B21, China Town Mall, Midrand

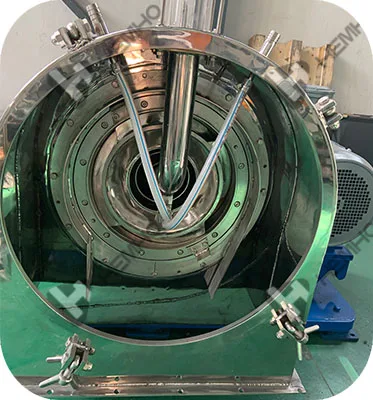

Hemho LWL250 Screening and Separation Machine

- Section : Machinery

- Category : Separation Equipment

- SKU : 1600721957208

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What industries can benefit from the Hemho LWL250 Screening and Separation Machine?

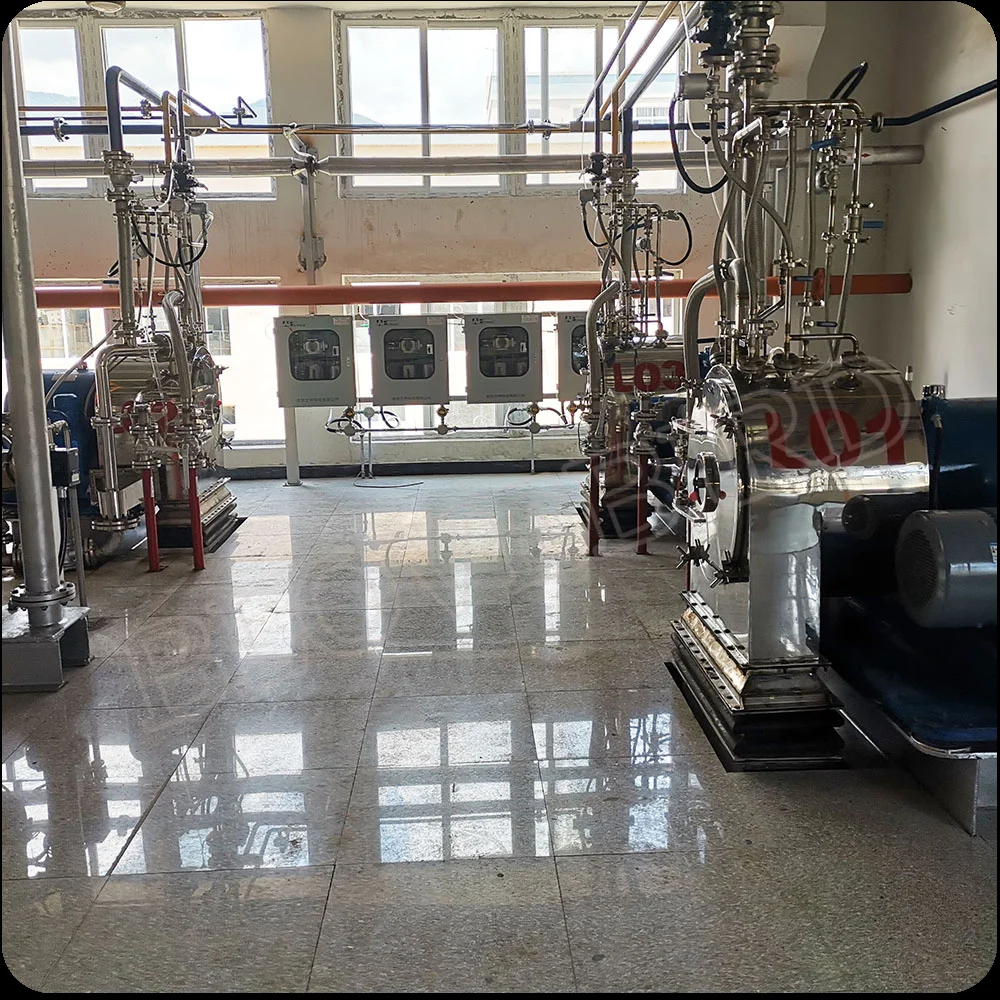

The Hemho LWL250 is suitable for various industries, including chemical, food, salt, mining, and pharmaceutical, where reliable screening and sorting solutions are required.

2. What materials can the Hemho LWL250 effectively separate?

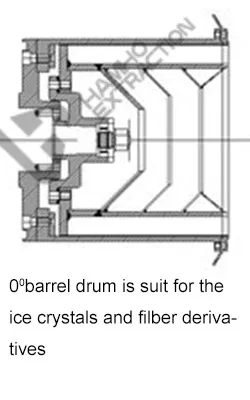

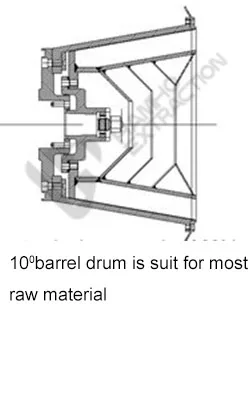

The machine is designed to handle materials with larger particle sizes, such as fibers, plastic particles, and various crystals, without strict requirements for particle damage.

3. What are the key features of the Hemho LWL250?

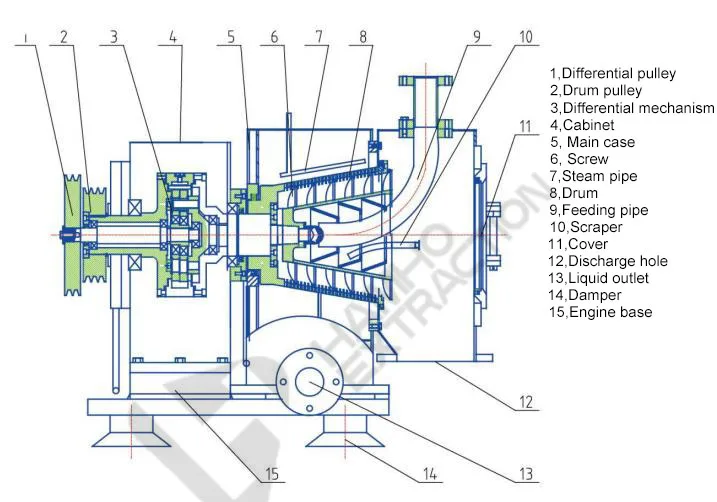

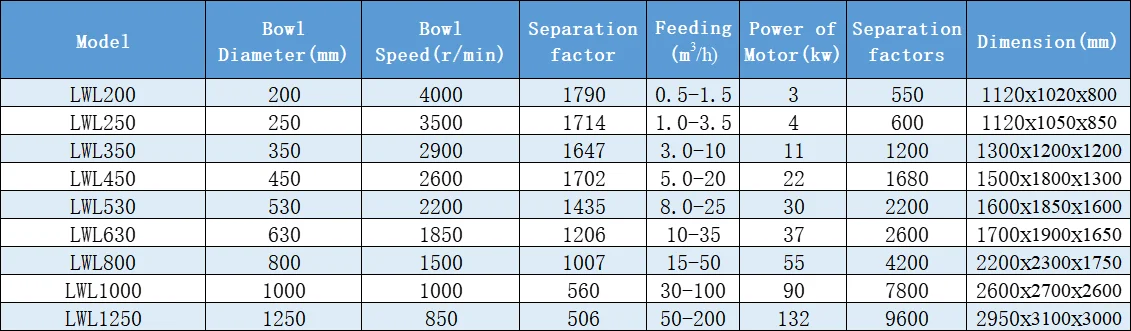

Key features include efficient functionality for screening and separation, durable construction from high-quality stainless steel, a powerful 4 kW motor, a high separation factor of 600, and a continuous operation capability.

4. What is the feed rate capacity of the Hemho LWL250?

The Hemho LWL250 can handle a feed rate of 0.5 to 1.5 cubic meters per hour.

5. Is the Hemho LWL250 suitable for continuous operation?

Yes, the Hemho LWL250 is designed for continuous operation, allowing it to function without interruption during screening and separation tasks.

6. What type of discharge system does the Hemho LWL250 feature?

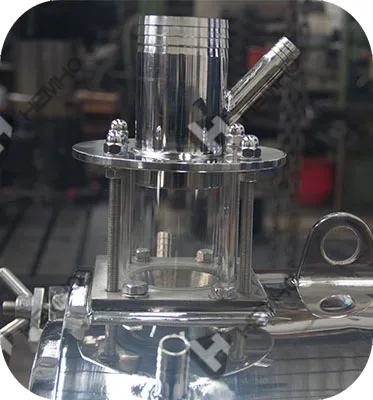

The Hemho LWL250 includes a spiral screw discharge system, ensuring efficient removal of separated materials and minimizing downtime.

7. How does the Hemho LWL250 ensure durability?

The machine is constructed from high-quality 304/316L stainless steel, which resists rust and wear, enhancing its durability for long-term use.

8. What is the motor specification of the Hemho LWL250?

The Hemho LWL250 is equipped with a 4 kW motor that operates at a speed of 3500 RPM, providing powerful performance for effective material separation.

9. Can the dimensions of the Hemho LWL250 be adjusted?

Yes, the Hemho LWL250 offers variable dimensions, making it adaptable to different operational needs.

10. What safety features are included in the Hemho LWL250?

The machine includes safety features such as speed detection, over-vibration protection, motor overload and overheat protection, and spiral zero differential protection.

11. What maintenance is required for the Hemho LWL250?

Regular maintenance includes checking the lubrication system, ensuring proper sealing of bearings, and inspecting the filter screens for wear and tear.

12. What is the separation factor of the Hemho LWL250?

The Hemho LWL250 features a separation factor of 600, allowing for precise sorting and separation of materials.

13. Does the Hemho LWL250 come with a warranty?

Warranty details vary by supplier. It is recommended to check with your vendor for specific warranty information regarding the Hemho LWL250.

14. What improvements have been made in the Hemho LWL250 design?

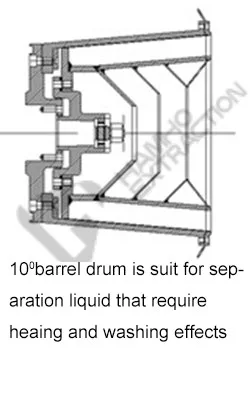

Improvements include enhanced feeding pipe distribution for stability, an upgraded lubrication system, better bearing sealing, and a treated drum spiral for durability.

15. Is the Hemho LWL250 suitable for high viscosity materials?

Yes, for high viscosity materials, a hydraulic differential can be used with the Hemho LWL250, ensuring stable and reliable operation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading