B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

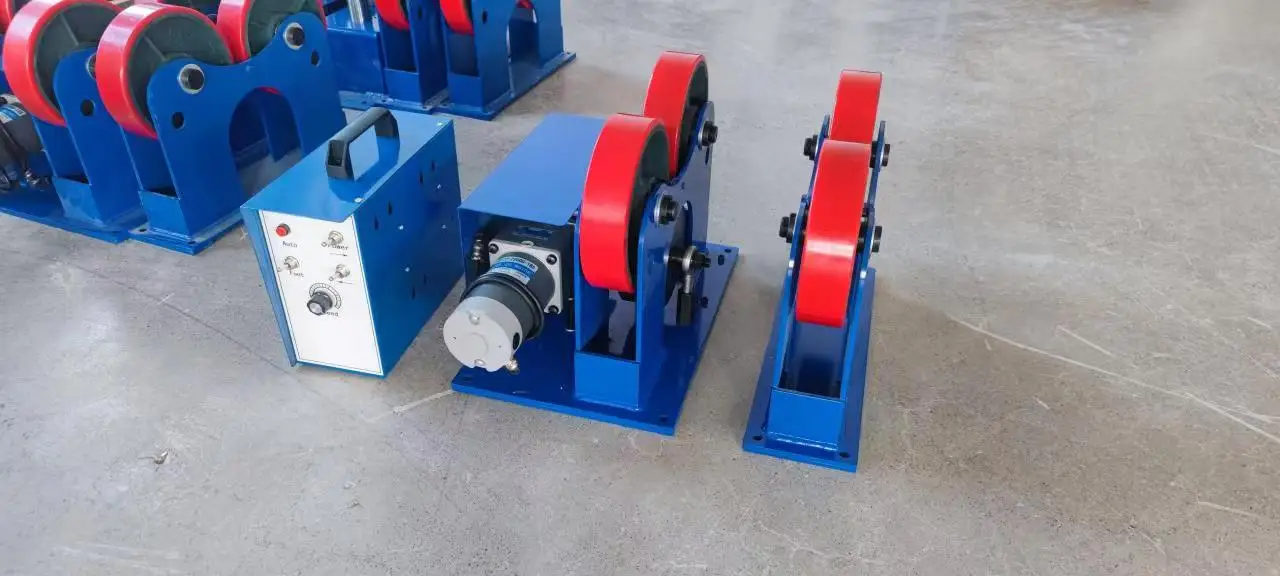

1. What is the maximum load capacity of the E-WORK Pipe Bending Machine?

The machine has a maximum capacity of 1000 kg (model XH-1T). Do not exceed this load to avoid damage or safety hazards.

2. What pipe diameters can this machine bend?

It accommodates pipe diameters from 20 mm up to 800 mm, covering a wide range of industrial piping sizes.

3. What is the adjustable rolling/line speed of the machine?

The product description lists an adjustable rolling speed range of 80–1600 mm/min. The XH-1T model specification shows a typical line speed range of 150–1100 mm/min. Check your specific unit's nameplate or manual for the exact range.

4. What motor and power requirements does it have?

The machine is equipped with a 220 V, 120 W driving motor. Ensure a stable 220 V supply and consult the manual or supplier for connection and electrical protection requirements.

5. What are the roller dimensions and material durability?

The standard rollers measure 50 mm × 250 mm and are designed for durability and precision. For applications with unusual materials or higher wear, inquire about hardened or specialty rollers.

6. How much does the machine weigh and how should it be installed?

The machine weighs approximately 95 kg. Place it on a stable, level surface and use appropriate lifting equipment or two people for positioning. Secure mounting or anchoring may be required for production use.

7. Which pipe materials can be bent with this machine?

It is suitable for many common pipe materials such as mild steel, stainless steel, copper, aluminum, and certain plastics. Performance depends on material grade, diameter and wall thickness — consult the supplier for guidance on specific materials.

8. What is the maximum pipe wall thickness the machine can bend?

Maximum wall thickness is not specified in the general description and varies with pipe diameter and material. Contact the manufacturer or supplier with your pipe specifications to confirm capability.

9. Can the machine produce tight radii and complex bends?

The machine performs rolling/section bending well for continuous curves and large radii. Very tight radii or highly complex shapes may require special tooling, multiple passes, or alternative bending methods. Consult the manufacturer for custom tooling options.

10. How do I set up the machine for different pipe diameters?

Adjust the roller positions and top/bottom guides according to the pipe diameter, set the appropriate rolling speed and pressure, secure the pipe, and perform a test pass. Follow the detailed setup procedure in the operator manual.

11. What routine maintenance is required?

Regular maintenance includes cleaning chips and debris, inspecting rollers for wear, lubricating bearings and moving parts per the manual, checking electrical connections, and verifying drive components. Schedule inspections and replace worn parts promptly.

12. What safety precautions should operators follow?

Operators should wear appropriate PPE (gloves, eye protection), keep hands and loose clothing away from moving parts, secure the pipe properly, never exceed the rated capacity, disconnect power before maintenance, and ensure only trained personnel operate the machine.

13. Are spare parts and replacement rollers available?

Spare parts and replacement rollers are commonly available through the manufacturer or authorized dealers. Contact your supplier with the model (XH-1T) and part details to order replacements.

14. Is training required to operate the E-WORK Pipe Bending Machine?

Yes. While the machine is user-friendly, proper training on setup, operation, safety, and maintenance is recommended to ensure accurate results and to prevent damage or injury.

15. What warranty and after-sales support are provided?

Warranty and after-sales support information is not included in the general product description. Contact your vendor or the manufacturer for details on warranty terms, service contracts and technical support options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading