B21, China Town Mall, Midrand

Grain Dryer in Maize Soybeans Drying Equipment Model XTY10

- Section : Machinery

- Category : Agriculture Machinery

- SKU : 1600840468887

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

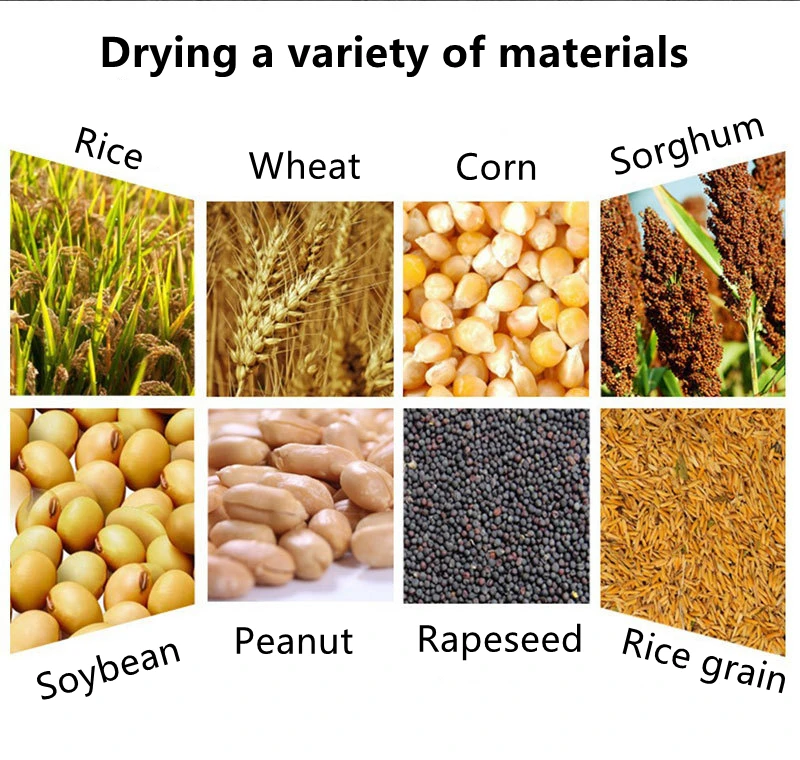

1. What crops can this Grain Dryer be used for?

It is suitable for drying corn, maize, soybeans, wheat, rice and other small grains — especially rice, where it produces less broken rice, whiter color and improved quality.

2. What drying capacities and power options are available?

Models range from about 10 T/D up to 200 T/D. Example model powers include XTY10 (4.4 kW), XTY20 (9 kW), XTY30 (13 kW), XTY45 (15.5 kW), XTY60 (16.5 kW), XTY80 (28 kW), XTY120 (33 kW) and XTY200 (49.5 kW).

3. Which heat sources are compatible with this dryer?

Multiple heat sources are supported: electric, diesel, methanol, natural gas, steam and coal. The machine uses indirect heating, so the heat source does not contact the grain.

4. How does the dryer heat the grain and is there any contamination risk?

The dryer uses indirect heating (for example a high-efficiency coal-burning heater) so combustion gases do not mix with the grain. This prevents direct contamination of the grain; environmental emissions depend on the chosen heat source and local controls.

5. What energy efficiency or fuel consumption can I expect?

The unit is designed for energy saving. As an example, one configuration can dry about 3.5 tons of wheat per hour using roughly 30 kg coal plus about 8 kW of installed electrical power. Actual consumption depends on grain type, initial moisture, ambient conditions and model.

6. Is the dryer easy to operate and control?

Yes — it features automatic temperature control and a digital display to monitor and adjust drying parameters, making operation straightforward even for less-experienced operators.

7. How easy is installation and transport?

The dryer has a split structure for easier shipment and on-site installation. It is designed for good mobility and can be disassembled for transport and reassembled at the site.

8. Can this product be customized or OEM supplied?

Yes. OEM/custom configurations are available to meet client requirements — contact the manufacturer or supplier with your specs for customized design and quoting.

9. How much moisture reduction can I expect in one pass?

The machine is engineered for significant moisture release; many grains can reach a safe storage moisture level in a single drying pass depending on initial moisture content and model capacity.

10. What routine maintenance is required?

Regular maintenance includes cleaning air inlets and dust, checking and calibrating temperature sensors and controls, inspecting heaters/heat exchangers, lubricating moving parts, and replacing worn belts or seals per the supplier's maintenance schedule.

11. Are spare parts and after-sales support available?

Yes. Spare parts and after-sales support are provided by the manufacturer or dealer. Contact your supplier for specifics on parts availability, lead times and warranty terms.

12. What safety considerations should I follow?

Follow local safety and fire codes for fuel systems, ensure proper ventilation for combustion fuels, train operators on controls and emergency shutdown procedures, and perform routine inspections to prevent dust accumulation and mechanical faults.

13. Will the dryer reduce broken/grain damage?

Yes. The product description highlights structural improvements and gentle indirect heating that help reduce broken rice and grain damage while maintaining good color and quality.

14. How do I choose the right model for my needs?

Choose based on your target daily throughput (T/D), the types of grain you dry, available heat source, and available power. Contact the supplier with your throughput goal, typical moisture in/out, and fuel options for a recommended model and configuration.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading