B21, China Town Mall, Midrand

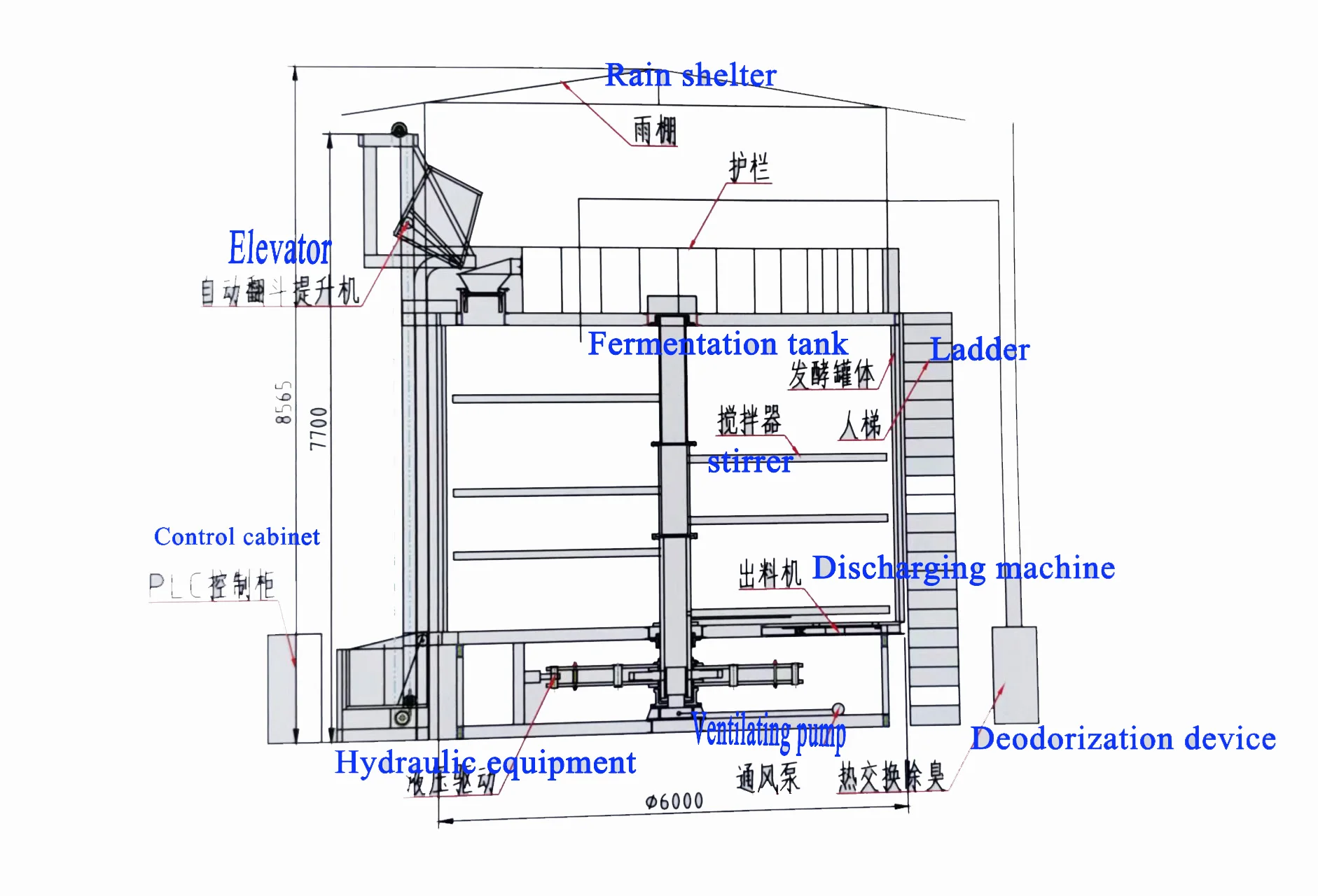

Full automatic Organic Compost Production equipment Fertilizer granule making machine

- Section : Machinery

- Category : Compost Making Machines

- SKU : 1601124686204

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of organic waste can be processed with this machine?

The Fertilizer Granule Making Machine can process a variety of organic wastes, including livestock and poultry manure, making it suitable for farms and waste treatment operations.

2. What is the production capacity of the Fertilizer Granule Making Machine?

This machine has a production capacity of up to 6 tons of organic fertilizer per hour and can handle 5m³ of production per day.

3. Is the machine suitable for small farms?

While it is designed for high-volume production, its compact design allows for easy integration into operations, making it suitable for both small and large farms.

4. How does the automatic packing feature work?

The machine is equipped with an automatic packing system that streamlines the packaging process, reducing the need for manual labor and enhancing operational efficiency.

5. What are the energy requirements for this machine?

The Fertilizer Granule Making Machine operates on a voltage range of 380-440V and is designed to consume low energy, making it an environmentally friendly option.

6. What are the dimensions of the machine?

The machine measures 20.0x2.0x3.0 meters, which allows for a space-efficient setup in your operations.

7. How does the machine ensure high accuracy in production?

The machine is designed with precision engineering, utilizing advanced components to ensure consistent and high-quality production of organic fertilizer granules.

8. Can this machine be used for waste treatment in poultry farms?

Yes, it is particularly effective for treating animal manure in poultry farms and is essential for efficient waste management in such operations.

9. What is the maintenance requirement for this machine?

Regular maintenance is recommended to ensure optimal performance, which includes checking the mechanical components and cleaning the system to prevent clogs.

10. What is the warranty period for this machinery?

The warranty period may vary by manufacturer; it is advisable to check the specific terms provided by the seller at the time of purchase.

11. Is training provided for operating the machine?

Many suppliers offer training and support for operating the Fertilizer Granule Making Machine, ensuring that users can optimize its functionality.

12. What are the benefits of using organic fertilizer produced by this machine?

Organic fertilizers improve soil fertility, enhance plant growth, and contribute to sustainable agricultural practices, reducing reliance on chemical fertilizers.

13. Can the machine handle high humidity organic waste?

Yes, the Fertilizer Granule Making Machine is designed to efficiently process high humidity organic materials, making it suitable for various types of organic waste.

14. Are there any specific safety features included in the machine?

The machine includes safety features such as emergency shut-off mechanisms and protective covers to ensure safe operation during production.

15. What materials are used in the construction of the machine?

The machine is built with durable components including a PLC, engine, gearbox, motor, and pump, ensuring long-lasting performance even under demanding conditions.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading