B21, China Town Mall, Midrand

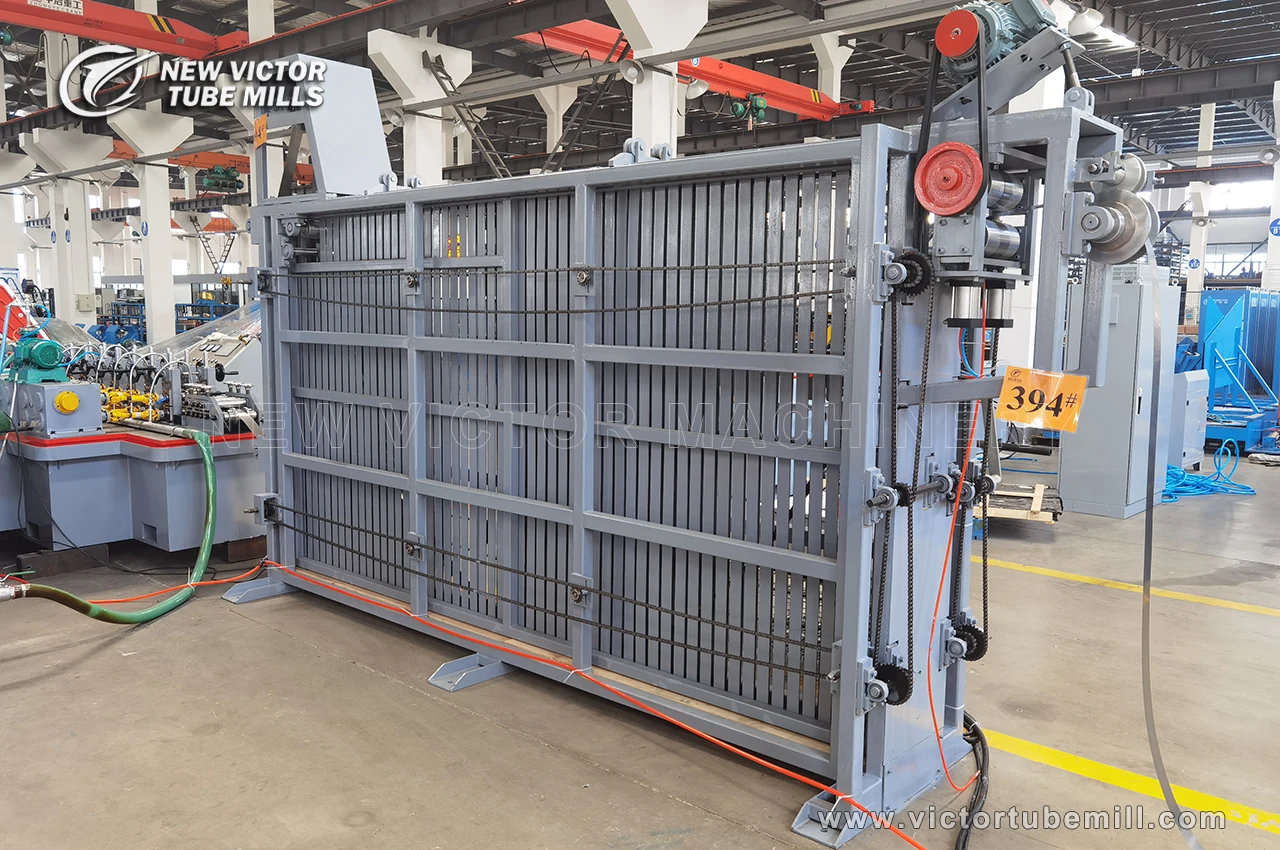

ERW tube milling machine steel pipe making machine entry section

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600568509217

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the ERW tube milling machine steel pipe making machine entry section?

The primary function of the ERW tube milling machine entry section is to support the strip coil and feed the strip into the flattener, ensuring a continuous production of steel pipes.

2. What types of uncoilers are available with this machine?

The machine offers different types of uncoilers, including single-head hydraulic uncoilers, double-head pneumatic uncoilers, and double-head hydraulic uncoilers.

3. How does the loop accumulator contribute to the tube mill production line?

The loop accumulator stores enough steel strip between the shear welder and the host to ensure that the production line can run continuously without interruptions.

4. What welding technology is used in the connection of strips?

The strips are connected using CO2 gas shielding welding, which ensures a strong and continuous weld between the coil tail end and the succeeding coil top end.

5. Can the uncoiler be operated manually?

Yes, the uncoiler can be operated manually, as well as pneumatically and hydraulically, depending on the model chosen.

6. What is the role of the flattening machine in the milling process?

The flattening machine is used to flatten the strip steel before it enters the forming and sizing machine, ensuring uniformity in the tube production process.

7. Is the entry section suitable for different types of steel strips?

Yes, the entry section is designed to accommodate various types of steel strips, making it versatile for different production needs.

8. What is the advantage of using a double-head uncoiler?

A double-head uncoiler allows for continuous operation by enabling the use of two coils simultaneously, which minimizes downtime during coil changes.

9. How does the shearer and butt welder function in the production line?

The shearer and butt welder cut the preceding coil tail end and weld it to the succeeding coil top end, facilitating a seamless transition in the production process.

10. What is the maximum capacity of the uncoiler?

The maximum capacity of the uncoiler can vary based on the model, and it's important to consult the product specifications for detailed information.

11. Is training provided for operating the milling machine?

Yes, training is typically provided for operators to ensure they can efficiently and safely operate the milling machine and its components.

12. What maintenance is required for the uncoiler?

Regular maintenance such as checking hydraulic fluids, lubricating moving parts, and ensuring proper alignment is essential for the uncoiler's optimal performance.

13. Can the machine be integrated with existing production lines?

Yes, the ERW tube milling machine entry section can often be integrated with existing production lines, but specific compatibility should be confirmed.

14. What types of materials can be processed with this machine?

The machine is designed to process various types of steel strips, making it suitable for a wide range of steel pipe manufacturing applications.

15. What are the safety features included in the machine?

Safety features typically include emergency stop buttons, safety guards, and sensors to prevent accidents during operation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading