B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

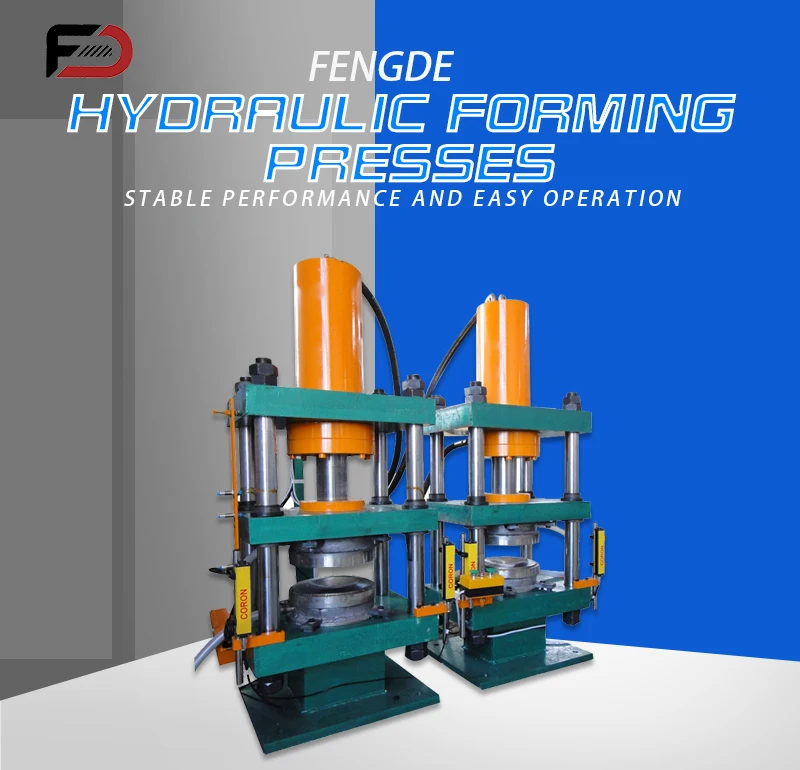

1. What is the Hydraulic Press YLJ-120 designed for?

The YLJ-120 is designed for high-performance, safe stamping of plastic compound (stamped plastic) products and similar forming operations in manufacturing environments.

2. What are the main technical specifications of the YLJ-120?

Key specs: 7.5 kW motor, ejector/maximum working force 1176 kN, hydraulic cylinder diameter 220 mm, effective working table area 510 × 450 mm, column size 80 mm, 40YCY axial piston oil pump, tandem oil cylinders, PLC/PC control, and a machine weight of about 1 ton.

3. Does the YLJ-120 support CNC control and precision operation?

Yes. The machine supports CNC/PC control for precise control of pressing cycles, positioning and repeatability, improving accuracy for complex or high-volume production.

4. Can the dimensions of the press be customized?

Yes. The YLJ-120’s size and some configuration options can be tailored to meet specific production requirements—contact sales to discuss available customization options.

5. What safety features does the YLJ-120 include?

The press is built with high safety levels including PLC/PC anti-interference electrical control, standard safety interlocks and controls, and design features that minimize operator risk. Always follow machine guarding and local safety regulations.

6. What types of materials can the YLJ-120 process?

The YLJ-120 is optimized for stamped plastic compound products. It may handle other compliant non-metallic or soft composite materials—consult the manufacturer with material examples and process requirements before use.

7. What does the hydraulic system consist of and what are its advantages?

The system uses an integrated valve block with cartridge valves, electro-hydraulic proportional valves, a 40YCY axial piston pump, tandem cylinders and a large-flow oil circuit. This reduces pressure loss, improves sealing and reliability under heavy long-term loads and provides stable, responsive control.

8. What after-sales and technical support is provided?

After the warranty period, video technical support is available. For warranty length, spare parts, service and on-site support options, contact customer service or your sales representative.

9. What are the installation requirements for the YLJ-120?

Prepare a level, load-bearing concrete foundation for the ~1 ton machine, a suitable 3-phase power supply for a 7.5 kW motor, hydraulic and cooling connections as specified, adequate ventilation and clearance for maintenance. Professional installation and commissioning are recommended.

10. How is die tooling mounted and changed on the YLJ-120?

The press uses an upper pressurizing cylinder connected to the upper die and a moving lower table for the lower die. Dies should be mounted and changed following the manufacturer’s procedures using proper lifting tools and qualified technicians to ensure alignment and safety.

11. What maintenance is required to keep the press running reliably?

Regular maintenance includes checking hydraulic fluid level/quality, replacing filters, inspecting seals and hoses, verifying valve and cylinder performance, cleaning cooling passages, lubricating moving parts, and scheduled professional inspections per the operator manual.

12. What is the expected production speed or cycle time for the YLJ-120?

Cycle time depends on stroke length, material, tooling, and process settings. The YLJ-120’s tandem cylinders and large-flow hydraulic design support fast production, but provide your process parameters to the supplier for a realistic cycle-time estimate.

13. What electrical and control features does the machine have?

Electrical control is PC/PLC-based for anti-interference, high automation and simple operation. It includes electro-hydraulic proportional valves and integrated control for precise pressure/speed profiling. Specific control panel layout and I/O can be confirmed with the manufacturer.

14. What is the difference between 'ejector force' and 'pressing force' listed for this machine?

In the provided data the 1176 kN value is listed as maximum working/ejector force. 'Pressing force' typically refers to the maximum downward forming force, while 'ejector force' refers to the force used to eject parts from the die. Clarify with the supplier which functions share this rating for your application.

15. What warranty does the YLJ-120 come with?

Warranty terms are not specified in the general description—warranty length and coverage vary by seller and region. Contact the sales representative for specific warranty details; video technical support is offered after the warranty period.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading