B21, China Town Mall, Midrand

Easy To Operate Automatic Horizontal Pillow Pasta Spaghetti Packaging Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600473492469

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Easy To Operate Automatic Horizontal Pillow Pasta Spaghetti Packaging Machine used for?

It is a horizontal pillow-style flow wrapper designed for high-speed packing of pasta, spaghetti, noodles and similar dry food products into sealed pillow bags.

2. What models are available and how do they differ?

Three models are listed: HS-250, HS-320 and HS-350. They differ mainly by maximum film width and bag width/length ranges. HS-250 supports up to 250 mm film, HS-320 up to 320 mm, and HS-350 up to 350 mm with corresponding bag size and product height capacities.

3. What are the machine's packing speed and production capacity?

Packing speed ranges from 40 to 230 bags per minute depending on product, bag size and settings.

4. What bag sizes can the machine produce?

Bag length: HS-250/HS-320 65–280 mm (HS-350 up to 330 mm). Bag width: HS-250 30–110 mm, HS-320 30–150 mm, HS-350 50–160 mm. Product height max is 40 mm for HS-250/320 and 45 mm for HS-350.

5. What film types and widths are compatible?

The machine accepts a wide range of packaging films used for dry foods (e.g., CPP, BOPP, laminates). Maximum film widths: 250 mm (HS-250), 320 mm (HS-320), 350 mm (HS-350). Always test specific film constructions for seal quality.

6. What is the maximum film roll diameter?

The maximum film roll diameter for all models is 320 mm.

7. What are the electrical and power requirements?

Standard specification: 220 V, 50/60 Hz, total power about 2.4 kW. Confirm site power compatibility and grounding before installation.

8. How user-friendly is setup and changeover?

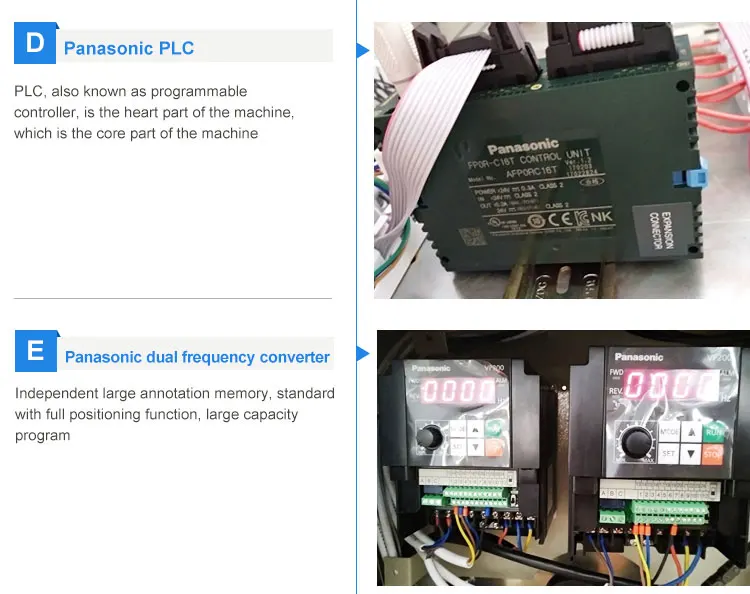

The machine features a Human–Machine Interface (HMI) for quick parameter entry and program-controlled operations. Double motor/Panasonic transducer control allows flexible bag length settings and precise cutting to minimize changeover time.

9. How does the machine ensure accurate cutting and sealing on printed films?

It uses a high-sensitivity optical color mark tracking system and precise film positioning so the machine stops in selected positions, ensuring accurate sealing/cutting even on printed films.

10. What diagnostics and controls are included?

The machine has a self-diagnosis function that displays faults for faster troubleshooting and a separate PID temperature control system for stable sealing across different materials.

11. Is the machine suitable for food-grade operations and easy to clean?

Yes — it is designed for food packaging. Surfaces in contact with product/film are made for hygienic use. Routine cleaning and sanitation should follow your facility’s food-safety procedures; request specific cleaning recommendations from the supplier for your model.

12. What maintenance and spare-parts support is available?

The machine has a simple and reliable driving system for easy maintenance. Suppliers typically offer spare parts, service and maintenance guidance — contact the vendor to arrange spare-part kits and service contracts.

13. Can this machine be integrated with upstream feeding or dosing systems?

Yes — it can be integrated with automatic feeders, vibratory or mechanical dosing and conveying systems for continuous high-speed operation. Discuss your product and line requirements with the supplier for best integration options.

14. What warranty, installation and training options are provided?

Warranty terms, installation and training vary by supplier. Many vendors provide commissioning, operator training and after-sales service packages — contact the seller for specific warranty coverage, on-site installation and training details.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading