B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 27 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is an Electrodialysis machine used for?

An Electrodialysis machine is used to purify and separate substances using selective membranes and electrodes. It is commonly utilized for seawater desalination, wastewater treatment, and the recovery of useful substances from industrial processes.

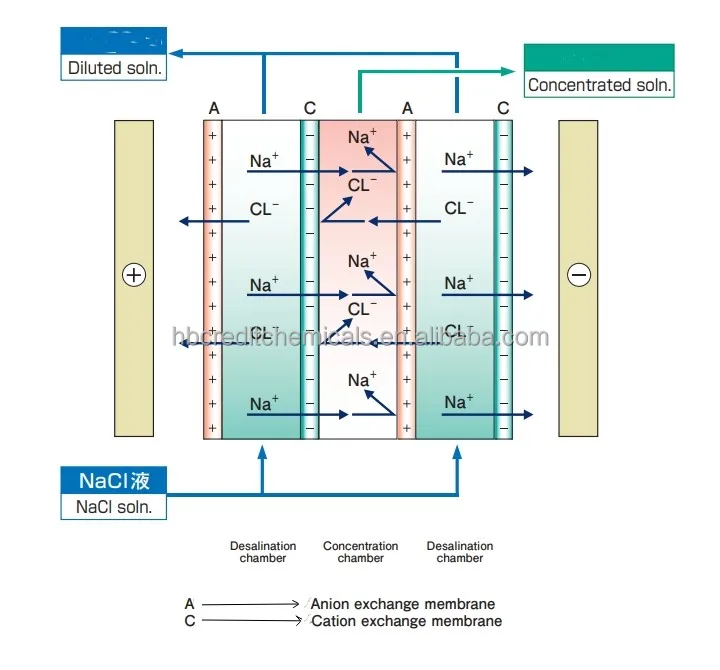

2. How does the Electrodialysis process work?

Electrodialysis works by applying an electric field to a solution containing charged solute particles, such as ions. These ions migrate through a semipermeable membrane, allowing for the separation and purification of different substances.

3. What are the applications of Electrodialysis machines?

Electrodialysis machines are widely used in various industries including chemical, light industry, metallurgy, papermaking, and healthcare. They are especially important for pure water preparation and environmental protection through the treatment of wastewater.

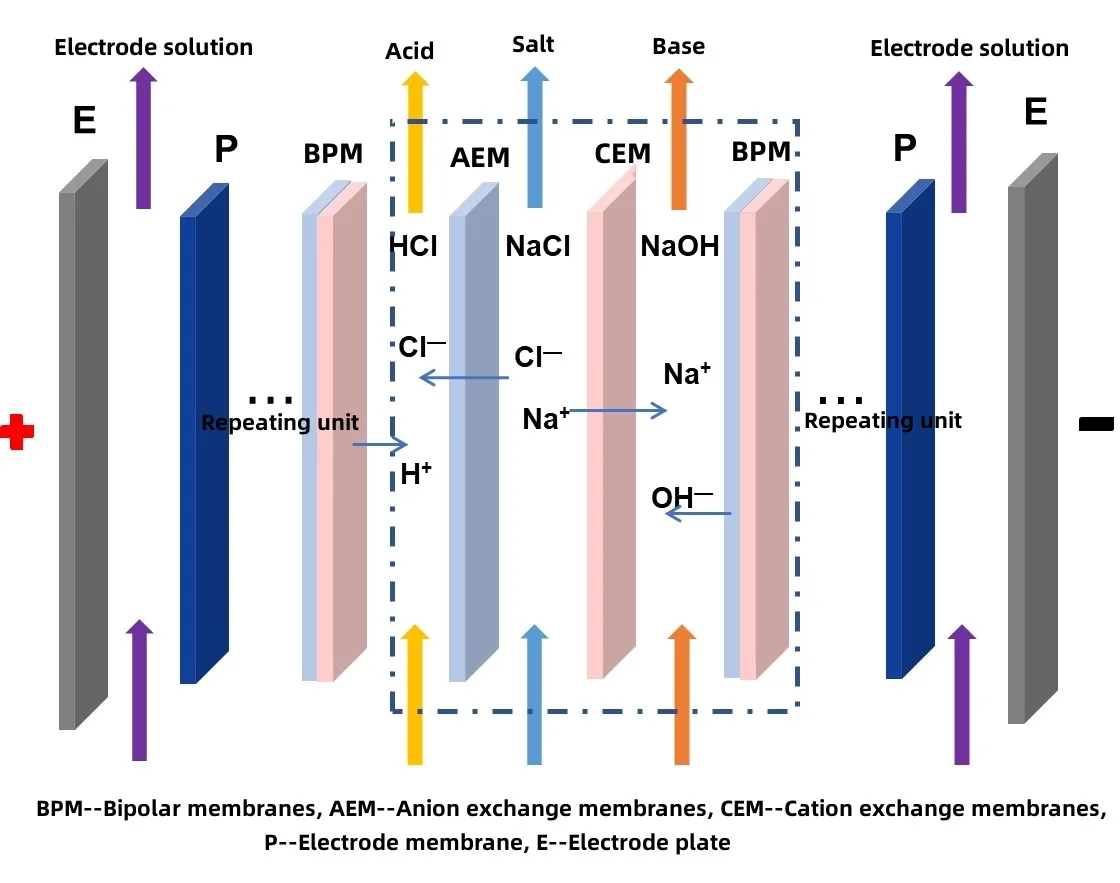

4. What is bipolar membrane electrodialysis?

Bipolar membrane electrodialysis (BMED) utilizes a bipolar membrane that can electro-dissociate water into H+ and OH− ions under an electric field. This method is effective for converting waste salts into acids and bases.

5. What are the benefits of using an Electrodialysis machine?

Benefits include efficient separation of ions, reduction of operational costs in wastewater treatment, and environmentally friendly processes for recovering valuable substances from waste streams.

6. Is Electrodialysis effective for wastewater treatment?

Yes, Electrodialysis is highly effective for wastewater treatment, particularly for recovering acids and alkalis from industrial waste and reducing harmful substances in the effluent.

7. Can Electrodialysis be used for seawater desalination?

Absolutely. Electrodialysis is one of the technologies used for seawater desalination, effectively separating salt from water to produce fresh water.

8. What types of membranes are used in Electrodialysis machines?

Electrodialysis machines use selective membranes, specifically cation and anion exchange membranes, as well as bipolar membranes for specific applications like BMED.

9. How does Electrodialysis compare to other water purification methods?

Electrodialysis is often more energy-efficient than traditional methods like reverse osmosis, especially for specific applications such as the recovery of ions and salts from solutions.

10. What kind of maintenance does an Electrodialysis machine require?

Maintenance typically involves regular cleaning of membranes, monitoring of electrical connections, and ensuring that the system is free from blockages or fouling.

11. Is Electrodialysis technology environmentally friendly?

Yes, Electrodialysis is considered environmentally friendly, as it reduces waste and allows for the recovery of valuable substances from industrial processes, minimizing pollution.

12. What industries benefit the most from Electrodialysis technology?

Industries such as chemical manufacturing, metallurgy, papermaking, and wastewater treatment are among the primary beneficiaries of Electrodialysis technology.

13. Can Electrodialysis recover valuable materials from industrial wastewater?

Yes, Electrodialysis can recover valuable materials, such as acids and bases, from industrial wastewater, making it a cost-effective solution for material recovery.

14. What are the safety considerations when operating an Electrodialysis machine?

Safety considerations include ensuring proper electrical connections, using protective gear when handling chemicals, and following operational guidelines to prevent accidents.

15. How long does it take to see results from an Electrodialysis process?

The time to see results from Electrodialysis can vary depending on the specific application and concentration of solutes, but it generally provides rapid separation and purification.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading