B21, China Town Mall, Midrand

Heating Overwrapping Sealing Shrink Machine for Carton - CHENGQI

- Section : Machinery

- Category : Wrapping Machines

- SKU : 62120585495

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Heating Overwrapping Sealing Shrink Machine for Carton - CHENGQI used for?

This automatic machine is designed to wrap, sleeve-seal and shrink PE film around cartons and larger items. It is suitable for apparel, beverages, food, chemicals, machinery, hardware, textiles and other industries that require secure carton packaging.

2. What are the main components and models included in this packaging line?

The solution comprises the TFZ-8040 fully automatic straight-feeding sleeve sealer (sealing station) and the BS6040 shrink tunnel (heat tunnel) for final shrink wrapping and finishing.

3. What are the machine dimensions and weight?

The sealing machine overall dimension is 1700 mm (L) × 1350 mm (W) × 2200 mm (H) and weighs about 350 kg. The shrink tunnel size is L1800 × W600 × H400 mm; the combined package size is approximately L2850 × W1050 × H1900 mm with gross/net weights around 620/560 kg.

4. What power and utilities does the machine require?

The sleeve sealer requires 380V/50–60Hz, 2 kW. The shrink tunnel requires AC 380V 3-phase 50/60 Hz and 20 kW. Compressed air at approximately 6 kgf/cm² is also required for pneumatic components.

5. What packaging sizes and speeds can it handle?

Packing size up to W ≤ 650 mm and H ≤ 380 mm; sealing width up to 800 mm. Packaging speed depends on product size but typically 10–15 pcs/min. Shrink film max width ≤ 750 mm, max roll weight ≤ 35 kg and max film depth ≤ 250 mm.

6. What film types are compatible with this machine?

The machine is designed to work with PE (polyethylene) single-layer shrink film (sleeve type). For optimal results use quality PE shrink film within the specified width and roll weight limits.

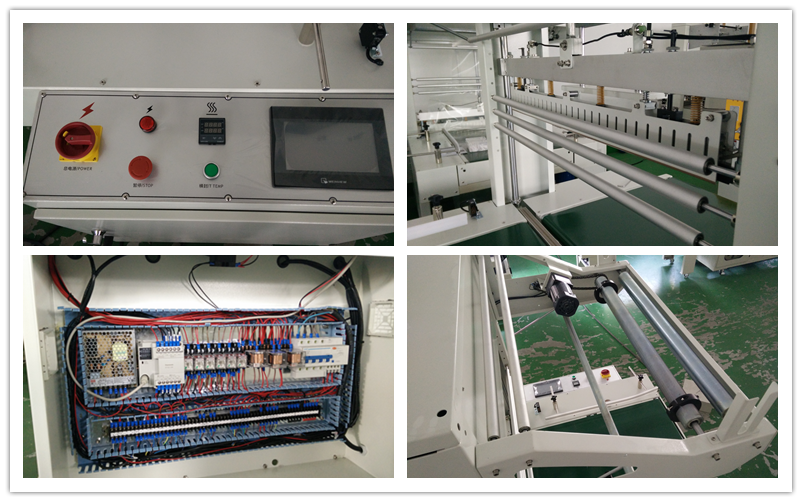

7. How is the machine controlled and how easy is it to operate?

Control is handled by a Panasonic PLC and a WEINVIEW 7-inch HMI (man–machine interface) for simple operation. The machine supports automatic and manual modes that can be switched as needed.

8. Can this machine be integrated into an existing production line for unmanned operation?

Yes. The TFZ-8040 is designed with straight in/out feeding and supports production-line integration to realize unmanned operation when connected to upstream/downstream equipment.

9. What safety and protection features are included?

Sealing blades are made of special steel with Daikin Teflon coating to prevent sticking and high-temperature damage. The sealing blade has an automatic protection function to prevent accidental cutting. The unit also includes imported photoelectric sensors for accurate positioning and a pressure device to stabilize light products during processing.

10. What maintenance and consumables should I expect?

Regular maintenance includes cleaning and inspection of the sealing knife (Teflon-coated), checking sensors, conveyor belts, and heating elements. Consumables primarily include PE shrink film and occasional replacement parts for wear items such as the sealing blade or Teflon tape.

11. What after-sales support and quality assurance are provided?

Chengqi provides online support, video technical assistance and free spare parts as part of after-sales service. Each machine comes with a machinery test report and video outgoing inspection to ensure quality before shipping.

12. Can the machine be customized for different carton sizes or special requirements?

Yes. The machine can be customized to meet specific packaging requirements such as modified table heights, conveyor configurations or film handling options. Contact the supplier with your product dimensions and requirements for a quotation.

13. What are common troubleshooting steps for poor sealing or uneven shrinking?

Check that you are using the correct PE film and that film width and tension are properly set. Verify sealing temperature and dwell time, inspect the Teflon-coated sealing blade for wear, ensure photoelectric sensors are aligned, and confirm shrink tunnel temperature and conveyor speed are correctly adjusted.

14. Is operator training and installation included?

Provided after-sales support includes video technical assistance and remote support. On-site installation, commissioning and training availability vary by supplier and region—please contact Chengqi or your local distributor for details and quotes.

15. What warranty or guarantee comes with the machine?

Specific warranty terms are determined by the seller or distributor. The machine is supplied with a machinery test report and outgoing inspection video to verify performance; contact Chengqi or your sales representative for warranty details and service agreements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading