B21, China Town Mall, Midrand

High Precision Nipple Small Hydraulic Three Axis Thread Rolling Knurling Machine With Reliable Motor and Engine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1601042074196

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the High Precision Nipple Hydraulic Three Axis Thread Rolling Machine?

The main function of this machine is to produce plastic deformation of metal under pressure to create threads on workpieces using three rolling wheels.

2. What types of workpieces is this machine suitable for?

This machine is especially suitable for thin-walled workpieces and other heterogeneous materials.

3. What is the angle between the rolling wheels?

The three rolling wheels are positioned at an angle of 120 degrees to effectively process the thread.

4. How does the heat treatment of the rotating shaft benefit the machine?

The heat treatment of the rotating shaft reduces noise and enhances its robustness, contributing to better performance and longevity.

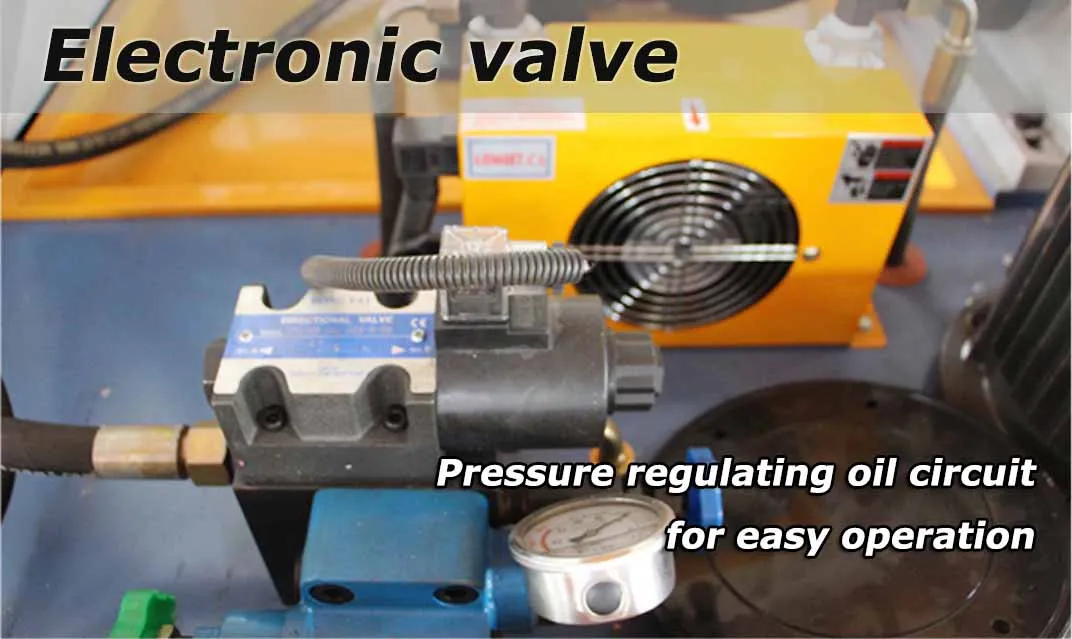

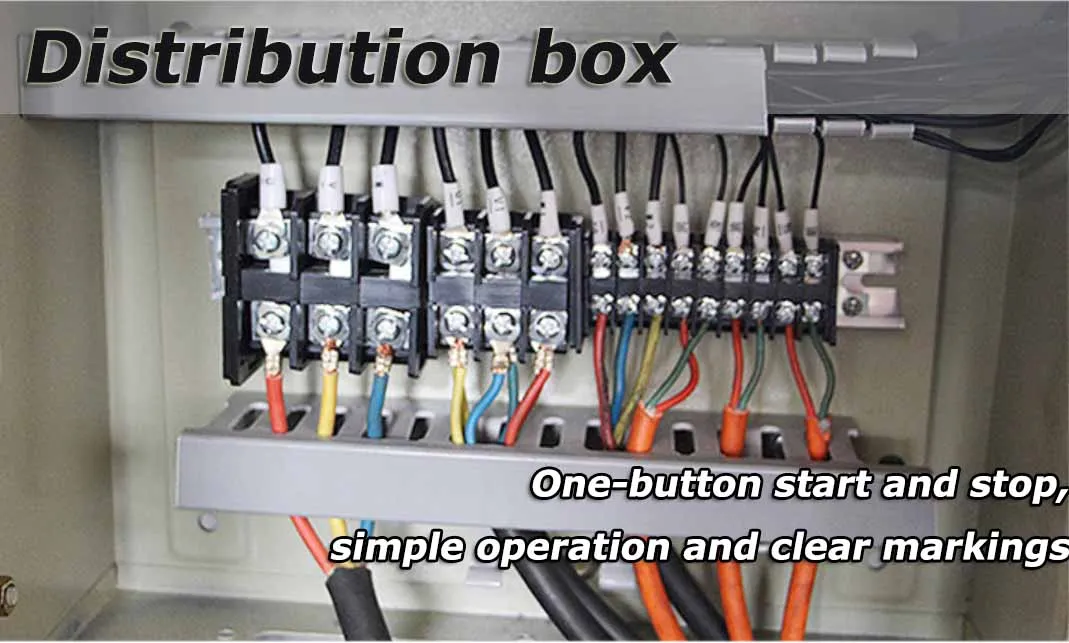

5. Is the machine easy to operate?

Yes, the machine is designed for ease of operation and features both fast and slow functions for stability and efficiency.

6. What is the structure of the machine like?

The machine has a compact structure with strong rigidity due to its cast steel fuselage, making it durable and reliable.

7. Does the machine require a lot of maintenance?

The machine is easy to maintain and repair, with a built-in fuel tank that occupies less space, which simplifies upkeep.

8. What kind of motor does this machine use?

The machine is equipped with a reliable motor that ensures consistent performance and efficiency.

9. What are the dimensions of the machine?

The specific dimensions are not provided in the description, but it is designed to be compact and space-efficient.

10. Can this machine be used for large scale production?

Yes, the efficient design and operational capabilities make it suitable for larger scale production needs, especially for thin-walled components.

11. What safety features does the machine have?

While specific safety features are not mentioned, it is advisable to follow standard safety protocols when operating any hydraulic machinery.

12. What materials can be processed with this machine?

The machine is primarily designed for metal workpieces, especially those that are thin-walled or heterogeneous.

13. Is there a warranty for the machine?

Warranty information is not provided in the description; please check with the manufacturer or supplier for warranty details.

14. What is the power consumption of this machine?

The power consumption details are not specified in the description. You may need to refer to the product manual or consult the supplier for this information.

15. How does the three-axis feature improve the threading process?

The three-axis feature allows for more versatile and precise threading, accommodating various workpiece shapes and sizes effectively.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading