B21, China Town Mall, Midrand

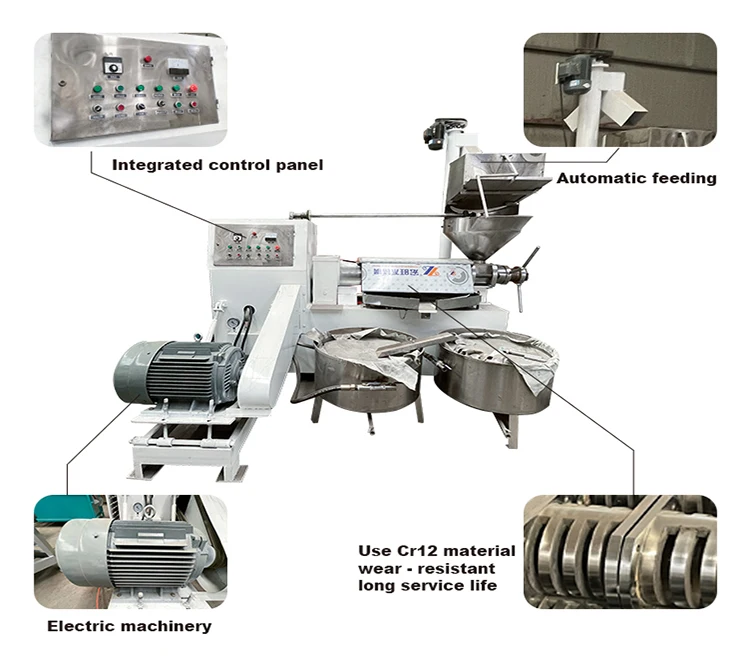

Fully automatic screw peanut 6yl-70 coffee bean expeller cold pressed virgin coconut oil extraction machine sldb

Model:

- Section : Machinery

- Category : Extractors

- SKU : 996930201822

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 18 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Fully automatic screw peanut 6yl-70 coffee bean expeller used for?

It is an automatic screw oil press designed to extract vegetable oils (cold or hot) from seeds and nuts such as peanut, soybean, sunflower, coconut, olive, sesame, rapeseed, flax, tea seed, walnut, corn germ, rice bran and similar oil-bearing materials.

2. Which feedstocks (raw materials) are compatible with this machine?

Compatible materials include peanuts, soybeans, sunflower seeds, coconut, olives, sesame, rapeseed, flax seed, camellia, cottonseed, cashew, hemp seed, corn germ, rice bran, safflower seed and seeds like hippophae rhamnoides. Hard shells or very large kernels may require pre-processing (dehulling or crushing).

3. What does 'fully automatic' mean for this press?

Fully automatic means the machine integrates electric control, automatic heating, automatic material feed/adjustment and continuous pressing so the process from feeding to oil discharge is largely automatic—usually operated by 1–2 people.

4. What production capacities and models are available?

Models range from small to large: 6YL-60 (30–60 kg/h), 6YL-70 (50–80 kg/h), 6YL-80 (80–130 kg/h), 6YL-100 (140–280 kg/h), 6YL-125 (350–400 kg/h) and 6YL-150 (350–450 kg/h). Choose by your hourly throughput needs and raw material.

5. What are the power and main electrical components?

Motor power varies by model from about 2.2 kW to 22 kW. The machine also includes an oil pump (0.55–2.5 kW range) and heaters (0.9–4.5 kW range) depending on model. Confirm required voltage and phase with the supplier for your region.

6. Does the machine do cold pressing or hot pressing?

It supports both. The unit has a heating element for hot pressing (higher yield) and can be operated without heating for cold-pressed (virgin) oil that retains more flavor and nutrients. Choose method based on product requirements.

7. What oil yield and residual oil-in-cake can I expect?

Yield depends on material and pre-processing. The machine is designed to leave less than about 6% oil in the cake when operated properly; actual yield varies by seed type and moisture/content preparation.

8. What pre-processing is required for seeds before pressing?

Seeds should be clean, free of stones/impurities, and have appropriate size and moisture. Hard shells often need shelling; large seeds may require crushing or flaking. Proper pre-treatment improves yield and extends machine life.

9. What does the vacuum oil filter do and is it included?

The vacuum oil filter (part of the machine) helps remove fine particulates and water from extracted oil through vacuum filtration, improving clarity and stability. The described machine includes vacuum filtration components as part of the system.

10. How much space and how many operators are needed?

Typical small installations need about 10–20 square meters. The machine is easy to operate and generally requires 1–2 operators for continuous production (feeding, monitoring, and oil collection).

11. What routine maintenance is required?

Regular maintenance includes cleaning the screw and press chamber after use, checking/adjusting belt tension and gearbox oil, inspecting heaters and pumps, replacing worn parts (screws, rings, gaskets) and keeping the vacuum filter clean. Follow the user manual schedule.

12. What is the quality of oil produced and does it need further processing?

Cold-pressed oil can be considered virgin/edible but may contain fine solids or moisture; further filtration, settling or centrifugation improves clarity and shelf life. Hot-pressed oil typically yields more and may need less settling but filtration is still recommended.

13. What can I do with the pressed cake (meal)?

Press cake (meal) is commonly used as animal feed, organic fertilizer, or can be further processed (solvent extraction for residual oil). Nutritional value depends on the seed and degree of oil extraction.

14. What are the machine dimensions and weight?

Dimensions and weights vary by model. As examples from the series: smaller models measure about 1.2×0.78×1.1 m and weigh ~220 kg; larger models can be up to 2.5×1.75×2 m and weigh 1,500 kg. Check the specific model datasheet for exact figures.

15. Is there warranty, installation support or operator training?

Warranty, installation and training policies vary by supplier. Most manufacturers provide a basic warranty, on-site installation or remote guidance and operator training—confirm terms, spare parts availability and after-sales support with the vendor before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading