B21, China Town Mall, Midrand

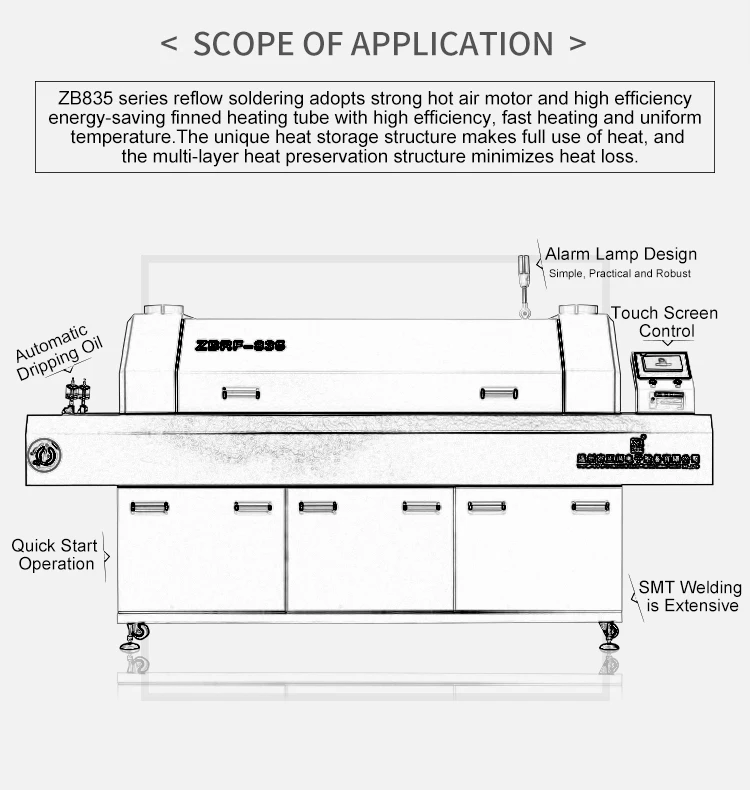

HUAQIZHENGBANG High-Efficiency Reflow Soldering Machine

- Section : Machinery

- Category : Welding Equipment

- SKU : 1600188257698

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What heating method does the HUAQIZHENGBANG High-Efficiency Reflow Soldering Machine use?

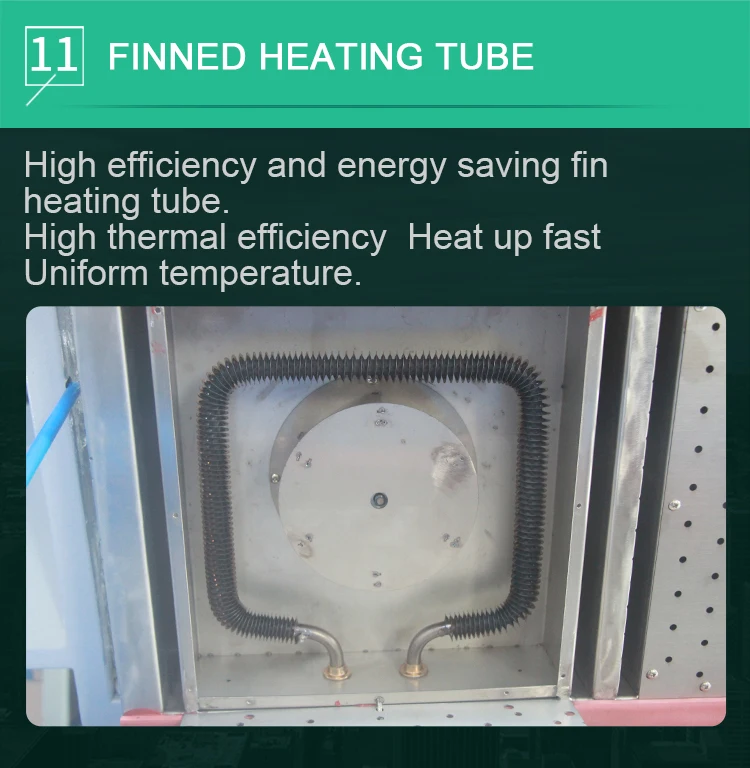

It uses a hot-air (hot-wind) heating method with 8 heating zones (4 upper and 4 lower) to provide even, controllable heat across the PCB.

2. What PCB sizes can this reflow oven handle?

The machine supports PCBs up to 280 mm wide and up to 350 mm long, making it suitable for a wide range of small to medium boards.

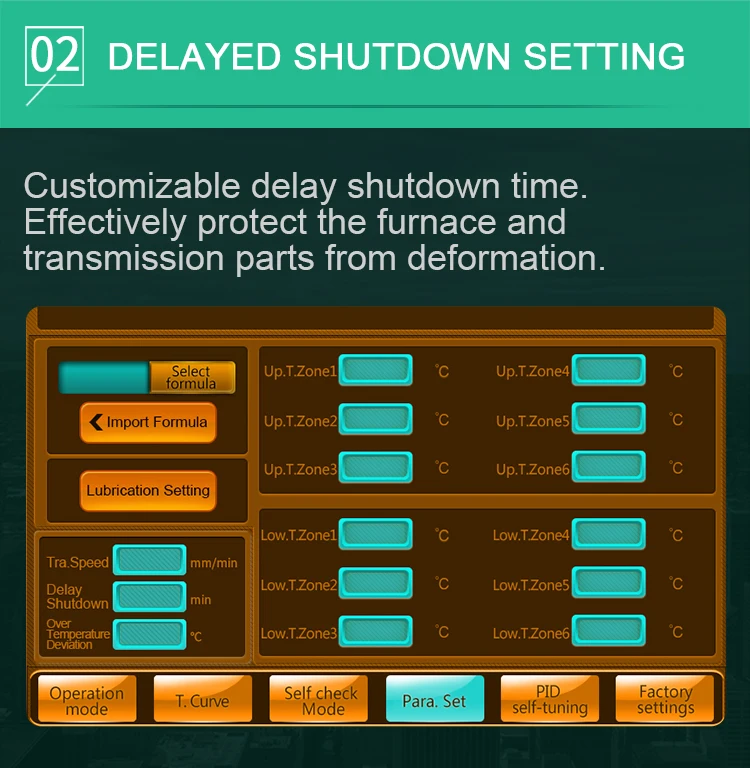

3. What is the adjustable transport (conveyor) speed range?

Transport speed is adjustable from 160 to 1350 mm/min via analog speed control to match different soldering profiles and throughput needs.

4. What are the electrical and power requirements?

The machine requires three-phase five-wire 380V ±10% at 50Hz. Product literature lists rated power in different places (15 kW in the overview; model specs show 11 kW starting power and 3.5 kW working power). Actual consumption depends on settings and profile — confirm the exact model specification and ensure your facility can handle inrush and running load.

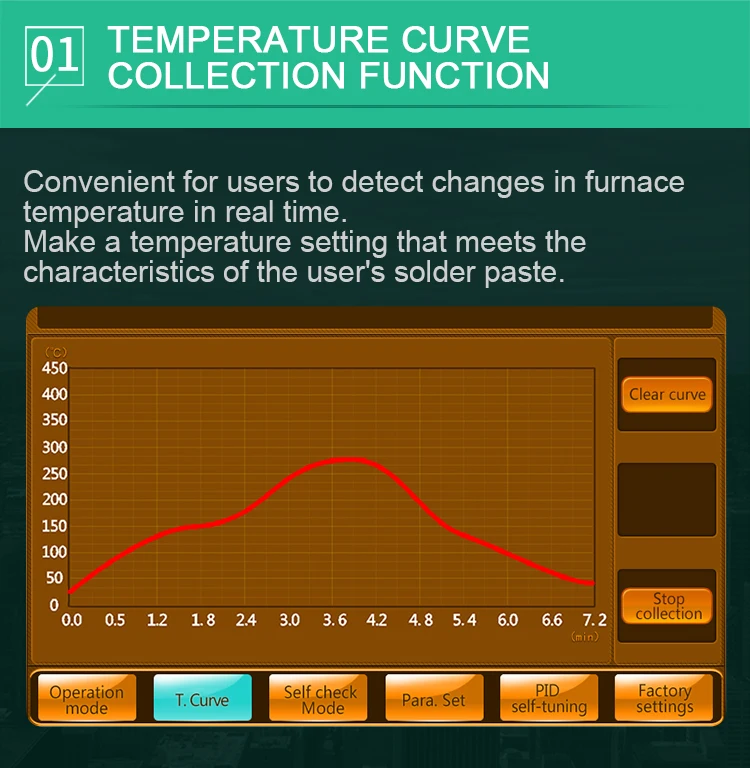

5. What temperature range and control system does it use?

Temperature control range is up to 400°C (from room temperature to 400°C). The oven uses a PID closed-loop control system for precise, repeatable temperature profiles and fast, energy-efficient heating.

6. How long does the machine take to heat up and how long does a PCB pass through the oven?

Typical warm-up time is about 20 minutes. The transit (pass-through) time for a board is typically 3.5–5.5 minutes, depending on transport speed and profile settings.

7. What type of cooling does the oven provide?

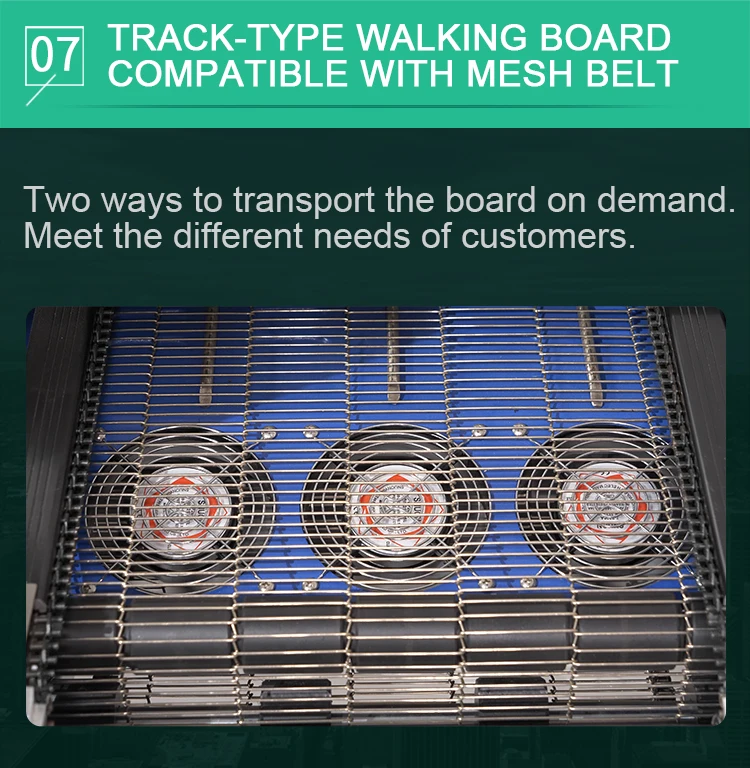

The unit includes two natural air cooling zones. For faster or controlled active cooling requirements, external or additional forced-air cooling solutions may be considered.

8. Can the conveyor direction be changed?

Yes — the conveyor can operate Left → Right or Right → Left, depending on production line layout and configuration.

9. What are the conveyor dimensions and belt height?

The net conveyor belt width is 300 mm. The recommended maximum PCB width is 280 mm and the conveyor height is approximately 900 ±20 mm. The heating zone length is 1400 mm.

10. Does the machine support lead-free soldering?

Yes. With PID temperature control and a maximum temperature up to 400°C, the oven is suitable for lead-free (RoHS) soldering processes and profiles.

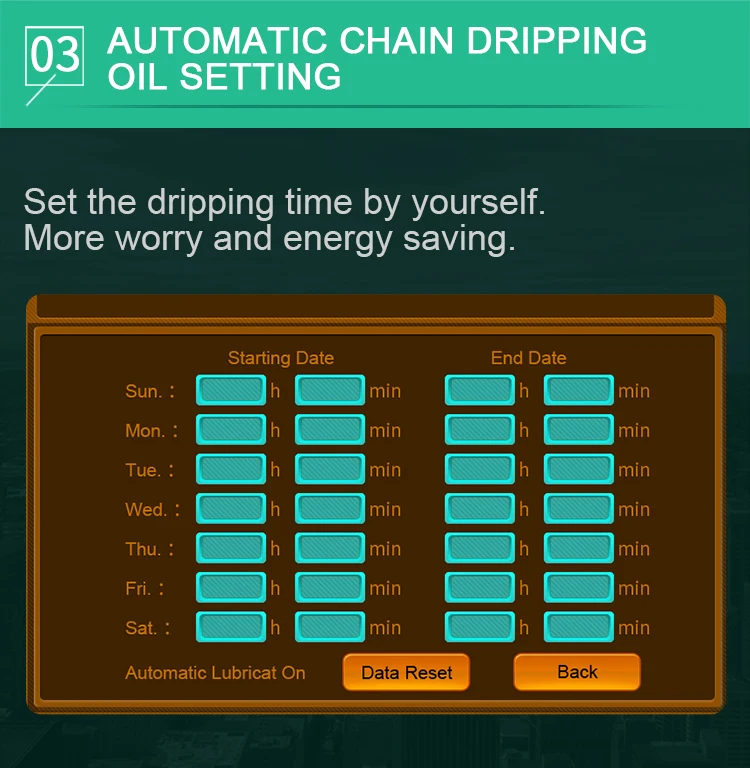

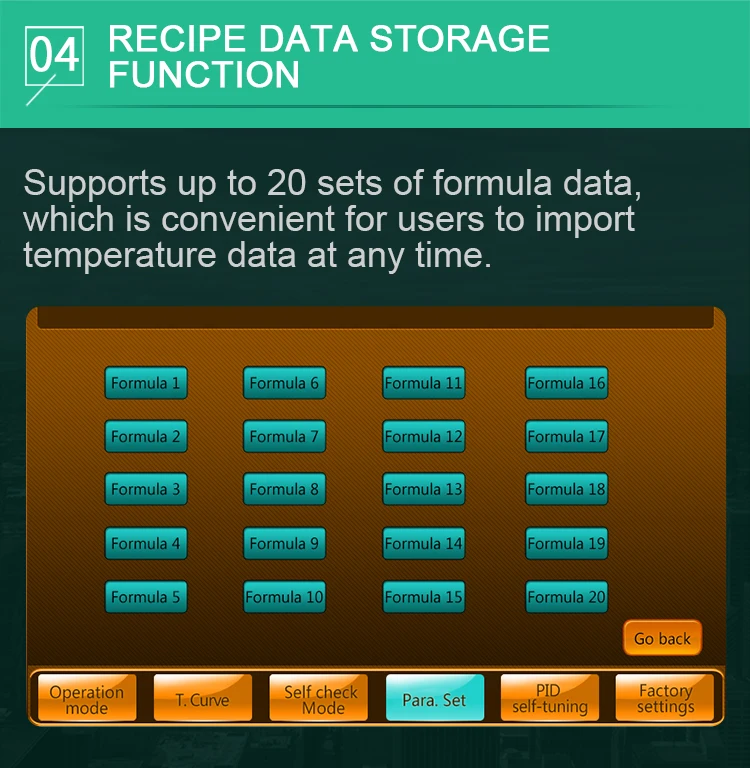

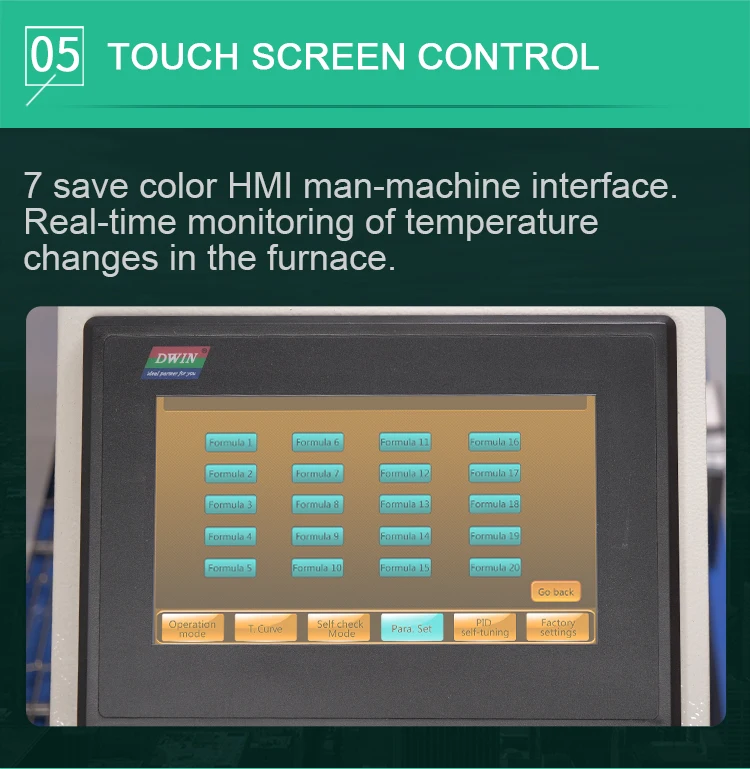

11. What automation and convenience features does it include?

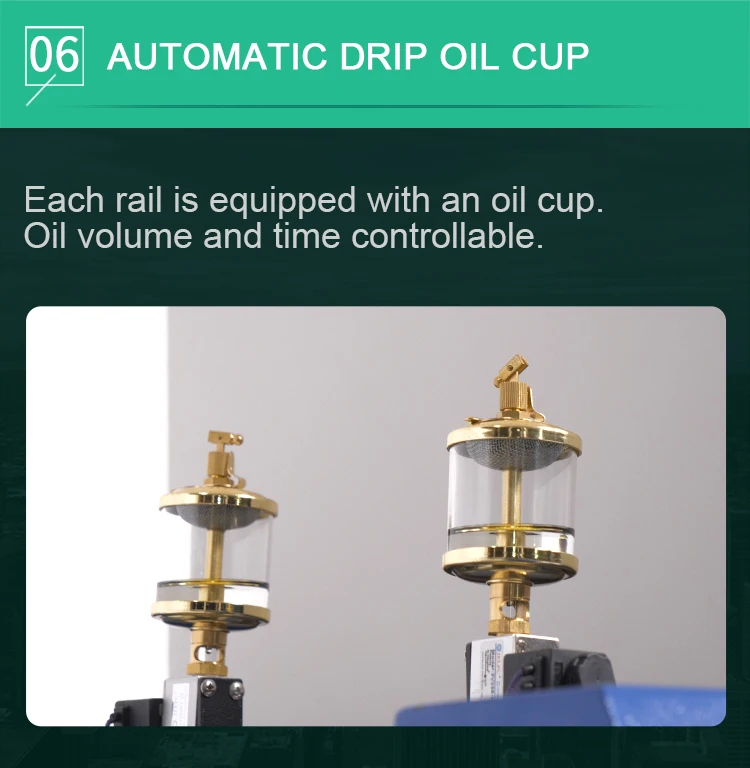

Features include timing automatic chain dripping (an automated timed chain-lubrication/drip system to maintain conveyor performance), drawer-type heater modules for easy replacement, and external controls for temperature and belt speed for convenient operation and monitoring.

12. What certifications and warranty are provided?

The machine is CE certified and comes with a 1-year warranty. After-warranty technical support is available via video support from the supplier.

13. What are the machine dimensions and weight? How much floor space is needed?

Listed dimensions vary by documentation — example outline sizes include 2720 × 820 × 1360 mm (weight ~450 kg) and 2440 × 680 × 1200 mm (net weight ~350 kg). Exact size and shipping/crate footprint depend on the model and options, so confirm the specific model dimensions before planning installation.

14. What routine maintenance is required?

Routine maintenance includes keeping the interior and ventilation paths clean, inspecting and cleaning the conveyor belt, lubricating moving parts (the automatic chain drip helps with this), and checking heater modules and electrical connections. Replace heater elements, belts or worn parts as they show signs of wear. Follow the supplier’s maintenance schedule in the manual.

15. How do I estimate production throughput with this oven?

Throughput depends on board size, spacing, and chosen transport speed. The oven’s typical transit time is 3.5–5.5 minutes per pass — increasing belt speed reduces transit time but requires profile adjustments. For continuous production, calculate cycle time based on your board length + spacing and selected mm/min speed to estimate pieces per hour.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading