B21, China Town Mall, Midrand

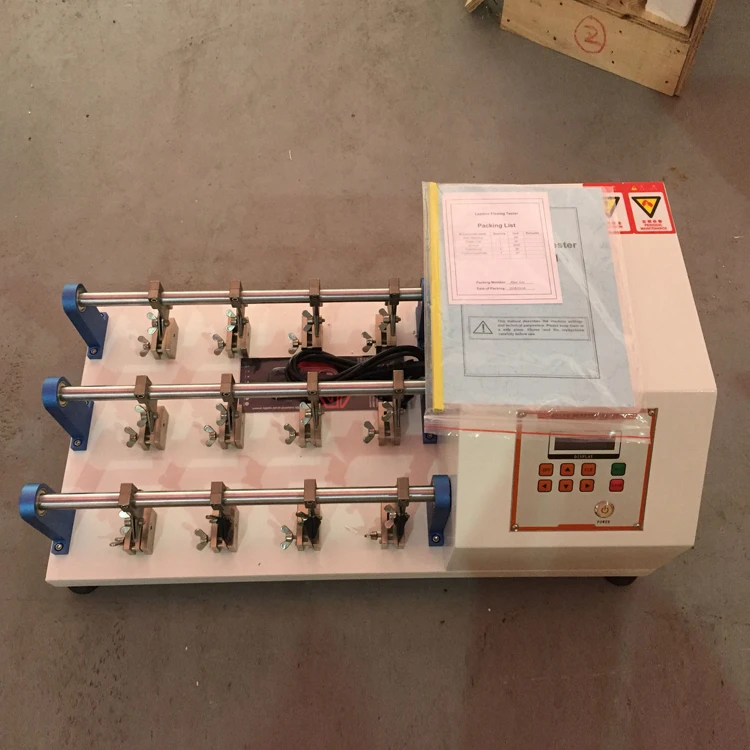

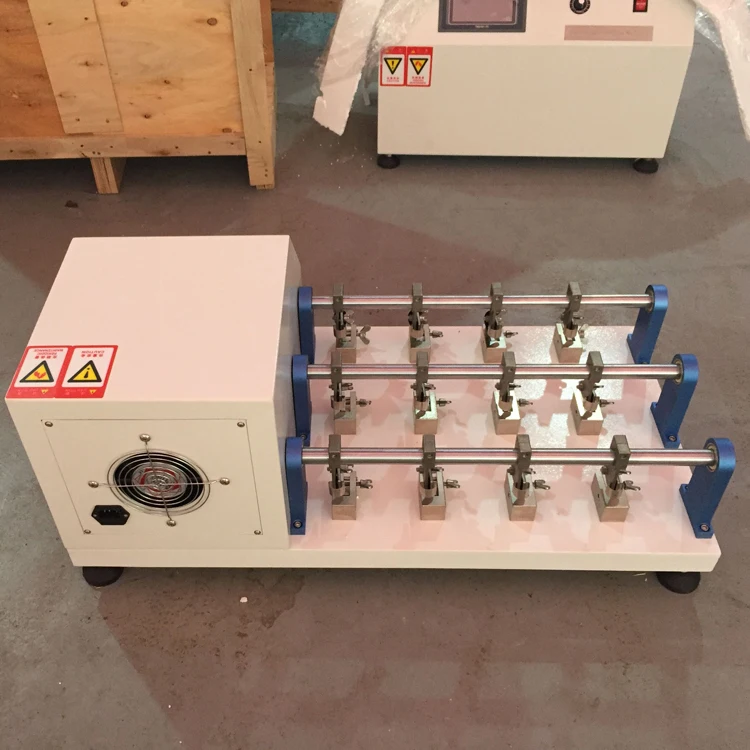

Leather Flex Test Machine, Leather Flexing Tester

- Section : Consumer Electronics

- Category : Testing Equipment

- SKU : 60803827995

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary use of the Leather Flex Test Machine?

The Leather Flex Test Machine is primarily used to test the folding performance and scratch resistance of various leathers and fabrics, making it ideal for industries such as clothing, shoes, and bags.

2. What standards does the Leather Flex Test Machine comply with?

The machine complies with standards BS-3144 and JIB-K6545, ensuring reliable and consistent testing results.

3. What types of materials can be tested with this machine?

The Leather Flex Test Machine can test various types of leather and fabric used in clothing, footwear, luggage, and handbags.

4. How does the testing process work?

The testing process involves nipping the material, twisting, and turning it repeatedly until a specified number of cycles is reached, after which the damage to the tested material is assessed.

5. What is the speed of the Leather Flex Test Machine?

The machine operates at a speed of 100 ± 5 cycles per minute (cpm).

6. What is the specimen size for testing?

The specimen size for testing is 70 mm by 45 mm.

7. What is the bending angle utilized during testing?

The bending angle used during the testing process is 22.5 degrees.

8. What is the weight of the Leather Flex Test Machine?

The machine weighs approximately 60 kg.

9. What are the dimensions of the Leather Flex Test Machine?

The dimensions of the machine are 52 cm in width, 64 cm in depth, and 40 cm in height.

10. What type of power supply is required for the machine?

The Leather Flex Test Machine requires an AC power supply of 220V and 50Hz.

11. Who can benefit from using the Leather Flex Test Machine?

This machine is beneficial for industries involved in shoe manufacturing, clothing production, luggage and handbag design, as well as research laboratories and commodity inspection departments.

12. Is training required to operate the Leather Flex Test Machine?

While not mandatory, it is recommended to have training or guidance on the correct operation of the machine to ensure accurate testing and safety.

13. Can the machine be used for quality control purposes?

Yes, the Leather Flex Test Machine is ideal for quality control purposes, helping manufacturers ensure that their materials meet industry standards for durability and performance.

14. What kind of maintenance does the Leather Flex Test Machine require?

Regular maintenance includes cleaning, checking for wear and tear, and ensuring that all components are functioning properly to maintain testing accuracy.

15. Where can I purchase the Leather Flex Test Machine?

The Leather Flex Test Machine can be purchased through specialized equipment suppliers or manufacturers that focus on testing machinery for the textile and leather industries.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading