B21, China Town Mall, Midrand

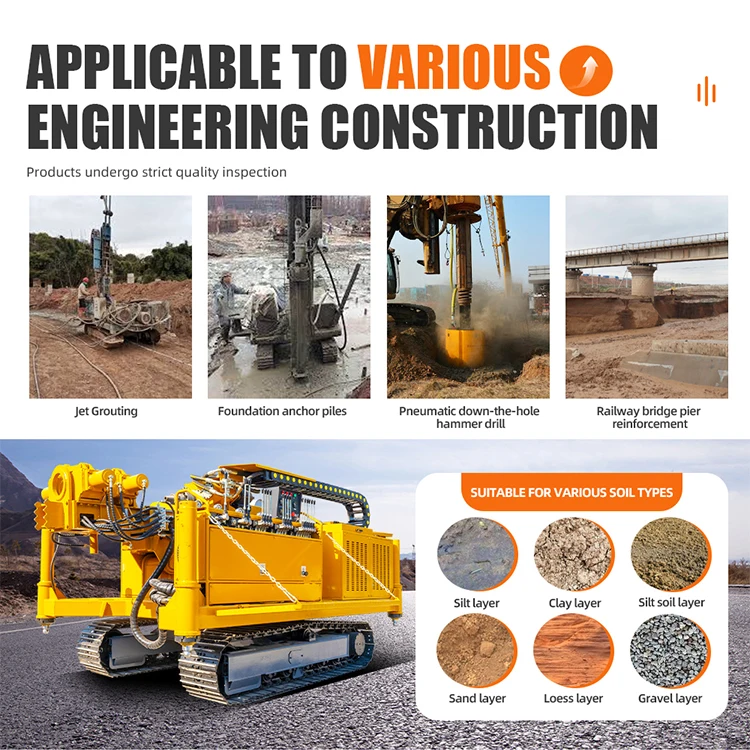

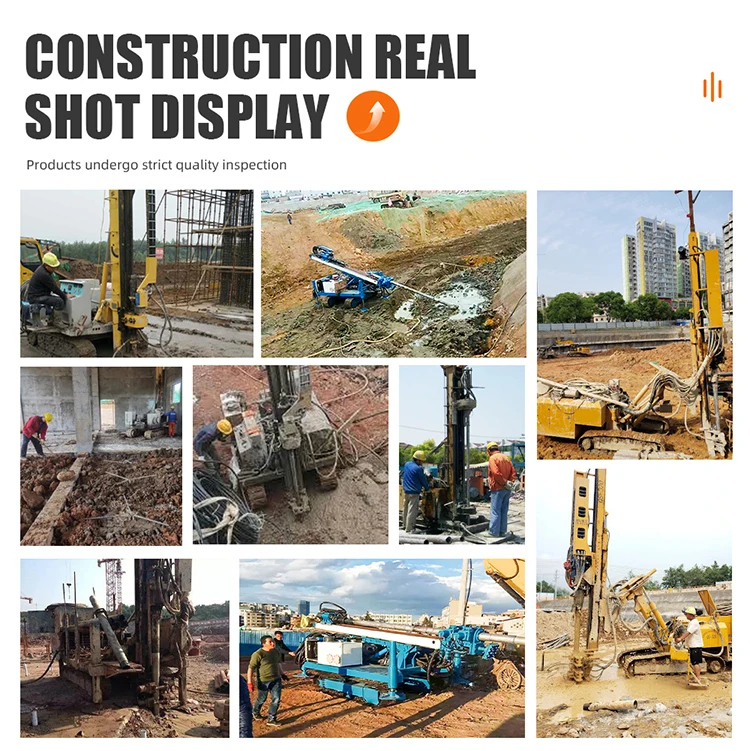

Jet Grouting Equipment anchoring drilling machine for slope-protection project

- Section : Machinery

- Category : Mining Machinery

- SKU : 1601171920256

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary use of the Jet Grouting Equipment anchoring drilling machine?

The primary use of this machine is for the reinforcement of various types of soft foundations, anti-seepage treatment of basements in high-rise buildings, regulation of large rivers and dams, and reinforcement of railway and highway bridge piers.

2. What types of drilling methods can this rig perform?

This drilling rig can perform various methods including ordinary rotary drilling, air down-the-hole hammer drilling, high-pressure jet spraying, self-drilling, and self-blasting.

3. Is the drilling machine suitable for different construction techniques?

Yes, it can be configured for various construction techniques such as fixed spraying, swing spraying, and rotary spraying, as well as single, double, and triple spraying requirements.

4. What are the key features of this jet grouting drilling rig?

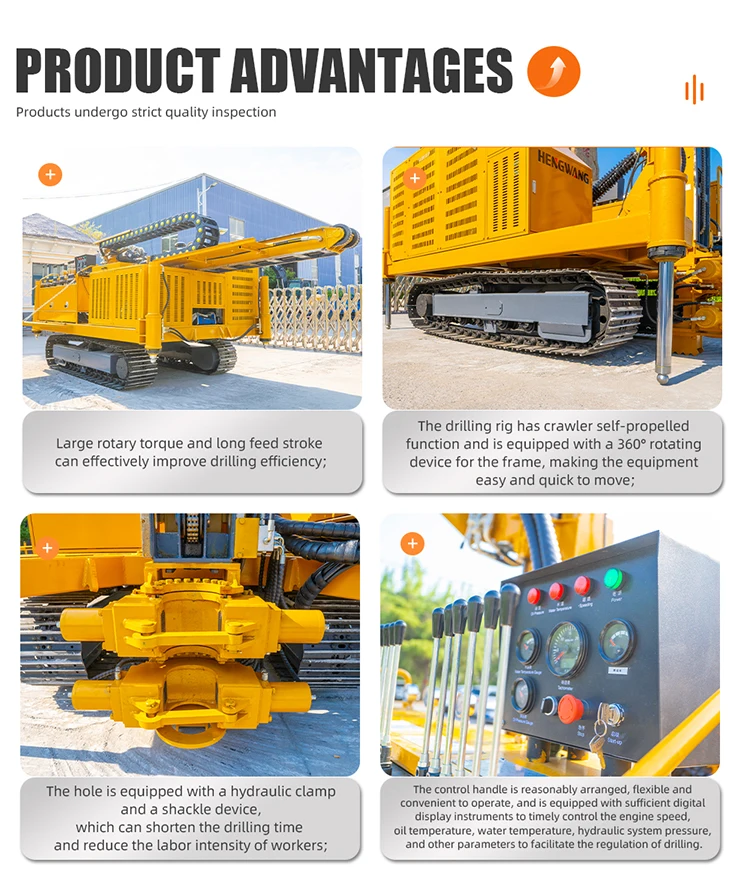

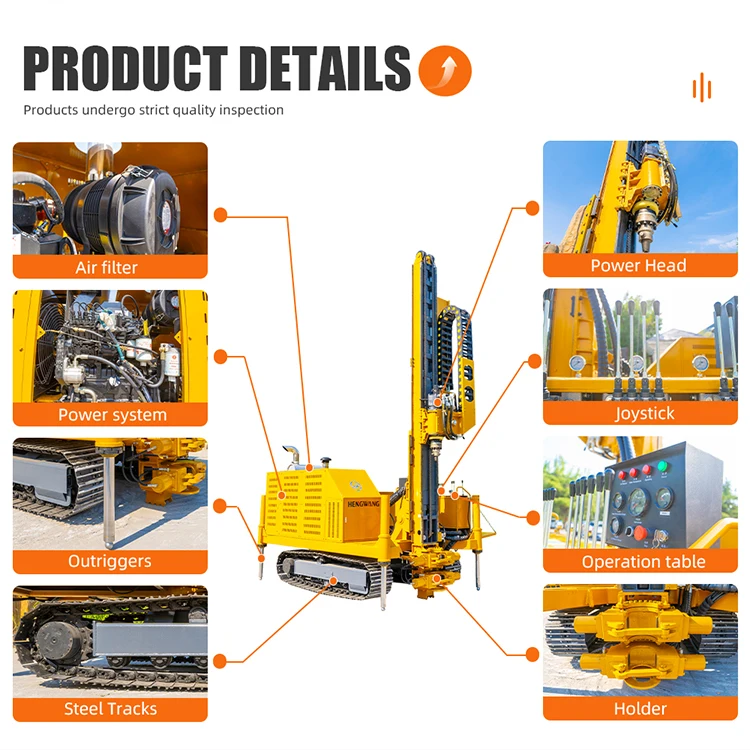

Key features include full hydraulic power head transmission, stepless speed change for high efficiency, a large traction crawler chassis for strong climbing ability, and the capability to drill vertical, horizontal, and oblique holes.

5. Can this machine be used for slope protection projects?

Yes, it is specifically designed for foundation pit and slope anchor support, including anti-floating anchors and jet grouting anchor cables.

6. What is the maximum drilling speed of this rig?

The maximum drilling speed of the rig can reach up to 170 rpm, which significantly enhances work efficiency.

7. What is the benefit of the hydraulic power head transmission?

The hydraulic power head transmission allows for stepless speed changes, which improves drilling efficiency and reduces labor intensity.

8. How does the rig handle different strata?

The rig's design allows it to meet the needs of various strata and different rotary spraying processes by enabling multi-angle construction.

9. How does the rig facilitate equipment shifting?

The rig is equipped with a large traction crawler chassis that provides strong climbing ability and facilitates easy and fast equipment shifting.

10. What is the maximum length of the drill pipe that can be used?

The power head has a long stroke and can be connected to a 3-meter drill pipe, which helps to reduce auxiliary time during operations.

11. What types of projects is this drilling rig suitable for?

It is suitable for various hole-making projects, including foundation reinforcement, slope protection, and anti-seepage treatments.

12. Is the machine easy to operate?

Yes, the combination of hydraulic power and user-friendly controls makes it relatively easy to operate for skilled personnel.

13. Can this rig be used in urban construction environments?

Yes, it is designed for versatility, making it suitable for urban construction projects, including those in tight spaces.

14. What safety features does the rig have?

While specific safety features are not detailed, it is important to follow operational safety guidelines and training to ensure safe use of the drilling rig.

15. How can I maintain the Jet Grouting Equipment?

Regular maintenance should include checking hydraulic systems, ensuring all components are lubricated, and following the manufacturer's guidelines for upkeep.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading