B21, China Town Mall, Midrand

High Performance Fully Automatic Lathe Slant Bed Cnc Lathe Machine Slant Bed Cnc Lathe

- Section : Machinery

- Category : CNC industrial Machinery

- SKU : 1601200997921

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 18 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum speed of the High Performance Fully Automatic Lathe?

The maximum speed varies based on the specific model and configuration, but this lathe is designed for high-speed operations, ensuring optimal machining efficiency.

2. What materials can be machined using this CNC lathe?

This CNC lathe can machine a variety of materials including metals, plastics, and composites, making it suitable for diverse applications.

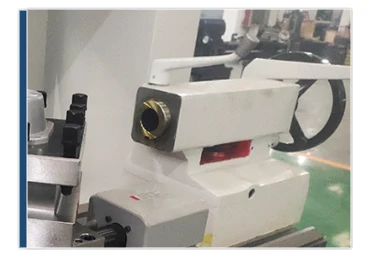

3. What type of operating system does this CNC lathe use?

The machine uses an original operating system that supports servo motors and drives, allowing for customizable operating parameters.

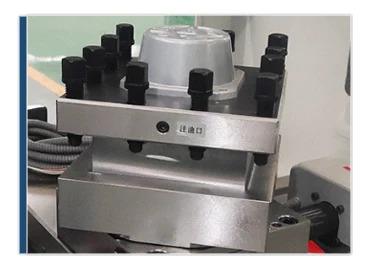

4. How does the self-lubrication system work?

The self-lubrication system automatically lubricates the machine at timed intervals and in precise quantities, eliminating the need for manual refueling.

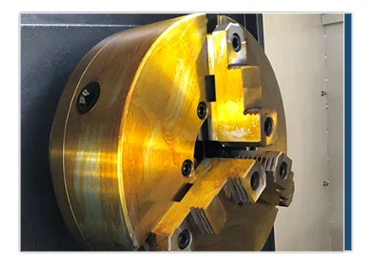

5. What is the clamping range of the standard three jaw chuck?

The standard three jaw chuck offers a large clamping range, ensuring versatility for various workpiece sizes.

6. Is the CNC lathe suitable for high-precision machining?

Yes, this CNC lathe is designed for high-precision machining, with high position accuracy and smooth chip removal.

7. What is the significance of the slant bed design?

The slant bed design enhances stability, improves chip removal, and contributes to the overall precision and performance of the machine.

8. How durable is the machine's casting structure?

The whole casting structure is made from high-strength materials, ensuring a long service life and stability over time.

9. Can I customize the tool holder options?

Yes, the machine comes with a standard heavy-duty four-station electric tool holder, and options for six-station or eight-station tool towers are available.

10. What kind of maintenance does this CNC lathe require?

Regular maintenance includes checking the self-lubrication system, inspecting the tool holders, and ensuring the operating system is updated.

11. Is training provided for operating the CNC lathe?

Yes, training resources and support are typically available to ensure users can effectively operate the CNC lathe.

12. What is the weight of the CNC lathe?

The weight of the CNC lathe can vary by model, but it is designed to have a low center of gravity for stability during operation.

13. Are there any safety features included with the CNC lathe?

Yes, the machine includes several safety features designed to protect the operator and ensure safe operation.

14. What is the warranty period for the CNC lathe?

The warranty period varies by manufacturer, but typically covers a one to two-year period for parts and labor.

15. Can the CNC lathe handle large workpieces?

Yes, the CNC lathe is designed with a large clamping range and robust construction to handle a variety of workpiece sizes.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading