B21, China Town Mall, Midrand

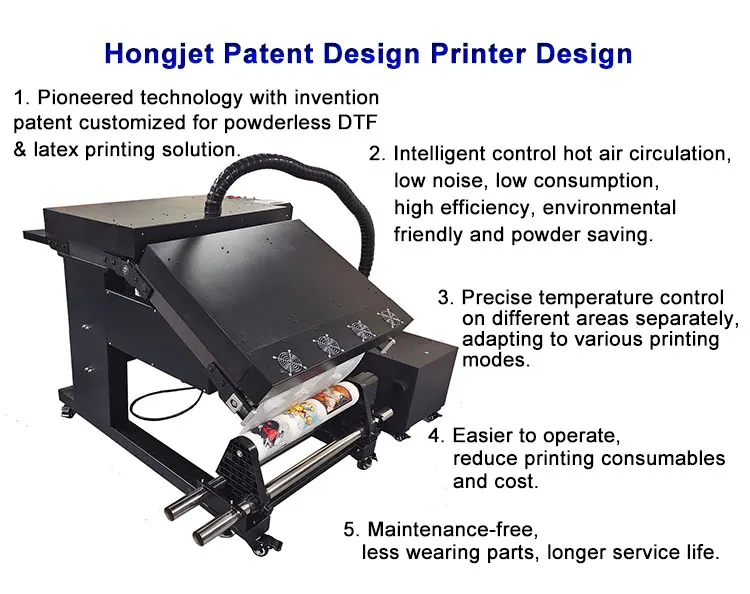

DTF inkjet printer heat transfer t-shirt printing machine

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 1600924080784

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of materials can the DTF inkjet printer print on?

The DTF inkjet printer can print on various materials, including T-shirts, leather, and other fabrics, making it versatile for different applications.

2. How does the DTF printing process work?

The DTF printing process involves three main steps: printing, drying, and transferring, without the need for a powder shaking step, which reduces defects.

3. What is the printing speed of the DTF printer?

The printing speed varies depending on the mode: in economy mode, it prints at 12 m²/h; in production mode, 8 m²/h; and in quality mode, 6 m²/h.

4. Is the DTF printer easy to operate?

Yes, the DTF printer is fully automatic, designed for ease of use, ensuring efficient and consistent results without requiring extensive training.

5. What printhead models are used in the DTF printer?

The DTF printer is equipped with 3 or 4 Epson I3200 printheads, known for their high precision and excellent color output.

6. What is the power requirement for the DTF printer?

The DTF printer is compatible with both 110V and 220V power sources, operating at AC 220V/50-60Hz with a maximum current of 10A.

7. What is the maximum printing width of the DTF printer?

The maximum printing width of the DTF printer is 600 mm.

8. How does the printer handle white ink?

The DTF printer features an intelligent automatic circulation mixing system for white ink, ensuring consistent quality and performance.

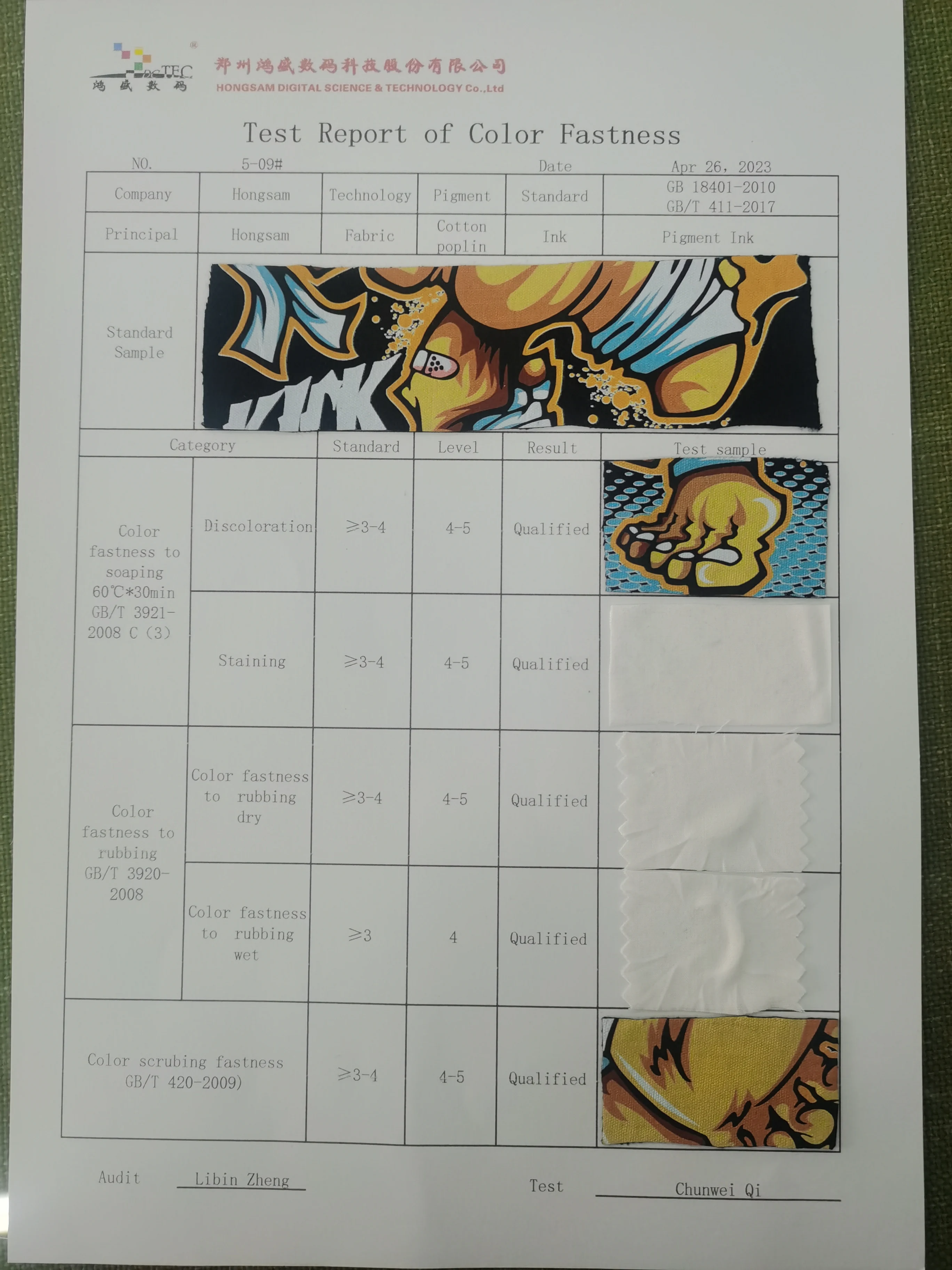

9. What kind of ink does the DTF printer use?

The DTF printer utilizes textile ink, which is designed specifically for vibrant and durable prints on various fabrics and materials.

10. Can the DTF printer be used for home printing?

Yes, the DTF printer is suitable for home use as well as for garment and printing shops, providing a versatile printing solution for different needs.

11. What is the weight of the DTF printer?

The DTF printer has a robust structure with a weight of 210kg, ensuring stability during operation.

12. What are the recommended working conditions for the DTF printer?

The ideal working environment for the DTF printer is a temperature of 20-30°C and humidity levels between 35% and 65%.

13. What software is compatible with the DTF printer?

The DTF printer works with various RIP software, including RIIN, MainTop, and PhotoPrint, for optimal printing results.

14. How does the printer ensure print head protection?

The DTF printer includes an intelligent dual-side high sensitivity anti-scratch system to protect the print heads during operation.

15. What are the advantages of using DTF printing technology?

DTF printing technology offers vibrant colors, durability, no need for powder shaking, and efficient printing processes, making it an excellent choice for high-quality textile printing.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading