B21, China Town Mall, Midrand

fried chips making machine fully automatic

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600485048968

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of raw materials can be used in the fried chips making machine?

The fried chips making machine can use various raw materials including potato starch, corn starch, cassava starch, wheat flour, and corn flour.

2. What is the production capacity of the fried chips making machine?

The production capacity varies by model: the 65 Processing Line can produce 150-200 kg/h, while the 75 Processing Line can produce 250-350 kg/h.

3. How does the machine ensure the final product is crispy and not greasy?

The production process includes extruding, slaking, forming, drying, frying, and flavoring, which helps achieve a crispy texture without excessive greasiness.

4. What shapes can the fried chips be formed into?

The machine can produce various shapes such as strips, waved square sheets, diamond sheets, pillows, and triangles by changing the mould and forming machine.

5. Is the fried chips making machine environmentally friendly?

Yes, the machine is designed with efficiency in mind, utilizing low-carbon technology and eliminating the need for a boiler in the production process.

6. What is the maintenance required for the fried chips making machine?

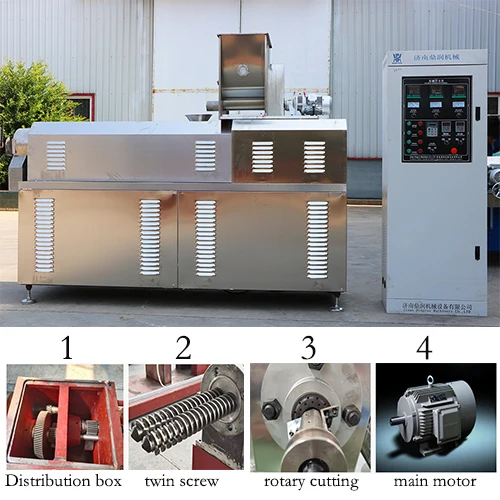

Regular cleaning and maintenance of the screw, cutter, and other components are recommended to ensure long service life and optimal performance.

7. Can the machine handle large volume production?

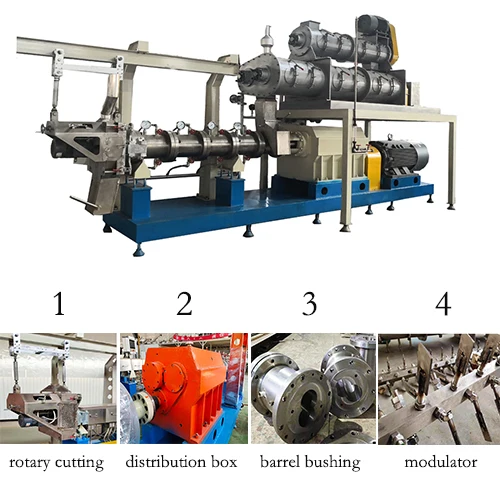

Yes, especially the wet type equipment features cantilever rotary cutting, which is suitable for large output and quick tool setting.

8. What are the dimensions of the machines?

The dimensions vary by model: the 65 Processing Line measures 18800x4500x2400 mm, and the 75 Processing Line measures 26000x5000x3500 mm.

9. How do I adjust the cutter for different shapes?

The rotary cutting system allows for easy adjustment of the cutter head, enabling you to switch between different shapes with minimal effort.

10. What kind of motor is used in the machine?

The machine is equipped with a Siemens main motor, known for its quality and long service life.

11. What is the process flow of the fried snacks production line?

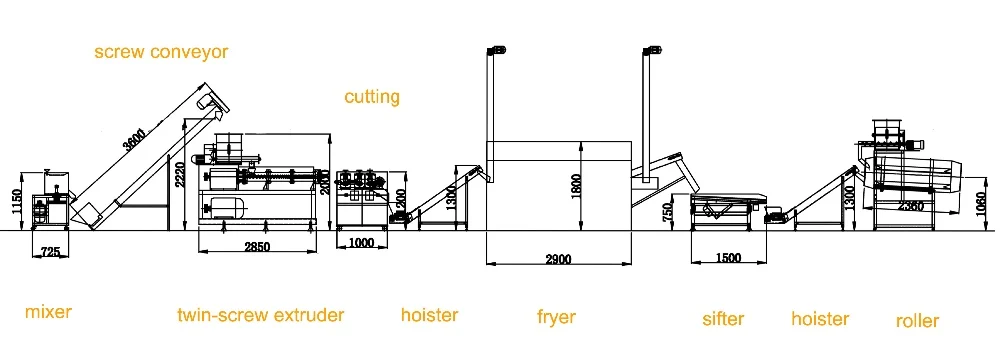

The process flow includes Mixing → Screw conveyor → Extruder → Shaping and cutting → Fryer → Deoiling → Flavoring → Cooling → Packing.

12. Is training provided for operating the machine?

Yes, training is typically provided to ensure operators understand how to use the machine effectively and safely.

13. What are the advantages of using twin-screw extrusion technology?

Twin-screw extrusion technology enhances mixing, cooking, and shaping of raw materials, leading to improved product quality and efficiency.

14. Are spare parts readily available for the machine?

Yes, spare parts are usually available, ensuring that any necessary replacements can be made quickly to minimize downtime.

15. What safety features are included in the machine?

The machine includes safety features such as emergency stop buttons, protective covers, and safety interlocks to ensure safe operation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading