B21, China Town Mall, Midrand

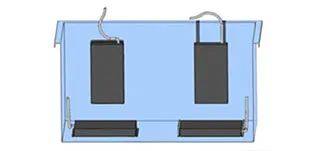

industrial ultrasonic cleaner ultrasonic cleaner automotive ultrasonic cleaner removing oil

- Section : Machinery

- Category : Industrial Ultrasonic Cleaners

- SKU : 1600801796285

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is an industrial ultrasonic cleaner?

An industrial ultrasonic cleaner is a cleaning device that uses ultrasonic waves to create high-frequency sound waves in a cleaning solution, effectively removing dirt, grease, and other contaminants from automotive parts.

2. How does the ultrasonic cleaning process work?

The ultrasonic cleaning process works by generating high-frequency sound waves that create microscopic bubbles in the cleaning solution. These bubbles implode, producing strong cleaning action that dislodges contaminants from surfaces.

3. What types of automotive parts can be cleaned with this ultrasonic cleaner?

This ultrasonic cleaner is designed for various automotive parts, including injectors, carburetors, and other metal components that require thorough cleaning to remove oil and grease.

4. What is the effective tank capacity of the KER-2400 model?

The KER-2400 model has an effective tank capacity of 112 liters (29.6 gallons), making it suitable for cleaning medium-sized automotive parts.

5. Is the operation of the ultrasonic cleaner user-friendly?

Yes, the ultrasonic cleaner features a one-touch operation system that minimizes manual input, making it easy to use for both experienced and novice operators.

6. Can the cleaning parameters be customized?

Yes, the cleaning parameters can be easily set and customized using the PLC and HMI control system, allowing for tailored cleaning cycles based on the specific needs of the parts being cleaned.

7. What safety features does this ultrasonic cleaner have?

The ultrasonic cleaner is equipped with an emergency stop button, fault and maintenance reminders, and a liquid level protector to ensure safe operation.

8. Does the ultrasonic cleaner come with a filtration system?

Yes, the ultrasonic cleaner includes a circulation and filtration system that helps maintain the cleanliness of the cleaning solution and prolongs its effectiveness.

9. What are the dimensions of the KER-6000 model?

The KER-6000 model has overall dimensions of 1860 x 1150 x 1180 mm, making it suitable for larger cleaning tasks.

10. Can the ultrasonic cleaner be networked for remote operation?

Yes, the ultrasonic cleaner features a networking function that allows for remote debugging and PLC program updates, enhancing its usability in industrial settings.

11. What brands are the electronic components sourced from?

The electronic components and parts used in the ultrasonic cleaner are sourced from world-famous brands, ensuring reliability and quality.

12. Is there an option for a lifting device with this cleaner?

Yes, the ultrasonic cleaner can be equipped with an optional lifting device that provides up-down-shaking movement, making it easier to remove heavy dirt and contaminants.

13. How many ultrasonic transducers does the KER-8000 model have?

The KER-8000 model has 80 ultrasonic transducers, which work together to provide efficient and thorough cleaning.

14. What is the power output of the ultrasonic cleaner?

The power output varies by model, with the KER-2400 model providing 2.4 KW, while the larger KER-12000 model can deliver up to 12.0 KW.

15. Does this ultrasonic cleaner require special cleaning solutions?

While standard ultrasonic cleaning solutions can be used, it is recommended to use specialized cleaning solutions designed for automotive parts to achieve optimal results.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading