B21, China Town Mall, Midrand

KINGS6000-H Industrial SLA 3D Printer for Model Casting and Digital Plastic 3D Printing

- Section : Consumer Electronics

- Category : 3D Printers

- SKU : 60703267227

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the build size of the KINGS6000-H 3D printer?

The KINGS6000-H has a build size of 600mm x 600mm x 400mm, allowing for large-scale production and intricate model creation.

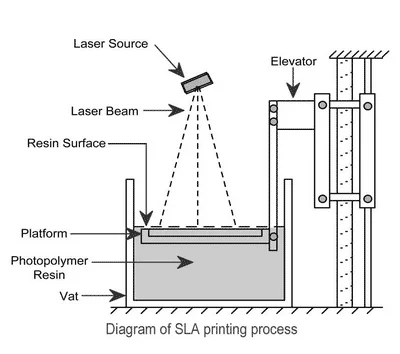

2. What type of technology does the KINGS6000-H use?

The KINGS6000-H uses Stereolithography (SLA) technology which utilizes a laser system to cure photosensitive resin for high precision and detail.

3. What materials can be used with the KINGS6000-H?

The KINGS6000-H is compatible with photosensitive resin, which is essential for achieving fine details and smooth finishes.

4. How does the Intelligent Coating System work?

The Intelligent Position Vacuum Coating system ensures uniform and accurate coating with a layer thickness ranging from 0.05mm to 0.20mm, optimizing the printing process.

5. What is the weight of the KINGS6000-H printer?

The KINGS6000-H weighs approximately 880kg, making it a durable and robust option for industrial use.

6. What are the advantages of using SLA technology over FDM?

SLA can achieve finer print precision (as fine as 0.1mm) and is capable of producing intricate and detailed parts, while FDM typically has a precision of around 0.2mm and may struggle with complex designs.

7. Can the KINGS6000-H operate automatically?

Yes, the KINGS6000-H is fully automatic, reducing the need for manual intervention and enhancing production efficiency.

8. What is the maximum scanning speed of the KINGS6000-H?

The maximum scanning speed of the KINGS6000-H is 10.0m/s, which helps to shorten production cycles.

9. What control software is used with the KINGS6000-H?

The KINGS6000-H uses KING3D Control Software for machine control and can accept STL file formats for 3D design.

10. What is the recommended ambient temperature for operating the KINGS6000-H?

The recommended ambient temperature for operating the KINGS6000-H is between 20-26ºC.

11. How does the Variable Spot Technology enhance print quality?

Variable Spot Technology automatically adjusts the laser power to form spots with different diameters, optimizing printing speed and improving surface finish during the printing process.

12. What kind of laser does the KINGS6000-H utilize?

The KINGS6000-H is equipped with an Nd:YV04 Solid Laser, which provides high precision and enhanced accuracy for complex designs.

13. How does the Germanic Galvanometer Scanner function?

The Germanic Galvanometer Scanner ensures precise laser beam scanning for consistent results throughout the printing process.

14. Is the KINGS6000-H suitable for industrial applications?

Yes, the KINGS6000-H is designed for industrial use, providing long-lasting durability and outstanding performance in demanding environments.

15. What is the printing precision of the KINGS6000-H?

The KINGS6000-H can achieve a printing precision as fine as 0.1mm, making it suitable for complicated and delicate parts.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading