnet table LXT-75

- Section : Electrical & Tools

- Category : Machining

- SKU : 62351025627

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the LXT-75 permanent magnetic chuck workbench magnet table?

The LXT-75 is a model in the LXT series of permanent magnetic chuck tables designed for precision tooling and machining. It uses high-performance NdFeB magnets and a durable steel body to hold ferromagnetic workpieces securely during machining, inspection, and layout operations.

2. What are the specifications (dimensions, weight and holding force) of the LXT-75?

LXT-75 dimensions: 175 × 72 × 76 mm. Net weight: 8.5 kg. Rated holding force (suction): 750 kg.

3. What materials are used in the LXT series chucks?

The chucks are built from durable steel housings combined with high-grade NdFeB (neodymium iron boron) permanent magnets for strong, long-lasting magnetic performance.

4. How does the independent chuck design benefit my work?

The independent chuck design lets you control and position magnetic segments separately for more flexible fixturing, easier alignment of irregular or smaller parts, and finer adjustments for precision operations.

5. Is the LXT-75 customizable?

Yes. The LXT series supports OEM and ODM customization, including size, color, and configuration adjustments to meet specific industrial or commercial requirements.

6. How do I operate the LXT-75 (power type and switching)?

The LXT-75 is a manually operated permanent magnetic chuck. It uses a mechanical on/off mechanism (lever or equivalent manual actuator depending on configuration) to engage and disengage the magnetic holding force.

7. Which materials can the LXT-75 hold effectively?

The chuck is intended for ferromagnetic materials such as steel and iron. It will not hold non-ferrous materials (aluminum, brass, copper), plastics, or wood unless a ferromagnetic backing or fixture is used.

8. Can I use the LXT-75 for milling, grinding, or drilling?

Yes. The LXT-75 is suitable for many machining processes (milling, drilling, grinding) where stable magnetic fixturing is required. Always follow machining best practices and safety procedures, and ensure the workpiece size and holding force are appropriate for the operation.

9. How should I mount the LXT-75 on my workbench or machine table?

Mounting depends on your setup—common options are placing the chuck on a flat, clean machine table and clamping it in place or bolting it down through fixture holes if your system provides them. Ensure the mounting surface is clean, flat, and rigid to maintain accurate workholding.

10. What maintenance is required for the LXT-75?

Keep the chuck surface and workpieces clean and free of chips, coolant and rust. Periodically inspect for wear or damage. Wipe with a clean, dry cloth after use and apply a light rust inhibitor on uncoated steel surfaces if storing for long periods. Avoid strong impacts and exposure to high temperatures.

11. What safety precautions should I take when using the magnetic chuck?

Keep fingers and tools clear when engaging/disengaging the magnet. Do not use on non-ferromagnetic parts without appropriate fixturing. Avoid exposing NdFeB magnets to high heat or strong mechanical shock. Keep magnets away from pacemakers and sensitive electronic devices.

12. What is the warranty and how is the product packaged for shipping?

The LXT series comes with a 1-year warranty. Products are shipped in sturdy wooden cartons to protect them during transportation.

13. How does the LXT-75 compare to other models in the LXT series (LXT-50, LXT-120, LXT-210)?

Key differences are holding force, size and weight: LXT-50 — 500 kg holding force, 145×72×76 mm, 6.5 kg; LXT-75 — 750 kg holding force, 175×72×76 mm, 8.5 kg; LXT-120 — 1000 kg holding force, 193×108×112 mm, 17.6 kg; LXT-210 — 2000 kg holding force, 229×133×129 mm, 29.4 kg. Choose the model based on required holding capacity and workpiece size.

14. Can I request custom colors or special features for the LXT-75?

Yes. The LXT series supports customization including color and other feature requests via OEM/ODM services. Contact the supplier with your specifications to discuss options and lead times.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading